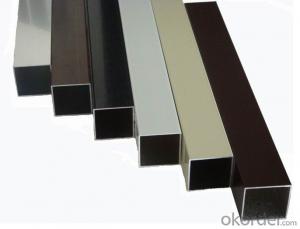

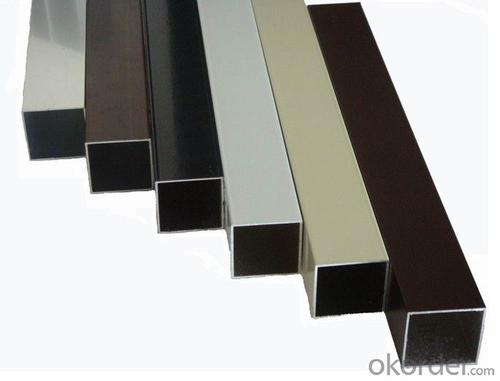

Mk Aluminum Profiles - Aluminium Square Tube Profile for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Aluminum Square Tubes

1: Extrusion tooling free!

2: Fast lead time!

3: Guaranteed quality!

Aluminum Square Tubes

Dongke Aluminum has many existing toolings, please do not hesitate to contact us. Our professional and very amenable Dongkers are at your service!

1-Chemical Composition Of Aluminum Alloy

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | 0.45-0.9 | <0.35 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.05 | < 0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.8-1.2 | <0.7 | 0.15-0.4 | < 0.15 | < 0.25 | 0.04-0.35 | < 0.15 | < 0.05 | < 0.15 | Surplus |

2- Chemical Properties Of Aluminum Alloy

| Alloy | Temper | Thickness | Intensity streching resistance 6b (Mpa) | Intensity of bending 6p0.2(Mpa) | Stretching rate | T of tested samples (mm) | HV | HW |

| ≥ | ||||||||

| 6063 | T5 | All | 160 | 110 | 8 | 0.8 | 58 | 8 |

| 6061 | T6 | All | 205 | 180 | 8 | 0.8 | 90 | 15 |

- Q: Can aluminum profiles be used for display cases or cabinets?

- Certainly, display cases or cabinets can make great use of aluminum profiles. These profiles are renowned for their lightweight nature, durability, and sleek, contemporary aesthetic, making them a favored option for showcasing products or housing belongings. Their versatility is further enhanced by the ease with which they can be personalized and their availability in various sizes and shapes to meet specific design needs. Moreover, these profiles possess exceptional resistance to corrosion, rendering them suitable for both indoor and outdoor applications. Additionally, their remarkable thermal conductivity can prove advantageous in regulating temperatures within display cases or cabinets. All in all, aluminum profiles offer a diverse and appealing solution for constructing display cases or cabinets.

- Q: How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- [60] galuminium Qianjin aluminum series insulating aluminum window size 60x53.5, window size 67.8x68.6.

- Q: Can aluminum profiles be used in display shelving and racking systems?

- Yes, aluminum profiles can be used in display shelving and racking systems. Aluminum profiles offer various benefits such as lightweight, durability, and versatility, making them suitable for these applications. They can be easily customized, assembled, and adjusted to meet specific shelving and racking requirements. Additionally, aluminum profiles provide an aesthetically pleasing and modern look to the display shelving and racking systems.

- Q: How do aluminum profiles contribute to sustainable packaging solutions?

- The eco-friendly properties of aluminum profiles are crucial in promoting sustainable packaging solutions. Firstly, aluminum is highly recyclable, and its profiles can be easily recycled without losing their inherent qualities. This enables a closed-loop recycling system, reducing the need for new raw materials and minimizing waste. In addition, aluminum profiles offer exceptional strength and durability, ensuring that packaging made from them can withstand rigorous handling and transportation. This durability reduces the likelihood of damage or breakage, resulting in less product waste and minimizing the need for additional packaging materials. Furthermore, aluminum profiles provide excellent barrier properties, protecting the contents of the packaging from external factors like moisture, oxygen, light, and temperature variations. This helps extend the shelf life of products, reducing food waste and ensuring that goods remain fresh and safe for consumption. Moreover, aluminum profiles are lightweight, contributing to energy savings during transportation. The lightweight nature of aluminum packaging allows for reduced fuel consumption and lower carbon emissions, making it an environmentally friendly choice. Lastly, aluminum profiles are resistant to corrosion, ensuring that the packaging remains intact and functional for an extended period. This longevity reduces the need for frequent replacement, saving resources and minimizing the overall environmental impact. In conclusion, aluminum profiles promote sustainable packaging solutions by being recyclable, durable, providing excellent barrier properties, lightweight, and corrosion-resistant. These properties help minimize waste, reduce energy consumption, extend product shelf life, and lower carbon emissions, making aluminum profiles an ideal choice for eco-conscious packaging solutions.

- Q: Can aluminum profiles be used in corrosive environments?

- Aluminum profiles can be used in corrosive environments, but it is important to consider certain factors before making a decision. Aluminum is naturally resistant to corrosion due to the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing further corrosion. However, in highly corrosive environments such as areas with high humidity, saltwater exposure, or acidic conditions, the protective oxide layer may deteriorate over time. To enhance the resistance of aluminum profiles in corrosive environments, various measures can be taken. One option is to choose an aluminum alloy with higher corrosion resistance, such as aluminum alloys with a higher percentage of alloying elements like copper or zinc. These alloys are often referred to as marine-grade or corrosion-resistant alloys. Additionally, surface treatments like anodizing or powder coating can further improve the corrosion resistance of aluminum profiles. Anodizing involves the formation of a thicker and more durable oxide layer on the surface of the aluminum, while powder coating provides an additional protective layer that acts as a barrier against corrosive agents. Regular maintenance and cleaning are also crucial for preserving the corrosion resistance of aluminum profiles in corrosive environments. This includes removing any accumulated dirt or debris that may contain corrosive substances. In summary, while aluminum profiles can be used in corrosive environments, it is essential to select the appropriate alloy, consider surface treatments, and perform regular maintenance to ensure their long-term performance and durability.

- Q: What are the top 20 Chinese architectural aluminum profiles?

- China's top twenty aluminum profiles enterprises:1, Guangdong Xingfa Aluminum Co. Ltd. Guangdong Feng Aluminum Co. Ltd. (TIE)2 、 Shandong Nanshan aluminum Limited by Share Ltd3, Guangdong Haomei Aluminum Co. Ltd.4 、 Nanping Fujian Aluminium Industry Co., Ltd.5, Guangdong Jianmei aluminum profile factory (Group) Co., Ltd.6 、 Guangdong Huachang aluminium factory Co., Ltd.

- Q: This question asks about the various types of aluminum profiles that are utilized in flooring systems, seeking to understand their specific applications and characteristics.

- <p>Aluminum profiles for flooring systems are designed for specific purposes and come in various types, including: 1. T-profiles, which are used as support beams for raised access floors; 2. L-profiles, often used for edge trims and transitions; 3. H-profiles, serving as main beams in the flooring structure; 4. U-channels, used for cover strips and edge protection; 5. C-profiles, which can be used for cable management within the floor void; 6. Z-profiles, suitable for joint covers and transitions. These profiles are chosen based on the load-bearing requirements, aesthetic considerations, and specific structural needs of the flooring system.</p>

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Warehouse and storage systems can utilize aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, which make them suitable for a variety of applications in warehouses and storage systems. They can be utilized for the construction of shelving units, racks, and partitions in order to optimize storage space and arrange inventory. Aluminum profiles are also highly versatile, allowing for easy customization and assembly to fulfill specific storage requirements. Furthermore, these profiles offer an exceptional strength-to-weight ratio, enabling them to support heavy loads without compromising the structural integrity. Overall, due to their durability, flexibility, and cost-effectiveness, aluminum profiles are widely preferred in warehouse and storage systems.

- Q: Are there any safety considerations when working with aluminum profiles?

- Working with aluminum profiles requires several safety considerations. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a dust mask. This is necessary because handling aluminum profiles can produce fine metal shavings and dust, which can be harmful if inhaled or come into contact with the skin or eyes. Moreover, ensuring proper ventilation in the work area is essential to reduce the accumulation of aluminum dust and fumes. This can be achieved by utilizing exhaust fans or opening windows and doors to allow fresh air circulation. When cutting or machining aluminum profiles, it is vital to use the correct tools and techniques to prevent accidents or injuries. This includes employing sharp blades or cutting tools specifically designed for aluminum to avoid kickback or other hazards. Additionally, careful handling of aluminum profiles is important as they may have sharp edges or corners that can cause cuts or injuries. It is crucial to use proper lifting techniques to prevent strain or back injuries when moving or installing aluminum profiles. Lastly, being aware of the potential fire hazards associated with aluminum dust is crucial. Aluminum dust is highly flammable and can ignite when exposed to an ignition source like a spark or open flame. Therefore, maintaining a clean work area and regularly removing any accumulated aluminum dust is necessary to minimize the risk of fire. By adhering to these safety considerations and taking necessary precautions, the risks associated with working with aluminum profiles can be minimized, ensuring a safe working environment.

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Mk Aluminum Profiles - Aluminium Square Tube Profile for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords