Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

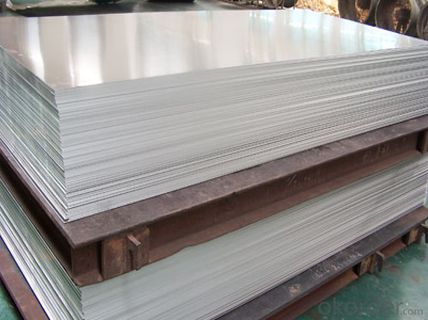

Stainless Steel Plate Sheet in Bulk Sale

Product Description

Description | steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | By bulk vessel OR By container OR as customers' requirement |

Delivery time | 2-3 weeks after reciept the L/C OR T/T |

Quality | No.1 |

Productivity | 1000 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

FAQ

Q: Why should you choose us:

A: 1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Advantages

Provide one-step purchase service to save your time, money and energy

Competive price, superior quality,and excellent logistics arrangement

Complete production line to provide full set products

Experienced facotry specialize in Building material

Professional Service team

Picture

- Q: How is stainless steel wire mesh woven?

- Stainless steel wire mesh is woven using a process called plain weave or twill weave. In the plain weave method, the wires are woven in a crisscross pattern, with each wire passing over and under the adjacent wires in an alternating manner. This creates a simple and tight mesh structure. On the other hand, in the twill weave method, the wires are interlaced in a diagonal pattern, which gives the mesh a more robust and durable construction. This weaving technique involves each wire passing over two and under two adjacent wires, creating a distinctive diagonal pattern. Both plain weave and twill weave methods require precision and attention to detail to ensure a consistent and uniform mesh structure. The wires used in stainless steel wire mesh are usually thin and strong, allowing for a tightly woven and reliable mesh that is resistant to corrosion and wear. Overall, the process of weaving stainless steel wire mesh involves interlacing thin stainless steel wires in either a crisscross or diagonal pattern, resulting in a versatile and durable mesh that finds applications in various industries such as filtration, screening, and protection.

- Q: What are the different surface coatings available for stainless steel wire?

- Stainless steel wire can be coated with various surface coatings, each with its own advantages and uses. Some commonly used coatings include: 1. Nickel plating: This coating enhances corrosion resistance and durability, making it suitable for marine and chemical-exposed environments. 2. Zinc plating: Zinc coating protects against corrosion and is often applied to stainless steel wire used outdoors or in industrial settings. 3. Epoxy coating: Stainless steel wire is coated with epoxy to create a barrier against corrosion, abrasion, and chemical exposure. Industries like food processing, pharmaceuticals, and medical devices commonly utilize this coating. 4. PTFE (Polytetrafluoroethylene) coating: Known as Teflon coating, PTFE provides a non-stick surface and reduces friction on stainless steel wire. It finds applications in conveyor belts and medical equipment. 5. Nylon coating: Nylon coatings offer excellent abrasion resistance and electrical insulation properties. They are ideal for abrasive environments and situations requiring electrical insulation. 6. Powder coating: This coating is applied as a dry powder and then cured through heat, forming a protective layer on stainless steel wire. It provides durability, chemical resistance, and can be customized in various colors for aesthetic purposes. The selection of a surface coating for stainless steel wire depends on specific application requirements, including desired corrosion resistance, durability, and functionality. It is crucial to consider factors such as the environment, chemical exposure, temperature, and more to choose the most suitable coating that ensures optimal performance and longevity for the stainless steel wire.

- Q: Can stainless steel wire be used for wire rope assemblies?

- Yes, stainless steel wire can be used for wire rope assemblies. Stainless steel wire is known for its high strength, corrosion resistance, and durability, making it an ideal choice for various applications, including wire rope assemblies. These assemblies are commonly used in industries such as construction, mining, maritime, and transportation, where strength and reliability are crucial. Stainless steel wire rope assemblies are resistant to rust and corrosion, allowing them to withstand harsh environmental conditions and prolonged exposure to moisture. Additionally, stainless steel wire rope assemblies offer excellent flexibility and can be customized to meet specific requirements, making them suitable for a wide range of applications.

- Q: What are the different types of stainless steel wire coatings?

- There are several different types of stainless steel wire coatings, including nylon, vinyl, epoxy, and PTFE (polytetrafluoroethylene). These coatings provide various benefits such as increased durability, corrosion resistance, insulation, and lubrication. The choice of coating depends on the specific application and desired properties.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- Drawing process will to some extent lose the thickness of stainless steel plate, usually at 0.1~0.2mm. In addition, because the human body, especially the palm has a relatively strong oil and sweat secretion, stainless steel wire drawing board often hand touch will leave a more obvious fingerprints, regular scrub.

- Q: Is stainless steel wire suitable for high-temperature applications?

- Yes, stainless steel wire is suitable for high-temperature applications. Stainless steel has excellent heat resistance properties, allowing it to maintain its strength and integrity even at elevated temperatures. It is commonly used in industries such as aerospace, automotive, and manufacturing, where high temperatures are involved.

- Q: What are the different wire shapes available in stainless steel wire?

- Stainless steel wire comes in various wire shapes, each with its own distinctive features and uses. The most common wire shapes include round wire, flat wire, square wire, and shaped wire. Round wire is the simplest and most widely utilized shape. It is versatile and suitable for a range of applications such as springs, mesh, and fencing. Its availability in various diameters allows for customization based on specific requirements. Flat wire, as the name implies, has a flat cross-section. It is frequently employed in applications where a low profile or limited space is essential, such as electrical connectors, screens, and micro springs. Square wire possesses a square cross-section, providing greater strength and stability compared to round wire. It is often utilized in applications requiring structural support or a more rigid wire, such as jewelry making and architectural uses. Shaped wire refers to wire that has been specially shaped or formed to meet specific design requirements. This can include wire with custom profiles like triangle, hexagon, or oval shapes. Shaped wire finds extensive use in specialized industries like automotive, aerospace, and medical, where precise specifications and unique designs are crucial. Apart from these basic shapes, stainless steel wire can undergo additional processing or modification techniques like annealing, tempering, and coating, which can enhance its properties and performance in specific applications. When selecting the appropriate wire shape, it is important to consider the specific needs and requirements of your project, as each shape offers distinct benefits and characteristics.

- Q: What are the different types of stainless steel wire springs used in the furniture industry?

- There are several types of stainless steel wire springs used in the furniture industry, including compression springs, extension springs, torsion springs, and zigzag or sinuous springs. Each type of spring has its own unique characteristics and is used for different purposes in furniture construction. Compression springs are commonly used in seat cushions to provide support and cushioning. Extension springs are often found in recliner mechanisms to assist with the reclining motion. Torsion springs are used in swivel chairs or adjustable seats to provide rotational resistance. Zigzag or sinuous springs are commonly used in upholstery to provide a comfortable and supportive seating surface.

- Q: What is stainless steel edge silk?

- Stainless steel wire, as the name suggests, is made of stainless steel wire, specifically consult wall stainless steel

- Q: What's the meaning of the 3 Series 4 series stainless steel wire?

- It's the 304 series304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 16% chromium, more than 8% of the nickel content. 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304, equivalent to our 06Cr18Ni9 [according to GB/T 20878-2007 has been changed to 06Cr19Ni10] stainless steel.

Send your message to us

Stainless Steel Plate Sheet in Bulk Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords