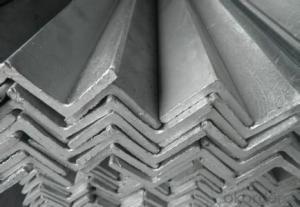

Angle Steel High Quality Hot Rolled Q235 OR ASTM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Angle Steel High Quality Hot Rolled Q235 OR ASTM A36 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Angle Steel High Quality Hot Rolled Q235 OR ASTM A36 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

、60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel angles be used for transportation infrastructure projects?

- Indeed, transportation infrastructure projects can make use of steel angles. The construction industry frequently relies on steel angles for a range of purposes, including the development of bridges, highways, and railways. These angles offer vital support and stability to such structures, ensuring their strength and durability. Their versatility allows for easy fabrication and installation, making them an excellent selection for transportation infrastructure projects that prioritize strength and dependability. Moreover, steel angles possess a remarkable load-bearing capacity and resistance to environmental elements, guaranteeing the long-term safety and longevity of transportation infrastructure. As a result, steel angles find extensive use in transportation infrastructure projects across the globe.

- Q: Are steel angles fire resistant?

- Steel angles are commonly regarded as fire resistant. This is because steel is a material that does not burn and can withstand high temperatures. Steel angles, which are L-shaped structural components, are widely used in construction and engineering due to their strength and durability. In the event of a fire, steel angles remain structurally intact and do not deform, which is crucial for the safety of a building or structure. However, it is important to consider that the fire resistance of steel angles may be influenced by various factors such as size, thickness, fire protection measures, and the duration and intensity of the fire. To enhance the fire resistance of steel angles and improve overall fire safety, measures like fire-resistant coatings, fire barriers, and fireproofing materials can be employed.

- Q: Can steel angles be used for framing in modular construction?

- Framing in modular construction can indeed utilize steel angles. These structural elements are widely employed in construction owing to their remarkable strength and versatility. Combining them through simple bolting or welding techniques allows for the creation of a robust framework, enhancing the overall stability and structural integrity of modular construction. Furthermore, steel angles exhibit exceptional durability and corrosion resistance, rendering them suitable for various environmental conditions. All in all, when it comes to framing in modular construction projects, steel angles prove to be a fitting selection.

- Q: What material is angle iron?

- The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components.

- Q: Can steel angles be used for support structures in telecommunications installations?

- Yes, steel angles can be used for support structures in telecommunications installations. Steel angles provide strength, stability, and durability, making them suitable for supporting heavy equipment such as antennas, cables, and other telecommunications infrastructure.

- Q: How do you clean and maintain steel angles?

- To ensure the cleanliness and maintenance of steel angles, a few essential materials and some simple steps are required. The following guide will assist you in carrying out the process: 1. Collect the necessary materials: You will require a soft cloth or sponge, mild detergent or soap, warm water, a bucket, and a microfiber cloth or towel for drying. 2. Begin by preparing a cleaning solution: Combine a small amount of mild detergent or soap with warm water in a bucket. Harsh chemicals or abrasive cleaners should be avoided, as they can harm the steel surface. 3. Immerse the soft cloth or sponge into the cleaning solution and squeeze out any excess liquid. It is important for the cloth to be damp, not saturated. 4. Delicately wipe the steel angles with the damp cloth or sponge. Ensure that you cover the entire surface, including the crevices and corners. In the case of stubborn stains or dirt, apply slightly more pressure, but avoid scrubbing too vigorously to prevent scratches. 5. Rinse the cloth or sponge with clean water and eliminate any soap residue from the steel angles. 6. Once the cleaning process is complete, use a microfiber cloth or towel to thoroughly dry the steel angles. This step is crucial to prevent the formation of water spots or rust. 7. For regular maintenance, a stainless steel cleaner or polish can be utilized. Apply a small amount of the cleaner onto a clean cloth and gently rub it onto the steel angles, following the instructions provided by the manufacturer. This will aid in restoring shine and safeguarding the steel surface. 8. Refrain from using abrasive materials such as steel wool or scouring pads, as they can cause scratches on the steel angles. Moreover, keep acidic substances or chemicals away from the steel, as they can induce corrosion. 9. It is also advisable to periodically inspect the steel angles for any indications of rust or damage. If any rust spots are noticed, a rust remover or stainless steel cleaner specifically designed for rust removal can be used. Carefully follow the instructions provided by the product and ensure that the angles are thoroughly dried afterwards. By adhering to these steps, you can effectively clean and maintain steel angles, ensuring their excellent condition for years to come.

- Q: What is the typical hardness of steel angles?

- The typical hardness of steel angles can vary depending on the specific grade and manufacturing process, but it is generally within the range of 150 to 200 Brinell Hardness Number (BHN).

- Q: What is the typical length of a steel angle?

- Steel angles can have varying lengths depending on their purpose and application. Generally, a steel angle is commonly found at a length of 20 feet or 6 meters. This standard length facilitates convenient handling, transportation, and installation in diverse construction and fabrication projects. Nevertheless, it is important to acknowledge that steel angles can be tailored or trimmed to shorter lengths in order to meet specific requirements or accommodate specific designs.

- Q: Can steel angles be used for structural purposes?

- Yes, steel angles can be used for structural purposes. Steel angles are commonly used in construction and engineering projects to provide structural support and stability. They are often used to reinforce and strengthen various structural components such as beams, columns, frames, and trusses. Steel angles are known for their high strength and durability, making them suitable for withstanding heavy loads and forces. They are versatile and can be easily welded, bolted, or screwed into place, allowing for easy installation and adaptation to different design requirements. Additionally, steel angles are available in various sizes, lengths, and thicknesses, making them suitable for a wide range of structural applications.

- Q: How are steel angles used in framing?

- Steel angles are commonly used in framing to provide structural support and stability. They are typically used to connect and reinforce various components of a frame, such as beams, columns, and trusses. Steel angles are often bolted or welded at specific locations to create a rigid framework that can withstand loads and distribute them evenly. This helps ensure the overall strength and integrity of the framed structure.

Send your message to us

Angle Steel High Quality Hot Rolled Q235 OR ASTM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords