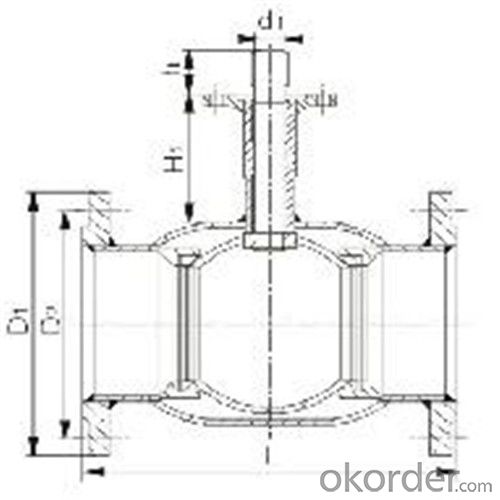

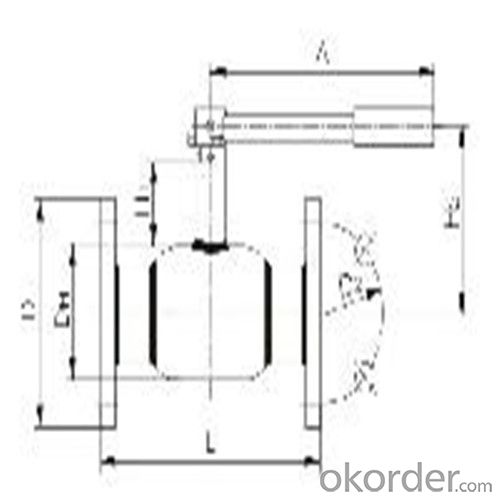

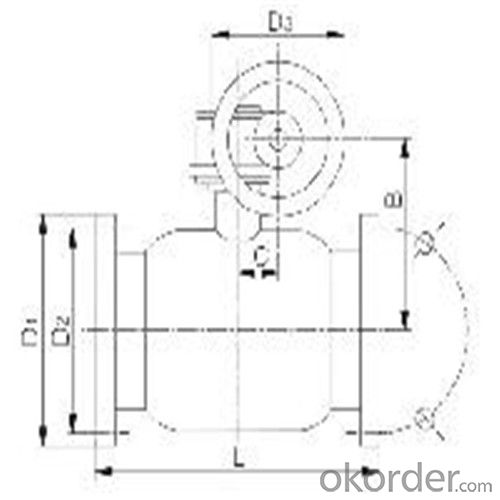

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

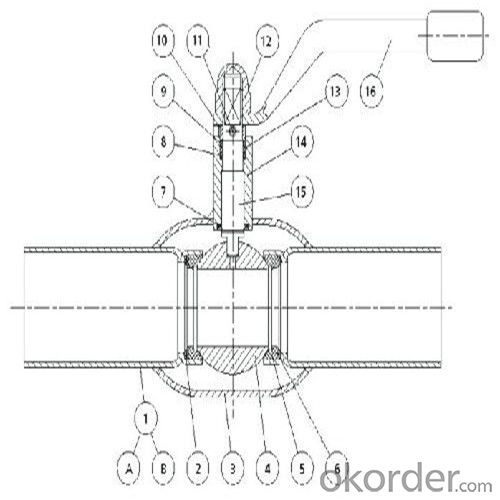

Product Description of Ball valve for heating supply:

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: non-return valves

- ..?..non-return valves..? I will assume that your 'non-return valves', are what is also known as check valves. Check valves allows flow in one direction only. These are used wherever you need to prevent backflow into the system, or to maintain a charged circuit with fluid, until you choose to unload(depressurize ) it. Now, why are they used in discharged lines of salt water, basically to prevent backflow....reason not known, here , requires usage info.

- Q: I need to know how to use a valve spring compressor, the type that looks like a c-clamp. I understand the fork side goes on top of the spring and the circular side goes on the valve to push and hold. There are also two little scoop things in the middle of the fork that i don't know what they are used for. If i can get a step by step instruction, you will get the best answer

- save yourself the hassle and throw that thing away go back to your local auto parts store and buy the l shaped spring compresser should be about twenty dollars make sure vehicle is at tdc remove rocker arm bolt remove rocker arms going valve by valve do not mix them up must go in exactly the same order they came out now lightly tap the top of valve with a rubber mallet will help loosen retainers place compresser on rocker arm stud take r.a. nut and tighten till valve locks fall out or can be removed very small dont lose use compressed air to hold valves in place at tdc sorry that should have been first not hard but not easy to do rebuilt 350 motor from the guts out spent alot of money on spring compressers only to find out the simplest one worked the best the one like u got will give u hell i tried napas version craftsman all of them trust me use the L bar

- Q: Are these valves are a kind of heart chambers pressure sensors?What is keeping them interlocked 2x2?

- It's all mechanical. The valves are passive things kind of like a screen door. When you push on them from one side they open, when you push on them from the other they close. The valves are assisted by some fibers attached to the inside of the heart similar to the way a screen door is helped by a spring attached to the door frame. It's the flowing blood that pushes the valves open or closed as the heart pumps. The path that the blood follows in the heart as it beats happens to make it so that the valves close two at a time. This is because the heart is actually four separate pumps that work two at a time. There's no direct electrical connection to the SA node. The only way they're connected is that the SA node firing is what causes the heart to pump, causing the blood to force the valves open.

- Q: so here are the details. i've been using my trumpet for about 6-8 years now and 1 if not 2 valves get stuck on my trumpet. the problem is not the oil as i have over oiled them too and no go. its that when i try to put my valves back in their place and twist them they don't stay in place,move ,and making either my valves stuck or making my trumpet not do a sound. what should i do? repair shop or buy a new one? i hear the clicking sound when i put them back but still all that does is either make my valve more sticky

- Your first step is to clean the valves and the casings. You'll need a casing brush or soft cloth you can run through the casing to clean them. Start with warm soapy water (dish washing soap) then clean them with alcohol--if you don't have alcohol use a water with a little vinegar added. You may need to let the valves soak a bit to loosen everything up. Remove the soap and alcohol from the casings and the tubing--rinse the valves and pat them dry. Inspect them for damage, if none is found then oil the valves and re-install them. If that doesn't work take it to a shop. Don't try lapping your valves yourself.

- Q: according to my study only indurial gate valves have both rising and non rising stem through handwheel and it seems that it doesnot apply to golbe valve and globe valves are only non rising stem. i wanted to know if this is right

- so non rising stem valves are usually used on only clean liquids long of stem is the same

- Q: In one of the two bathrooms - that we rarely used - I recently found that shower has now only hot water running. The valve is Moen brand with a single knob. On turning this, I get no cold water, but just hot water. I removed the knob, and decided to maybe replace the cartidge, but could not make any headway, after removing the acrylic knob. First, do I need to remove the cartridge?If yes, how? Is it possible to remove it without removing the back-plate glued to the Tile walls? Will appreciate detailed instructions to remove or fix the valve?thanks

- Only Hot Water In Shower

- Q: I'm picking up euphonium (brass instrument) after a 5 year hiatus. Can I still use my old valve oil and slide grease (Trombotine)?

- okorder /

- Q: Why can't i start my valve?

- what kind of valve are you talking about? A Valvo?? LOL...No really, what kind of valve? Valves do not start, once the engine is fired up then the valve becomes a part of the engines 4 cycle system of opening and closing to allow fuel and air to enter inside the combustion chamber and ignite the fuel to keep the engine running. good luck..

- Q: like they say on 4 strokes you gotta go get valve jobs, and they cost bout 300 they say? well what does the mechanic do? can it be done at home and your just adjusting them?

- A okorder /

- Q: The water inlet valve on my Kenmore washer leaks. Is there an easy way to replace it? Last time it broke they charged me over $100 to fix it.

- see if you can find a manuel on it also try tracing the wires that go to the valve and back track from there. there is also water level switches and tempture switches that might be messed up

Send your message to us

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords