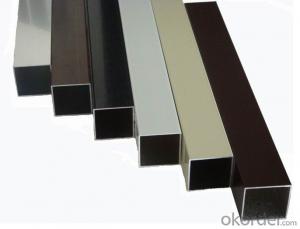

T-Slotted Structural Aluminum Profiles - Coated Aluminum Square Tubes for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name:aluminum tube&aluminum pipe

Material | 1000series,2000series,3000series.... |

Temper | T4,T5,T6 |

ISO Certificate | ISO9001:2008,SGS |

Size | The size are available in accordance with customers' options. |

Mill finish, Powder Coating, Anodizing, Sandblasting Anodizing, | |

Surface Processing | Cataphoresis, Sandblasting Cataphoresis, Wooden Print etc. |

Shape | round pipe |

Use | Building,Machine,Decoration,etc |

Color | Silver,Golden,Black,Red,Blue a,etc |

Packing: | Export sea worthy package |

Delivery: | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ: | 1 Metric Ton/Metric Tons |

Price terms: | FOB, CFR, CIF |

Payment terms: | T/T, L/C |

Application | aluminum pipe applies to Structural use ,roofing, commercial use, household appliance, industry, family etc |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

- Q: Can aluminum profiles be used in the production of agricultural equipment?

- Yes, aluminum profiles can be used in the production of agricultural equipment. Aluminum is a versatile and lightweight material that offers several advantages for agricultural applications. It is corrosion-resistant, which is essential for equipment exposed to outdoor conditions and various chemicals used in farming. Additionally, aluminum profiles can be easily shaped and customized to fit specific design requirements, allowing for the creation of complex and functional agricultural equipment. The lightweight nature of aluminum also makes it easier to transport and handle the equipment, reducing labor costs. Moreover, aluminum profiles are recyclable, making them an environmentally friendly choice for agricultural equipment production. Overall, utilizing aluminum profiles in agricultural equipment can enhance durability, efficiency, and sustainability in the farming industry.

- Q: This question asks about the strength and suitability of aluminum profiles for outdoor applications.

- <p>Yes, aluminum profiles are strong enough for exterior use. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum profiles can withstand various weather conditions and maintain their strength over time. They are also low-maintenance, as they do not rust or rot, and can be easily cleaned. Additionally, aluminum profiles can be anodized or powder-coated for enhanced durability and resistance to UV rays, further ensuring their suitability for exterior use.</p>

- Q: What are the different types of aluminum alloys used for profiles?

- There are several different types of aluminum alloys that are commonly used for profiles. Some of the most common types include: 1. 6061 Aluminum Alloy: This alloy is one of the most versatile and widely used aluminum alloys. It offers a good combination of strength, weldability, and corrosion resistance. It is commonly used in structural applications and for making frames, railings, and automotive parts. 2. 6063 Aluminum Alloy: This alloy is known for its excellent formability and extrudability, making it ideal for producing profiles. It offers good corrosion resistance and can be easily shaped into complex designs. It is commonly used for architectural applications, such as window frames, door frames, and curtain walls. 3. 7075 Aluminum Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue strength. It is commonly used in aerospace applications and for making high-performance products such as bicycle frames and sporting goods. 4. 5083 Aluminum Alloy: This alloy is primarily used in marine applications due to its excellent corrosion resistance in saltwater environments. It is commonly used for boat hulls, decks, and other marine structures. 5. 3003 Aluminum Alloy: This alloy is known for its good formability, corrosion resistance, and weldability. It is commonly used in general-purpose applications, such as signage, electrical enclosures, and kitchenware. These are just a few examples of the different types of aluminum alloys used for profiles. The selection of the alloy depends on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost.

- Q: 5002 and 6063 aluminum profiles difference

- 6063 aluminum alloy main alloy elements for magnesium and silicon, with excellent processability, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy polishing, coating, anode oxidation effect is excellentIt is a typical extrusion alloy, widely used in building profiles, irrigation pipes, tubes, rods and profiles for vehicles, platforms, furniture, elevators, fences, etc.

- Q: Top 10 ranking enterprises of aluminum profiles in China

- Don't just look at rankings, which is something false, we all know in the aluminum industry, aluminum extrusion and some more than 50 units, annual production capacity of 90 thousand tons, were stronger than some ten enterprises inside the above you can see, but in the rankings but no, this ranking is water.

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Working with aluminum profiles requires specific safety precautions that should be considered. Here are some important precautions to keep in mind: 1. Personal Protective Equipment (PPE): It is vital to wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to safeguard against potential injuries. Aluminum chips or shavings can cause cuts or abrasions. 2. Ventilation: Ensure that the working area has proper ventilation to prevent the accumulation of aluminum dust or fumes. Aluminum dust can be combustible, and inhaling aluminum fumes can result in respiratory problems. 3. Fire Safety: Due to its high flammability, it is crucial to have fire prevention measures in place. Keep a fire extinguisher nearby and avoid sparks or open flames near aluminum profiles. Choose non-sparking tools and be cautious of excessive heat during cutting or welding processes. 4. Handling and Storage: Aluminum profiles can be heavy, so it is important to use correct lifting techniques to avoid back or muscle injuries. Store aluminum profiles securely and in an organized manner to minimize the risk of tripping or falling. 5. Cutting and Machining: When cutting or machining aluminum profiles, use appropriate tools and techniques. Ensure that the material is securely clamped before any cutting operation to prevent movement and potential accidents. 6. Ergonomics: Prioritize maintaining good ergonomics while working with aluminum profiles to reduce the risk of repetitive strain injuries or musculoskeletal disorders. Utilize ergonomic tools or equipment to minimize strain on the body. 7. Training and Knowledge: It is essential to undergo proper training and acquire knowledge about working with aluminum profiles. Understand the specific properties of aluminum and the associated hazards to work safely and efficiently. By adhering to these safety precautions, the risk of accidents, injuries, or health hazards when working with aluminum profiles can be significantly reduced.

- Q: What are the bending capabilities of aluminum profiles?

- Aluminum profiles have excellent bending capabilities due to their malleability and ductility. They can be easily formed into various shapes and angles, making them versatile for a wide range of applications. However, the specific bending capabilities may vary depending on the alloy and temper of the aluminum profile.

- Q: Can aluminum be utilized as a material for constructing railings and fences?

- <p>Yes, aluminum profiles are commonly used for railings and fences due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be powder-coated in various colors to match architectural styles. Aluminum railings and fences are also appreciated for their strength and ability to withstand harsh weather conditions without rusting or rotting, making them a popular choice for both residential and commercial applications.</p>

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent fire-resistant properties due to their high melting point of about 660 degrees Celsius (1220 degrees Fahrenheit). Additionally, aluminum forms a protective oxide layer when exposed to heat, which further enhances its resistance to fire. This oxide layer acts as a barrier, preventing oxygen from reaching the aluminum surface and inhibiting the combustion process. As a result, aluminum profiles are widely used in various applications where fire safety is crucial, such as building construction and transportation industries.

- Q: What are the different types of protective coatings for aluminum profiles?

- There exists a variety of protective coatings for aluminum profiles that serve to enhance their durability and lifespan, as well as add aesthetic appeal. Some common types include: 1. Anodizing: This popular and widely used coating involves an electrochemical process that generates a thin, transparent layer of aluminum oxide on the metal's surface. It provides exceptional corrosion resistance and can be customized with various dye colors. 2. Powder Coating: In this dry finishing process, an electrostatically charged powder is applied onto the aluminum surface, then heated to create a durable and protective coating. Powder coating offers excellent resistance to impact, chemicals, and corrosion, while also providing a uniform and attractive finish. 3. Paint Coating: Aluminum profiles often utilize paint coatings, particularly in applications where aesthetics are crucial. These coatings can be applied through spraying, brushing, or dipping methods, offering protection against corrosion, UV rays, and other environmental factors. They also offer a wide range of color options. 4. E-Coating: Also known as electrocoating or electrophoretic deposition, this immersion-based process involves submerging the aluminum profiles in a water-based paint solution and applying an electric current. This results in a uniform and protective coating, often used as a primer before applying other coatings. E-coating excels in corrosion resistance. 5. Clear Coating: Transparent protective layers, such as clear lacquers or clear anodizing, are frequently employed to preserve the natural appearance of aluminum profiles while shielding them against corrosion and environmental factors. Choosing the appropriate protective coating for your aluminum profiles necessitates considering specific requirements and the intended application. Factors such as durability, corrosion resistance, aesthetics, and cost should be taken into account to ensure the optimal choice for your particular needs.

Send your message to us

T-Slotted Structural Aluminum Profiles - Coated Aluminum Square Tubes for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords