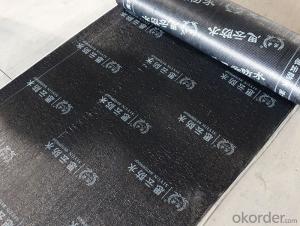

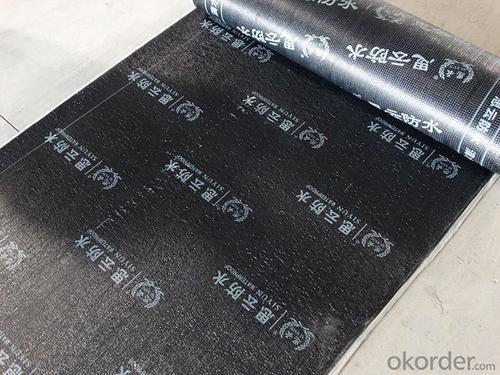

sbs app modified bitumen waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

thickness:

2.5mm,3mm,4mm,5mm

length:

7.5m-10m

width:

1m

top materials:

sand,PE,schist,aluminiue

Torched/torched applied SBS/APP modified bitumen waterproof membrane/bitumen waterproof membrane is widly used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Indeed, one can apply a waterproofing membrane to insulation surfaces. In fact, it is often advised to incorporate a waterproofing membrane above insulation as an extra layer of defense against water infiltration. This is particularly crucial in areas where moisture poses a concern, such as basements, roofs, or exterior walls. The waterproofing membrane functions as a barricade, preventing water from permeating the insulation and causing harm. It also aids in preserving the insulation's integrity and effectiveness by keeping it dry. Furthermore, certain waterproofing membranes have the added advantage of enhancing the insulation's energy efficiency by reducing air leakage and heat transfer. All in all, utilizing a waterproofing membrane on insulation surfaces is an intelligent and practical solution to safeguard your building or home from water damage.

- Q: Are waterproofing membranes suitable for wastewater treatment plants?

- Yes, waterproofing membranes are suitable for wastewater treatment plants. Wastewater treatment plants deal with the treatment and processing of wastewater, which contains a variety of chemicals, contaminants, and bacteria. These substances can be highly corrosive and can cause damage to the infrastructure of the plant if not properly protected. Waterproofing membranes provide an effective barrier against water and chemical penetration, preventing leaks, seepage, and corrosion. They can be applied to various areas of the plant, including tanks, basins, pipelines, and concrete structures. Additionally, waterproofing membranes are durable, long-lasting, and can withstand the harsh conditions and chemicals present in wastewater treatment plants. Therefore, using waterproofing membranes in wastewater treatment plants is a recommended practice to ensure the integrity, longevity, and efficiency of the infrastructure.

- Q: Sbs waterproof sheet and app coil how to see it

- At present, asphalt waterproofing membrane products in the domestic waterproof engineering applications, SBS, APP modified asphalt waterproofing membrane and asphalt composite tire waterproofing membrane applications accounted for more than 80% of the former SBS, APP modified asphalt waterproofing membrane in the quality And the price should be higher than the latter, is used for national one or two fortification of the permanent industrial and civil key projects in the high-end waterproof products, and asphalt composite tire waterproofing membrane is basically used for three or four fortification General civil engineering in the general product. Because the asphalt waterproofing membrane products in the appearance of the same basic, for the prevention of fish and pearl marketing and marketing, European products in the characteristics of these two types of products and identification methods to be analyzed. The following are the same as the

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Yes, waterproofing membranes are suitable for high-traffic areas. These membranes are designed to provide excellent durability and resistance against heavy foot traffic. They create a protective barrier that prevents water from seeping through and damaging the underlying structure. Additionally, waterproofing membranes can withstand the wear and tear caused by constant use, making them an ideal choice for areas with high foot traffic such as commercial spaces, parking garages, or outdoor walkways.

- Q: Can a waterproofing membrane be used for a garden pond?

- Indeed, a garden pond can benefit from the use of a waterproofing membrane. Specifically designed to prevent water seepage, this membrane offers an excellent solution for creating a watertight seal in the pond. By lining the pond with this material, one can effectively prevent water leakage and maintain the desired water level. Moreover, the use of a waterproofing membrane also serves to safeguard the pond liner against potential damage from roots, rocks, or other sharp objects, thereby extending the pond's lifespan. However, it is crucial to ensure that the chosen waterproofing membrane is completely safe for aquatic life and does not contain any harmful chemicals that may contaminate the pond water and adversely affect the plants and fish.

- Q: Can waterproofing membranes be used on concrete floors?

- Indeed, concrete floors can benefit from the utilization of waterproofing membranes. Within construction, these membranes hold a prevalent role in averting water infiltration and safeguarding the underlying structure. By implementing them onto concrete floors, a protective barrier arises, effectively thwarting water from permeating and causing harm. Significantly beneficial, waterproofing membranes prove their worth in spaces prone to water exposure, such as basements, bathrooms, and outdoor patios. Their presence ensures the concrete floor's durability while defending against moisture-related predicaments like cracking, spalling, and mold development.

- Q: Can a waterproofing membrane be used for a tunnel waterproofing system?

- Yes, a waterproofing membrane can be used for a tunnel waterproofing system. Waterproofing membranes are commonly used in construction projects to provide a barrier against water infiltration, and they can effectively prevent water from penetrating into tunnels, ensuring their long-term durability and structural integrity.

- Q: Can a waterproofing membrane be used for water tanks?

- Yes, a waterproofing membrane can be used for water tanks. Waterproofing membranes are specifically designed to prevent the passage of water and can effectively seal water tanks, ensuring that they remain watertight. These membranes are commonly made from materials such as bitumen, PVC, or EPDM, which provide excellent resistance to water and are capable of withstanding the harsh conditions often found in water tanks. Additionally, waterproofing membranes can be applied to various surfaces, including concrete, metal, and masonry, making them versatile and suitable for different types of water tanks. Overall, using a waterproofing membrane is a reliable solution for ensuring the integrity and longevity of water tanks by preventing water leakage and protecting the surrounding environment from potential water damage.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels or flooding?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels or flooding. Waterproofing membranes are designed to provide a barrier against water penetration, making them suitable for such conditions. They can effectively protect structures from water damage and prevent moisture infiltration, even in areas with high water tables or frequent flooding.

Send your message to us

sbs app modified bitumen waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords