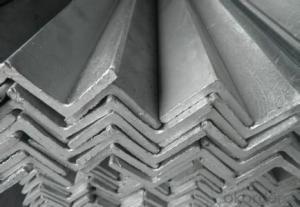

Angle Steel Hot Rolled ASTM A36 and GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1 What makes stainless steel stainless?

A1 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel angles be used for manufacturing balcony structures?

- Yes, steel angles can be used for manufacturing balcony structures. Steel angles provide structural support and stability to balcony structures, making them a suitable choice for their construction.

- Q: How do steel angles contribute to the overall stability of a structure?

- The overall stability of a structure is significantly influenced by steel angles, which serve multiple purposes. Primarily, steel angles are widely used as structural members in various applications, including building frames, bridges, and towers. Their L-shaped profile offers exceptional strength and load-bearing capabilities, making them ideal for supporting heavy loads and resisting bending or buckling. An important role of steel angles is to provide structural support and stability by distributing the load evenly across different components of the structure. By connecting elements like beams, columns, and girders, steel angles effectively transfer and resist weight and forces acting on the structure, thereby preventing potential collapse or failure. Furthermore, the overall rigidity and stiffness of a structure are enhanced by steel angles. When diagonal bracing elements made of steel angles are added, the structure becomes more resistant to lateral forces such as wind or earthquakes. These diagonal braces create a stable triangular configuration capable of withstanding horizontal loads. Consequently, the increased stability and resistance to lateral forces greatly contribute to the overall safety and durability of the structure. In addition, steel angles play a crucial role in mitigating torsional forces in a structure. Torsion occurs when one end of a structural member is twisted while the other end remains fixed, resulting in a twisting moment being applied to the structure. To counteract these torsional forces, steel angles can be strategically placed and connected, preventing excessive twisting or deformation that could jeopardize the structure's stability. To summarize, steel angles are vital components that contribute to the overall stability of a structure through various means. They offer structural support, efficiently distribute loads, enhance rigidity, resist lateral forces, and mitigate torsional forces. By incorporating steel angles into the design and construction of a structure, engineers can ensure its long-term stability, safety, and durability.

- Q: Are steel angles suitable for architectural applications?

- Yes, steel angles are suitable for architectural applications. Steel angles are often used in construction and architectural projects for their versatility, strength, and aesthetic appeal. They can be used to create structural frames, supports, and connections, as well as for decorative purposes. Steel angles come in a variety of sizes, thicknesses, and finishes, allowing architects to choose the most suitable option for their specific design requirements. Additionally, steel angles can be easily welded, drilled, and manipulated to fit different angles and shapes, making them a versatile and cost-effective choice for architectural applications.

- Q: How do steel angles contribute to the overall aesthetic of a structure?

- There are numerous ways in which steel angles can enhance the overall aesthetic of a structure. Firstly, their sleek and tidy lines can bring a modern and contemporary touch to the design. The sharp edges and precise angles of steel angles can generate a feeling of strength and solidity, resulting in a bold and industrial atmosphere for the structure. Furthermore, steel angles offer the opportunity to create captivating and dynamic shapes within the architecture. Their versatility allows for the development of unique and attention-grabbing designs, such as cantilevered balconies or intricate lattice patterns. These visually pleasing features can become focal points of the structure, enhancing its overall aesthetic appeal. In addition, steel angles can be utilized to establish a sense of rhythm and repetition in the design. By incorporating them in a consistent pattern or arrangement, they can create a visual harmony and balance. This repetition can be particularly effective in large-scale structures, where the steel angles can break up the monotony of the façade and add visual interest. Moreover, steel angles contribute to the durability and longevity of the structure, which, in turn, enhances its aesthetic value. Steel is renowned for its strength and resilience, and when used in angles, it provides structural support and stability. This durability ensures that the structure remains visually appealing for many years without compromising on safety or integrity. Overall, steel angles play a significant role in the aesthetic of a structure, adding a sense of modernity, strength, and versatility. Their clean lines, dynamic shapes, and durability all contribute to creating a visually appealing and impactful architectural design.

- Q: What is the difference between galvanized steel bar and ordinary angle iron?

- Durable: galvanized steel with surface gloss, zinc layer uniform, no plating leakage, without drip, strong adhesion characteristics, strong corrosion resistance, in a suburban environment, galvanized thickness standard can be maintained for more than 50 years without repair; in urban areas or coastal areas, the standard hot galvanized layer it can be maintained for 20 years without repair;

- Q: Are steel angles available in different alloys?

- Different alloys are available for steel angles, providing a wide range of options. Typically, steel angles are made from carbon steel, which is a versatile and common type of steel. However, specific applications may call for other alloys. For instance, stainless steel angles are made from an alloy containing chromium, offering increased resistance to corrosion. In addition, high-strength low-alloy (HSLA) steel angles combine carbon steel with small amounts of elements like manganese, phosphorus, or sulfur to enhance strength and durability. This variety of alloys allows for a diverse range of applications and properties to meet specific needs across various industries.

- Q: Are steel angles suitable for mezzanine floor construction?

- Yes, steel angles are suitable for mezzanine floor construction. Steel angles provide structural support and stability, making them a popular choice for building mezzanine floors. They are strong, durable, and can withstand heavy loads, making them an ideal choice for creating additional floor space in industrial or commercial settings.

- Q: What are the tolerances for steel angles?

- The tolerances for steel angles may differ based on the particular grade and manufacturing standards. Nevertheless, typical tolerances for steel angles commonly encompass dimensional tolerances like length, width, and thickness. These tolerances guarantee that the steel angles meet the necessary specifications and can be effectively employed in diverse applications. Concerning length, the tolerance usually spans from ±1/8" to ±1/4", contingent upon the angle's size and grade. This signifies that the actual length of the angle can fluctuate within this range from the specified length. Likewise, for width, the tolerance can vary from ±1/8" to ±1/4", ensuring that the actual width of the angle falls within this range from the specified width. Regarding thickness, the tolerance can differ depending on the manufacturing process and the grade of the steel angle. However, customary tolerances for thickness may range from ±1/16" to ±1/8". This tolerance guarantees that the actual thickness of the angle is within this range from the specified thickness. It is crucial to note that these tolerances serve as general guidelines and may vary based on the specific requirements and standards established by manufacturers or industry regulations. Therefore, it is always advisable to refer to the product specifications or consult the manufacturer for accurate and up-to-date information on tolerances for steel angles.

- Q: What are the standard tolerances for steel angles?

- The tolerances for steel angles can vary depending on the angle's specific grade and size. Generally, dimensional tolerances and straightness tolerances are included in the standard tolerances for steel angles. Dimensional tolerances pertain to the allowable variations in the angle's dimensions, including thickness, width, and length. These tolerances are usually expressed as a range or the maximum allowable deviation from the specified dimensions. On the other hand, straightness tolerances deal with the permissible deviation from a straight line that the angle can have. This is typically assessed by placing a straight edge along the angle's length and measuring the maximum gap between the straight edge and the angle. It is important to highlight that the appropriate tolerances for steel angles should be determined based on relevant standards and specifications provided by industry organizations or regulatory bodies. These standards and specifications will offer the necessary guidance on the acceptable tolerances for steel angles based on their intended use and application.

- Q: What are the different methods of reinforcing steel angles?

- Reinforcing steel angles can be strengthened in various ways, each with its own benefits and uses. One popular technique involves adding extra steel plates or brackets, which are typically welded or bolted onto the existing angle. This provides added support and strength, making it ideal for situations where the angle is subjected to heavy loads or stress. Another method involves using stiffeners, which are smaller steel angles or plates that are welded perpendicular to the existing angle. These stiffeners help to evenly distribute the load, preventing the angle from buckling or bending under pressure. This method is commonly employed when the angle serves as a structural member, such as in building frames or bridge supports. Furthermore, reinforcing steel angles can be achieved by encasing them in concrete or combining them with composite materials. In this approach, the steel angle is embedded within a concrete matrix or mixed with materials like fiberglass or carbon fiber. This combination enhances strength, durability, and resistance to corrosion. It is often employed in construction projects where the angle is exposed to harsh environments or requires superior performance. In summary, the various methods available for reinforcing steel angles offer choices for increasing their strength, stability, and longevity. The selection of a particular method depends on factors like the specific application, load requirements, and environmental conditions.

Send your message to us

Angle Steel Hot Rolled ASTM A36 and GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords