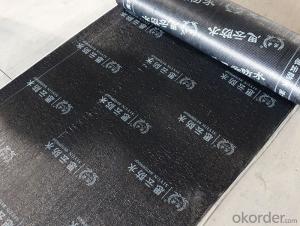

SBS/APP modified bitumen waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is

made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO,

APO), reinforced with polyester or fiberglass, finishing the upward face with polythene

membrane, fine sands or mineral slates (or grains) or etc.

2. Specification

1) Thickness: 3mm, 4mm, 5mm

2) Size: 1m (width)*10m (length) or on demand

3) Base: Polyester felt

4) Surface: PE film, Aluminum foil, Yellow sand, Shale gravel (Schist), Colored sand

5) Self adhesive type

Thickness: 1.2mm, 1.5mm, 2mm, 3mm, 4mm;

With or without polyester felt

Surface: PE film, Aluminium foil, Double-sided adhesive

6) SBS modified bitumen membrane is specially applied in the cold district,

APP modified bitumen membrane is more suitable for hot district with high temperature.

7) Certificate: ISO9001/14001

3. Applications

1) Roof and underground in industrial and civil buildings;

2) Bridge, subway, tunnel, swimming pool, etc.

3) Waste landfill, sewage plant, irrigation system, etc.

- Q: Can a waterproofing membrane be used in government or municipal projects?

- Absolutely, government or municipal projects can most certainly utilize a waterproofing membrane. It is, in fact, a vital element frequently employed in the construction or refurbishment of diverse infrastructure projects like roads, bridges, tunnels, and buildings. The purpose of waterproofing membranes is to thwart water infiltration, which may inflict harm upon the structure and undermine its stability. By incorporating a waterproofing membrane, government and municipal projects can guarantee the endurance and robustness of their infrastructure, thereby diminishing the necessity for costly repairs or replacements in the future. Furthermore, these membranes also contribute to energy efficiency by preventing moisture intrusion, thereby reducing the potential for mold growth and enhancing insulation properties. All in all, it is highly recommended to integrate a waterproofing membrane in government or municipal projects to elevate the lifespan and functionality of the infrastructure.

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Yes, a waterproofing membrane can be used in areas with high levels of salt or saltwater exposure. However, it is important to choose a membrane specifically designed to withstand such conditions. Certain waterproofing membranes are specifically formulated to be resistant to salt and saltwater exposure, preventing any potential damage or degradation. These membranes are typically made with materials that are highly resistant to corrosion and have enhanced durability. It is crucial to consult with a professional to ensure the correct type of waterproofing membrane is selected for high salt or saltwater exposure areas to ensure long-term effectiveness and protection.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Yes, there are some drawbacks and limitations to using a waterproofing membrane. One limitation is that the installation process can be time-consuming and labor-intensive. Waterproofing membranes often require careful surface preparation and multiple layers, which can be time-consuming and may require skilled labor. This can increase the overall cost of the project. Another limitation is that waterproofing membranes may not be suitable for all surfaces. Some membranes are designed specifically for certain types of substrates, such as concrete or metal, and may not adhere properly to other materials. It is important to select the appropriate type of membrane for the specific surface to ensure proper adhesion and effectiveness. Additionally, waterproofing membranes can be sensitive to environmental conditions. Extreme temperature fluctuations, UV exposure, and chemical exposure can degrade the membrane over time, reducing its effectiveness. Regular inspections and maintenance may be required to ensure the longevity of the membrane. Furthermore, waterproofing membranes can be susceptible to damage during installation or from external factors such as foot traffic or heavy objects. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, waterproofing membranes may not completely prevent water penetration in certain situations. For example, if there are existing cracks or structural issues in the substrate, water may still find a way to seep through, bypassing the membrane. It is important to address any underlying structural issues before applying the membrane to ensure optimal performance. Overall, while waterproofing membranes offer many benefits in terms of protecting against water damage, it is crucial to consider these limitations and drawbacks to make an informed decision about their use in specific applications.

- Q: Is a waterproofing membrane resistant to chemicals?

- Yes, a waterproofing membrane is typically resistant to chemicals. Waterproofing membranes are designed to provide a protective barrier against water and other liquids, including chemicals. These membranes are made of materials that are chemically resistant, such as PVC (polyvinyl chloride), TPO (thermoplastic olefin), or EPDM (ethylene propylene diene monomer). These materials have excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. Additionally, waterproofing membranes undergo rigorous testing to ensure their chemical resistance and durability. However, it is important to note that the specific chemical resistance may vary depending on the type and quality of the membrane. It is always recommended to consult the manufacturer's specifications and guidelines to ensure the membrane's compatibility with specific chemicals.

- Q: Does a waterproofing membrane require any maintenance or regular inspections?

- Indeed, the maintenance and regular inspection of a waterproofing membrane are necessary. Although these membranes are built to be robust and have a prolonged lifespan, they are still susceptible to the effects of wear and tear and potential harm. Consistent inspections are crucial in order to detect any indications of damage or deterioration promptly, allowing for swift action to prevent further complications. Maintenance tasks may comprise the cleaning of the membrane to eliminate dirt or debris, mending any visible cracks or tears, and guaranteeing appropriate drainage and water flow. Furthermore, it is advisable to adhere to the manufacturer's maintenance guidelines and arrange professional inspections periodically to ensure the waterproofing membrane's efficacy and longevity.

- Q: Can a waterproofing membrane be used on concrete slabs or foundations?

- Yes, a waterproofing membrane can be used on concrete slabs or foundations. It serves as a protective barrier against water penetration, preventing moisture-related issues such as leaks, mold, and structural damage. The membrane is typically applied to the exterior surface of the concrete to create a waterproof seal.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can be used in schools or educational buildings. Waterproofing membranes are commonly used in these types of buildings to protect them from water damage and leakage. By preventing water infiltration, a waterproofing membrane helps maintain a safe and healthy environment for students and staff, preserving the structural integrity of the building and reducing maintenance costs in the long run.

- Q: Can a waterproofing membrane be used on tunnels with water drainage systems?

- Yes, a waterproofing membrane can be used on tunnels with water drainage systems. The membrane acts as a barrier, preventing water from penetrating the tunnel structure and directing it towards the drainage system for proper disposal. This helps to ensure the integrity and longevity of the tunnel while effectively managing water flow.

- Q: Are waterproofing membranes resistant to root penetration?

- Yes, waterproofing membranes are generally resistant to root penetration. These membranes are specifically designed to prevent water from penetrating through the surface and into the underlying structure. In addition to their water resistance, they also possess qualities that make them resistant to root penetration. This is important in areas where vegetation or trees may be present, as roots have the potential to grow and penetrate through various surfaces, causing damage and compromising the integrity of the waterproofing system. Waterproofing membranes are typically made from materials that are tough and durable, providing a barrier that roots cannot easily penetrate. However, it is important to note that no waterproofing membrane is completely immune to root penetration, as some root systems may be particularly aggressive or invasive. In these cases, additional measures such as root barriers or specialized membranes may be necessary to ensure long-term protection against root penetration.

- Q: Can a waterproofing membrane be used on tunnels with lighting systems?

- Yes, a waterproofing membrane can be used on tunnels with lighting systems. In fact, it is often necessary to use waterproofing membranes in tunnels to protect the structure from water infiltration. These membranes are designed to create a barrier that prevents water from seeping into the tunnel and causing damage. They are typically applied to the tunnel walls, floors, and ceilings and can be used in conjunction with lighting systems without any issues. The waterproofing membrane will not affect the functionality or safety of the lighting system and will help ensure that the tunnel remains watertight and protected from moisture-related issues.

Send your message to us

SBS/APP modified bitumen waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords