Titanium Billet Turbo Compressor Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Titanium Billet Turbo Compressor Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

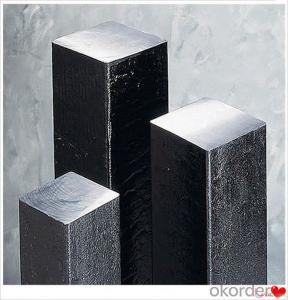

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

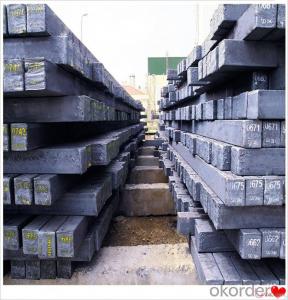

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets inspected for surface defects?

- Steel billets are inspected for surface defects through visual inspection, magnetic particle inspection, and ultrasonic testing. Visual inspection involves a thorough examination of the surface for any visible defects such as cracks, pits, or rough spots. Magnetic particle inspection uses magnetic particles and a magnetic field to identify any surface or near-surface defects that may not be visible to the naked eye. Ultrasonic testing utilizes high-frequency sound waves to identify internal and surface defects by analyzing the reflected waves. These inspection methods ensure the quality and integrity of steel billets before further processing.

- Q: How are steel billets used in the production of fasteners?

- Steel billets are used in the production of fasteners as they serve as the raw material for manufacturing various types of fasteners such as bolts, screws, and nuts. These billets are heated and then forged or rolled to shape them into the desired fastener form. The resulting fasteners possess high strength and durability, making them suitable for a wide range of applications in industries like construction, automotive, and manufacturing.

- Q: What are the common sizes of steel billets?

- Common sizes of steel billets vary depending on the specific application and industry. However, some commonly used sizes include 100mm x 100mm, 120mm x 120mm, and 150mm x 150mm. These sizes are often used in industries such as construction, automotive, and manufacturing.

- Q: What are the main factors that influence the strength of steel billets?

- The strength of steel billets is impacted by various factors, including the chemical composition, heat treatment, and microstructure of the steel. The chemical composition plays a significant role in determining the strength of steel billets. Alloying elements like carbon, manganese, silicon, and chromium can enhance strength by forming solid solutions or precipitates that increase hardness and tensile strength. It is crucial to control impurity levels and maintain the desired balance of alloying elements to achieve the desired strength properties. Heat treatment is another important factor that affects the strength of steel billets. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. It significantly impacts the microstructure of the steel, which ultimately influences its strength. For example, quenching and tempering can result in the formation of desired microstructures like martensite or bainite, which enhance strength and toughness. The microstructure of steel billets also plays a crucial role in determining their strength. The arrangement of crystal grains and the presence of different phases within the steel greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features like precipitates or second-phase particles can contribute to the strength of steel billets. Other factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can also affect the strength of steel billets. These factors impact grain size, grain boundary density, and defect concentration, all of which influence the mechanical properties of the steel. In conclusion, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: How are steel billets used in the production of power transmission equipment?

- Steel billets are used in the production of power transmission equipment as they are heated and shaped into various components such as gears, shafts, and couplings. These billets provide the necessary strength and durability required for these equipment to handle high power loads and transmit energy efficiently.

- Q: How are steel billets used in the production of oil and gas equipment?

- Steel billets are an essential component in the production of oil and gas equipment. These billets are semi-finished steel products that are typically square or rectangular in shape, and they serve as the primary raw material for manufacturing various oil and gas equipment. Firstly, steel billets are used in the production of pipes, which are crucial for transporting oil and gas from the extraction sites to refineries or distribution points. Billets are heated and then rolled into seamless or welded pipes, depending on the specific requirements. These pipes are designed to withstand high pressure, corrosive environments, and extreme temperatures, making them suitable for transporting oil and gas through pipelines over long distances. Additionally, steel billets are used in the manufacturing of valves and fittings, which are integral components of oil and gas equipment. Valves control the flow of oil and gas within pipelines, allowing for regulation and shut-off when necessary. Fittings, such as connectors and couplings, ensure the proper connection and alignment of different pipe sections. These components are typically forged or machined from steel billets to ensure strength, durability, and resistance to harsh operating conditions. Furthermore, steel billets are utilized in the production of drilling equipment, such as drill bits, drill collars, and drill pipes. These components are subjected to extreme forces and abrasive environments during the drilling process. Steel billets are forged, heat-treated, and machined to create these drilling tools, ensuring they can withstand the demanding conditions encountered during oil and gas exploration. In summary, steel billets play a crucial role in the production of oil and gas equipment. They are used to manufacture pipes, valves, fittings, and drilling equipment, which are essential for the extraction, transportation, and processing of oil and gas. The high strength, durability, and resistance to harsh conditions make steel billets an ideal raw material for constructing reliable and efficient equipment in the oil and gas industry.

- Q: Iron type frequency furnace, billet 150, continuous casting billet between the hole, please help net friend to find the original, please ask non answer, not Xie, please mention, understand enough, please resume me

- 1: new furnace, new furnace lining contains more gas2: raw material no clean, no coincidence?3: melt protection? Temperature is not high, no refining and static?4:3 point, mold and traction to look for defects, mold cooling effect - water temperature - traction line and horizontal - traction process5: stop and pull

- Q: What are the different types of defects that can occur during steel billet production?

- During steel billet production, various types of defects can occur that may affect the quality and performance of the final product. Some of the common defects observed in steel billets are: 1. Surface Defects: These defects occur on the surface of the billet and can include scales, cracks, pits, scars, and slivers. Surface defects can be caused by improper handling, poor lubrication, inadequate heating, or contamination during the manufacturing process. 2. Internal Defects: Internal defects occur within the billet and can be more challenging to detect. Examples of internal defects include voids, porosity, inclusions, and segregation. Internal defects can arise due to improper alloying, inadequate mixing, or improper casting and solidification processes. 3. Shape Defects: Shape defects refer to any deviation from the desired dimensions or geometry of the billet. These defects can include bending, bowing, twisting, or excessive tapering. Shape defects can be caused by improper rolling or cooling processes, inadequate maintenance of rolling equipment, or poor billet handling. 4. Chemical Composition Defects: Steel billets must meet specific chemical composition requirements to ensure desired material properties. Defects in chemical composition can occur due to improper mixing of raw materials, incorrect temperature control, or contamination during the manufacturing process. These defects can negatively impact the mechanical properties, such as strength, ductility, or corrosion resistance, of the final product. 5. Incomplete Solidification: Incomplete solidification can lead to defects like centerline segregation or shrinkage cavities. These defects occur when the cooling rate is too fast or uneven, preventing the complete solidification of the billet. Incomplete solidification can weaken the billet structure, affecting its overall integrity and performance. 6. Dimensional Defects: Dimensional defects refer to deviations in the size, length, width, or thickness of the billet. These defects can occur due to inaccurate measurement or control during the manufacturing process. Dimensional defects can impact the fitment or compatibility of the billet in subsequent processes or applications. It is crucial for steel billet manufacturers to implement stringent quality control measures to minimize the occurrence of these defects. Regular inspections, process optimization, and adherence to industry standards and best practices can help mitigate defects and ensure the production of high-quality steel billets.

- Q: What is the role of steel billets in the manufacturing of automotive transmission systems?

- The manufacturing of automotive transmission systems heavily relies on steel billets, which serve as essential raw material forms of steel. These billets act as the foundation for shaping and forming various components of the transmission system. The production of gears, shafts, and other critical transmission components is one of the primary purposes of steel billets in the manufacturing process. These billets are either forged or machined to achieve the desired shape, strength, and dimensional accuracy necessary for these components. By utilizing steel billets, manufacturers ensure that these parts possess the required strength, durability, and resistance to wear and tear, which are crucial for the proper functioning of the transmission system. Additionally, steel billets also find application in the manufacturing of transmission casings. These casings serve as protective housing for the internal components of the transmission system. To create these casings, steel billets are cast or molded into the desired shape, guaranteeing that they possess the necessary strength and rigidity to withstand the forces and stresses experienced by the transmission system. Furthermore, the use of steel billets allows for the customization and optimization of transmission system components. Manufacturers have the freedom to select specific grades of steel billets based on their desired properties, such as hardness, toughness, or corrosion resistance. This flexibility enables the production of transmission systems that meet the specific requirements of different automotive applications, whether it involves high-performance vehicles or heavy-duty trucks. In conclusion, steel billets play a vital role in the manufacturing of automotive transmission systems. They provide the raw material needed to create gears, shafts, casings, and other components. Steel billets ensure the strength, durability, and customization potential necessary to produce reliable and efficient transmission systems for various automotive applications.

- Q: What is the cost of producing steel billets?

- The production cost of steel billets can vary depending on different factors, such as the quality of the raw materials used, the production process employed, and the market conditions. Typically, the cost of producing steel billets includes several components. Firstly, there is the cost of raw materials, which usually consist of iron ore, coal or coke, and other alloying elements. The prices of these materials can change due to global market dynamics and availability. Secondly, the cost of energy is a significant factor in steel billet production. This includes the cost of electricity and fuel needed for the manufacturing process, such as powering the blast furnaces or electric arc furnaces used to melt the raw materials. Thirdly, labor costs play a crucial role in the overall production cost. This includes wages for skilled and unskilled workers involved in operating the machinery, maintaining equipment, and overseeing the production process. In addition, there are indirect costs that need to be taken into account, such as expenses for machinery maintenance and repair, transportation costs for raw materials and finished products, and overhead costs related to administrative functions. It is important to note that external factors like government regulations, tariffs, and taxes can also influence the production cost of steel billets. Furthermore, market demand and competition can impact pricing strategies and ultimately affect production costs. Therefore, providing an exact cost figure for producing steel billets is challenging due to constant fluctuations. It is best to consult industry experts or steel manufacturers for the most accurate and up-to-date information on production costs.

Send your message to us

Titanium Billet Turbo Compressor Wheel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords