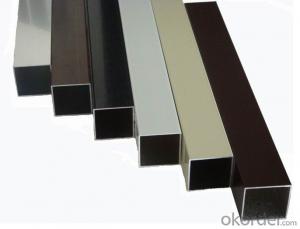

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

anodized aluminum square tube

1.Alloy 2014 2024 7020 6061 7075

2.Temper:F O T4 T5 ,T6

3.Out diameter:4.5-610 mm

Product name | anodized aluminum square tube | |

Shape | Round, oval, square, rectangle | |

Size | Out Diameter | 4.5-610 mm |

Wall Thickness | 1-110 mm | |

Length | According to customer’s requirement | |

Alloy | 1070-1100 3003 5052 5754 5083 5056 2017 2014 2A12 2024 6060 6082 6061 6063 7050 7075 7005 7020 7A09 | |

Temper | F, O, T4, T5, T6 | |

Standard | GB /ASTM | |

Surface Treatment | 1.mill finished 2.anodizing:shiny anodized,frosty anodized 3.electrophoretic coating:shiny elecyrophoretic,frosty electrophoretic 4.electrophoretic color powder coating:normal color,special color. 5.fluorocarbon powder spraying:normal color,special paper 6.polished 7.wood grain coating: special paper, special paper

| |

Application | Construction, decoration and industry | |

Origin | Chongqing ,China | |

Port | Chongqing or Shanghai | |

MOQ | 2 Metric Tons | |

Delivery Time | 30 work days after deposit or L/C | |

Payment Terms | T/T, irrevocable L/C at sight. | |

Supply Ability | 5000 Metric Ton / Month | |

Packaging | Foam paper and carton box package,kraft paper package,plastic film and the plastic wrap package are optional,or as requested. | |

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: Are aluminum profiles suitable for use in the electronics industry?

- The electronics industry finds aluminum profiles to be a suitable option. Aluminum, being lightweight, durable, and resistant to corrosion, becomes an excellent choice for different electronic applications. Its exceptional thermal conductivity facilitates efficient dissipation of heat in electronic devices, which is crucial to avoid overheating and ensure optimal performance. Moreover, aluminum profiles can be easily customized and fabricated to fulfill specific design requirements, making them adaptable for various electronic components and enclosures. They also possess electromagnetic shielding properties, safeguarding sensitive electronic circuits from interference. All in all, aluminum profiles provide numerous advantages for the electronics industry, making them a popular and appropriate option for electronic devices and equipment.

- Q: This question asks for methods to ensure the reliable and durable installation of aluminum profiles.

- <p>To ensure the reliable and durable installation of aluminum profiles, follow these steps: Use high-quality aluminum materials that meet industry standards for strength and durability. Ensure proper alignment and level during installation to prevent warping or stress on the profiles. Use appropriate fasteners and adhesives recommended for aluminum to ensure a strong bond. Avoid over-tightening fasteners, which can cause deformation. Regularly inspect and maintain the profiles to check for signs of wear or damage, and address any issues promptly. This will help maintain the integrity and longevity of the aluminum profiles.</p>

- Q: 80 series insulation aluminum broken bridge 1.4 thick, one square kilogram, how many kilograms aluminum material?

- Each brand of profiles, aluminum weight is not the same, but within the unit area is about 8 kilograms, little difference

- Q: Can Linqu aluminum profile factory have 100 home?

- Two hundred or three hundred also have.AskIn addition to a set of near east outer ring and other small scale enterprises, which are located in theChasing the answerEast of the ring, the prosperous road is the axis, and the two sides are basically on both sides.

- Q: Are aluminum profiles suitable for use in architectural lighting fixtures?

- <p>Yes, aluminum profiles are commonly used for architectural lighting fixtures due to their durability, lightweight nature, and excellent heat dissipation properties. They offer design flexibility and can be easily shaped and machined to fit various lighting designs. Additionally, aluminum's resistance to corrosion makes it ideal for both indoor and outdoor lighting applications.</p>

- Q: Can aluminum profiles be used in modular exhibition system manufacturing?

- Yes, aluminum profiles can be used in modular exhibition system manufacturing. Aluminum profiles are known for their lightweight and durable properties, making them ideal for constructing modular exhibition systems. They are easy to handle and assemble, allowing for quick and efficient installation and dismantling of exhibition booths. Additionally, aluminum profiles can be easily customized and reconfigured to meet specific design requirements, making them a versatile choice for modular exhibition system manufacturing.

- Q: Is it possible to use aluminum profiles for outdoor applications like fences and railings?

- <p>Yes, aluminum profiles are commonly used for outdoor applications such as fences and railings. They are favored for their resistance to corrosion, lightweight properties, and durability. Aluminum can withstand harsh weather conditions without rusting, making it an ideal material for outdoor use. Additionally, it is low maintenance, as it does not require painting or frequent repairs. The profiles can be powder-coated or anodized for enhanced protection and aesthetic appeal.</p>

- Q: This question asks about the various types of aluminum profiles that are specifically used in roof insulation systems.

- <p>Aluminum profiles for roof insulation systems are designed to provide structural support and thermal insulation. Common types include: 1) U-channels, which are used as support beams; 2) C-profiles, used for connecting and securing insulation boards; 3) H-profiles, serving as main rafters or purlins; 4) Z-profiles, often used as secondary rafters or for sealing; 5) T-profiles, used for creating airtight seals at the edges; and 6) L-profiles, which can be used for corner reinforcements. These profiles come in various sizes and thicknesses to suit different roofing specifications and insulation requirements.</p>

- Q: Can aluminum profiles be used in the construction of playground equipment?

- Yes, aluminum profiles can be used in the construction of playground equipment. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for outdoor applications such as playground equipment. It offers strength and stability while being easy to work with, allowing for the creation of various structures and designs. Additionally, aluminum profiles can be customized to meet specific requirements, ensuring the safety and functionality of the playground equipment. Overall, the use of aluminum profiles in playground equipment construction provides a reliable and long-lasting solution.

Send your message to us

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords