Stainless Steel 304 sheet and plate with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel 304 sheet and plate with top quality

Description of Stainless Steel 304 sheet and plate with top quality:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel 304 sheet and plate with top quality:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel 304 sheet and plate with top quality:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel 304 sheet and plate with top quality:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel 304 sheet and plate with top quality:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel 304 sheet and plate with top quality:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

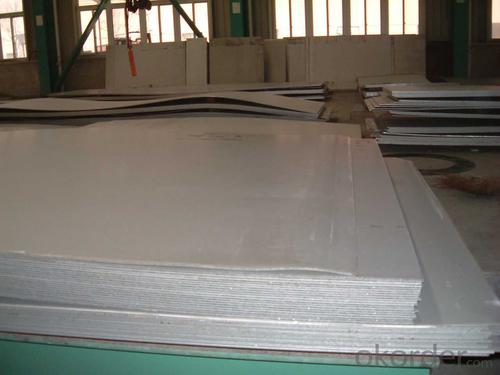

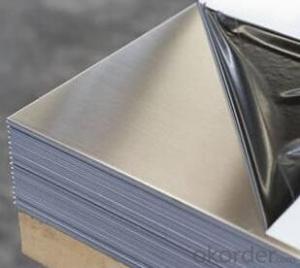

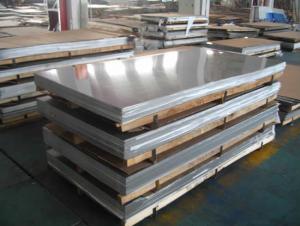

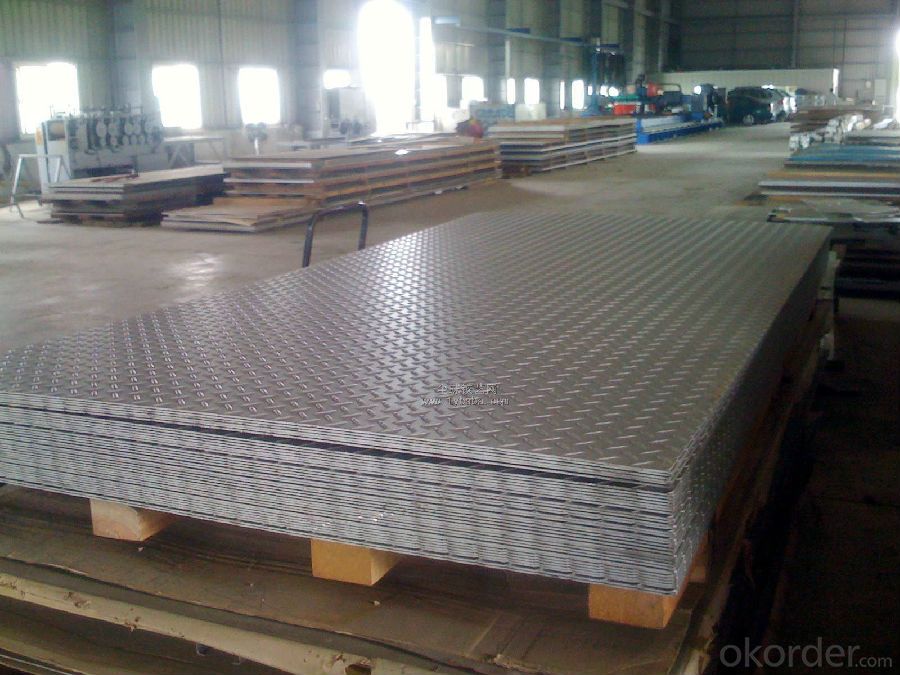

Images of Stainless Steel 304 sheet and plate with top quality:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: Are stainless steel sheets suitable for automotive applications?

- Stainless steel sheets are indeed well-suited for automotive applications. With its durability, strength, and corrosion resistance, stainless steel proves to be an ideal material for various automotive components. It finds extensive use in body panels, exhaust systems, trim, and other parts that necessitate resistance to weathering, heat, and chemical exposure. Moreover, stainless steel sheets offer remarkable aesthetic appeal as they can be polished to a mirror-like finish or brushed to achieve a sleek and contemporary appearance. Additionally, stainless steel is easily malleable, enabling the production of intricate shapes and designs crucial in the automotive manufacturing process. All in all, stainless steel sheets provide the essential properties and versatility to fulfill the demanding requirements of automotive applications.

- Q: Can stainless steel sheets be cut or shaped easily?

- Yes, stainless steel sheets can be cut or shaped easily. Stainless steel is known for its excellent machinability and workability, making it relatively easy to cut, shape, and form into desired shapes or sizes with the right tools and techniques.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To regain the luster or polish on stainless steel sheets, there are several approaches you can attempt: 1. Warm water and soap cleanse: Initiate the process by washing the stainless steel sheets with warm water and a mild dish soap. Employ a soft cloth or sponge to delicately scrub the surface, then rinse it with clean water and meticulously dry it with a clean cloth. This procedure should eliminate any dirt or grime that is dimming the shine. 2. Vinegar solution: In case the stainless steel sheets possess obstinate stains or lackluster spots, you can experiment with a vinegar solution. Combine equal parts of white vinegar and water in a spray bottle, then spritz the solution onto the surface. Allow it to sit for a few minutes, then wipe it away with a soft cloth. Vinegar aids in stain removal and rejuvenates the shine of stainless steel. 3. Baking soda paste: For more stubborn stains or scratches on the stainless steel sheets, you can concoct a paste using baking soda and water. Blend an ample amount of baking soda with water until a thick paste forms, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and meticulously dry it. 4. Stainless steel cleaner: There are commercially available stainless steel cleaners that are specifically formulated to restore the shine and finish of stainless steel. Adhere to the instructions on the cleaner and administer it to the surface using a soft cloth or sponge. Gently rub in the direction of the grain and rinse with water. To prevent water spots, ensure thorough drying. Always remember to test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This precaution will help ensure that the method or solution does not cause any damage or discoloration.

- Q: How many steps do I need for stamping the stainless steel plate?

- Among the world's steel products, 60 to 70% are plates, most of which are finished by pressing. The car body, chassis, fuel tank, radiator plate, boiler drum, container shell, motor, electrical equipment, iron core, silicon steel sheet and so on are all stamping processing. Instruments and meters, household appliances, bicycles, office machinery, household utensils and other products, there are a large number of stamping parts.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent pitting or crevice corrosion on stainless steel sheets: 1. It is crucial to choose the right grade of stainless steel, as grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Ensuring a smooth and clean surface is essential. Corrosion can be initiated by rough surfaces or scratches. Creating a smoother surface can be achieved by polishing or electropolishing the stainless steel sheets. 3. Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Pitting and crevice corrosion are intensified in stagnant environments, so proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Additionally, proper ventilation and humidity control can help reduce the risk of corrosion. 6. Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections should be conducted to detect any signs of corrosion early on. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

- Q: What is the thermal expansion coefficient of stainless steel sheets?

- The thermal expansion coefficient of stainless steel sheets is subject to variation based on the specific grade and composition of the stainless steel. In comparison to other metals, stainless steel generally possesses a lesser thermal expansion coefficient. The typical range for the coefficient of thermal expansion in stainless steel sheets falls between 10.8 x 10^-6 to 18.0 x 10^-6 per degree Celsius. It should be noted that this coefficient may undergo slight variation among different stainless steel alloy types.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- There are several different types of stainless steel sheet finishes that are commonly used in automotive applications. These finishes are designed to provide both aesthetic appeal and functional benefits for the automotive industry. 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a rough, dull appearance. It is commonly used in non-decorative applications where corrosion resistance is the primary concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is commonly used for automotive trim and decorative applications. It has a smooth surface and a moderate level of reflectivity. 3. No. 3 Finish: This is a semi-polished finish that is achieved by using progressively finer abrasives. It has a moderate level of reflectivity and is commonly used for decorative applications where a shinier appearance is desired. 4. No. 4 Finish: This is a brushed finish that is achieved by polishing the stainless steel sheet with a fine-grit abrasive. It has a consistent, linear grain pattern and a moderate level of reflectivity. It is commonly used for decorative applications such as trim and accents. 5. No. 8 Mirror Finish: This is a highly polished finish that is achieved by buffing the stainless steel sheet with a series of abrasive compounds. It has a mirror-like appearance and is commonly used for decorative applications that require a high level of reflectivity. In addition to these standard finishes, there are also specialty finishes available for automotive applications, such as embossed, patterned, or textured finishes. These finishes can provide unique design elements and enhance the overall aesthetic appeal of the vehicle. Overall, the choice of stainless steel sheet finish for automotive applications depends on the specific requirements of the project, including factors such as corrosion resistance, durability, and desired appearance.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

- Q: What is the maximum length of a stainless steel sheet?

- The potential length of a stainless steel sheet is subject to various factors, such as manufacturing capabilities, supplier limitations, and transportation constraints. Typically, stainless steel sheets can be manufactured in lengths spanning from a few feet to several hundred feet. Nevertheless, it should be emphasized that longer lengths might pose challenges in terms of handling and transportation, potentially affecting their availability and cost. Moreover, customized orders or specific applications could permit even lengthier stainless steel sheets. Thus, consulting with manufacturers or suppliers is advisable to ascertain the precise maximum length options offered for stainless steel sheets.

- Q: Can stainless steel sheets be used in the automotive industry?

- Indeed, the automotive industry does have the capability to employ stainless steel sheets. Owing to their remarkable strength, durability, and resistance to corrosion, stainless steel is frequently utilized in the assembly of automotive components. Exhaust systems, fuel tanks, bumpers, and trim are common examples of parts that are often crafted from this material. The utilization of stainless steel sheets grants manufacturers a great deal of flexibility in terms of design options, enabling them to fashion intricate forms and structures. Furthermore, due to its aesthetic appeal and ease of upkeep, stainless steel remains a favored choice in the automotive industry.

Send your message to us

Stainless Steel 304 sheet and plate with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords