Aluminum T Slot Extrusion Profiles for Cars - High Quality Auto-Parts Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile for Cars Auto-parts Good Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Cars Auto-parts Good Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

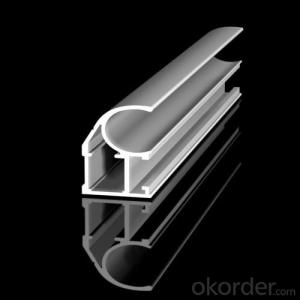

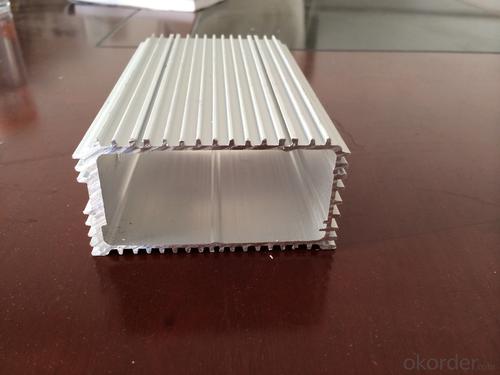

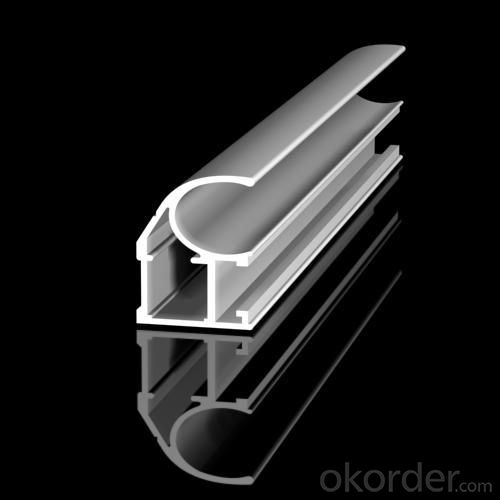

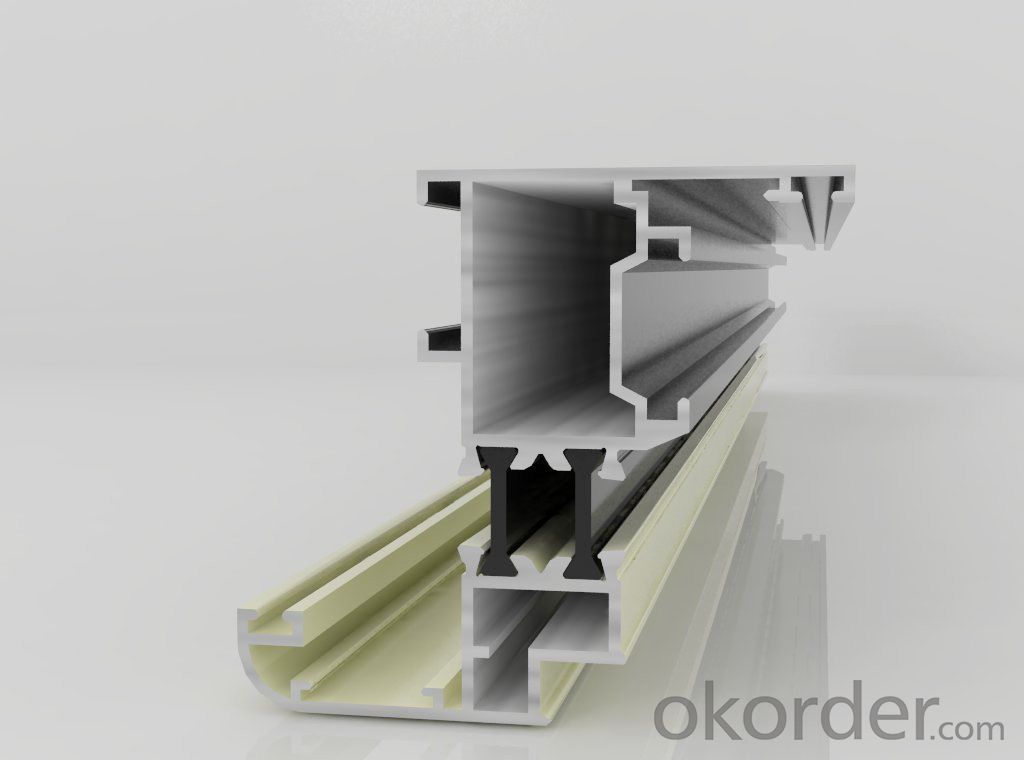

3.Aluminium Profile for Cars Auto-parts Good Quality Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. Aluminum is a lightweight yet strong material that offers numerous advantages for modular construction projects. Firstly, aluminum profiles have excellent structural integrity, making them suitable for supporting various loads in modular buildings. They can withstand heavy loads and provide stability, ensuring the integrity and safety of the entire structure. Secondly, aluminum profiles are corrosion-resistant, which is crucial for modular construction projects that may be exposed to different weather conditions. This resistance to corrosion enhances the durability and longevity of the modular constructions, reducing maintenance costs in the long run. Furthermore, aluminum is highly versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and adaptability in modular construction. This flexibility enables architects and engineers to create innovative and functional modular structures according to specific project requirements. In addition, aluminum profiles are lightweight compared to traditional building materials like steel, making them easier to transport and handle during the construction process. This lightness also contributes to reducing the overall weight of the modular constructions, which can be beneficial in terms of transportation costs and foundation requirements. Moreover, aluminum is a sustainable material as it is 100% recyclable, and its production process requires less energy compared to other materials. This makes it an environmentally friendly choice for modular construction projects, aligning with the growing demand for sustainable building practices. Overall, aluminum profiles offer a range of advantages that make them highly suitable for modular construction. Their strength, corrosion resistance, versatility, lightweight nature, and sustainability make them an ideal choice for creating durable, customizable, and efficient modular structures.

- Q: Can aluminum profiles be bent or shaped?

- Yes, aluminum profiles can be bent or shaped. Aluminum is a highly versatile and malleable metal that can be easily formed into various shapes and configurations. The process of bending or shaping aluminum profiles involves applying heat and force to the metal, which allows it to be manipulated into the desired form. This flexibility makes aluminum profiles an ideal choice for a wide range of applications, such as construction, automotive, and aerospace industries, where lightweight and durable materials are required. Additionally, aluminum profiles can also be extruded, which involves pushing the metal through a die to create a specific shape or cross-section. Overall, the ability to bend and shape aluminum profiles makes them a popular choice for many industries.

- Q: Can aluminum profiles be used in electrical panel manufacturing?

- Indeed, electrical panel manufacturing can incorporate aluminum profiles. Aluminum, renowned for its lightweight and enduring nature, boasts remarkable electrical conductivity, rendering it apt for electrical panel applications. Moreover, its proficiency in heat dissipation proves vital in averting system overheating. Aluminum profiles can be effortlessly shaped and tailored to adhere to the unique prerequisites of electrical panel designs. In addition, aluminum's resistance to corrosion guarantees the durability of the electrical panel. Overall, owing to their myriad advantages, aluminum profiles remain a favored option in electrical panel manufacturing.

- Q: Aluminum profile spraying process

- Pretreatment -- drying, removing moisture -- spraying -- Inspection -- baking -- Inspection -- finished.1, construction requirements, general powder spraying construction requirements:(1) in order to give full play to and extend the service life of the coating, the surface of the coating is strictly treated by surface pretreatment first(2) when spraying, the coating must be completely ground to increase the spraying efficiency of the powder coating(3) to be coated with larger surface defects, it should be coated with conductive putty to ensure the smooth and smooth coating(4) after the spraying, the objects and articles should be heated, cured and solidified. The technical indexes of the powder products should be adopted, but the curing temperature and time should be guaranteed so as to avoid the quality failures caused by solidification(5) check immediately after spraying, if found defects should be timely treatment, if after curing defects are found, the only local small range without affecting, the coated surface decoration, can use the same color powder and acetone diluted to repair, if the scope is large and affects the surface quality, use sandpaper after again. Or use the paint remover to remove the coating, re Suo powder.(6) the recovered powder must be screened and removed, and then mixed with the new powder at a certain proportion(7) the powder supply barrel, the powder spraying room and the recycling system should avoid contamination by other colors. Therefore, each color change must be cleaned

- Q: What does "3030W" W mean for European standard industrial aluminum?

- This refers to the 3030 heavy aluminum profiles. General aluminum profile manufacturers will make a number of their own products, European standard 3030 series has a variety of specifications, such as Jing Teng aluminum European standard 3030R, referring to the European standard 3030 fan, 3030G refers to the 3030 GB profiles. In short, look at your own needs,

- Q: Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Are you looking at these? These are new standards for 2008, and there are many I haven't listed. You can come here and see it. It's easy to find!Standard number: GB 5237.1-2008Standard Name: aluminium alloy construction profile first parts: base materialStandard status: not implementedEnglish Title: Wrought, aluminium, alloy, extruded, profiles, for, architecture -, Part, 1:Mill, finish, profilesAlternatives: instead of GB 5237.1-2004Date of implementation: 2009-9-1Promulgated by: China Nonferrous Metals Industry AssociationDescription: this standard specifies the lighting measuring instruments, measuring methods and measurement contents in indoor and outdoor lighting placesThis standard applies to the measurement of indoor lighting, the measurement of outdoor lighting places such as roads, squares and outdoor work areas, and the measurement of night lighting of buildingsStandard number: GB 5237.2-2008Standard Name: aluminum alloy building profile second parts: anode oxidation section

- Q: This question seeks to understand the various types of aluminum profiles that are specifically used in the construction of building facades.

- <p>Aluminum profiles for facades come in various types, each serving different purposes and functions. Common types include: 1. <strong>Vertical and Horizontal Mullions</strong>: These are the primary structural elements that form the framework of the facade. 2. <strong>Transoms and Muntins</strong>: Used to divide the glass into panels, providing both aesthetic appeal and structural integrity. 3. <strong>Capping Profiles</strong>: These cover the ends of the mullions, providing a finished look and protecting the edges. 4. <strong>Cover Caps</strong>: Used to conceal the fasteners and provide a clean, streamlined appearance. 5. <strong>Angle Connectors</strong>: Facilitate the connection of different profile sections at various angles. 6. <strong>Gaskets and Seals</strong>: Ensure weatherproofing and insulation. 7. <strong>Accessories</strong>: Such as handles, locks, and hinges, which are integrated into the facade system. Each type is designed to meet specific performance requirements, such as load-bearing capacity, resistance to environmental factors, and aesthetic considerations.</p>

- Q: How do you attach accessories or components to aluminum profiles?

- There are several ways to attach accessories or components to aluminum profiles. One common method is to use T-slot nuts and bolts. T-slot nuts slide into the T-slot groove on the profile and can be positioned anywhere along the length. The bolts then secure the accessory or component to the nut, creating a strong and secure connection. Another option is to use brackets or mounting plates specifically designed for aluminum profiles. These brackets usually have pre-drilled holes that align with the T-slot grooves, allowing for easy attachment of accessories. They can be fastened to the profile using screws or bolts. Additionally, there are various specialized connectors available for specific applications. Examples include corner connectors, joining plates, and hinge connectors. These connectors provide easy and reliable ways to attach accessories or components to aluminum profiles without the need for additional drilling or machining. It is important to consider the weight and load-bearing requirements of the accessories or components when choosing the attachment method. Using appropriate fasteners and connectors ensures a secure attachment and prevents any potential hazards.

- Q: What is the limitation of aluminum bending

- Stretch before aging. After aging, the hardness of the material is higher, and then the tension bend is cracked.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a lightweight and durable material, making it an excellent choice for greenhouse construction. It is resistant to corrosion, which is important in a moist and humid environment like a greenhouse. Aluminum profiles can be easily fabricated and assembled, allowing for flexibility in design and construction. Additionally, aluminum is a sustainable material as it is 100% recyclable, making it environmentally friendly for greenhouse construction. Overall, aluminum profiles are a practical and reliable option for building greenhouses.

Send your message to us

Aluminum T Slot Extrusion Profiles for Cars - High Quality Auto-Parts Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords