Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

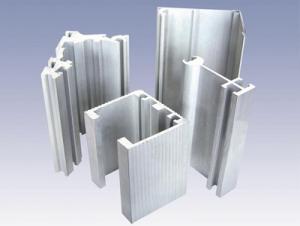

1.Structure of Product Description

Cold rolled aluminum sheet and cold rolled stainless steel sheet are all widely used in the field of construction field and decoration field, etc.

There are many different grades, su cnbm INTERNATONAL copratoion mainly goods are all including ch as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

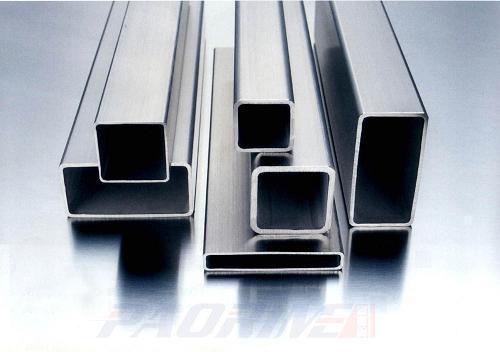

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000MM,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLAND, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum profiles suitable for automotive heat exchangers?

- Yes, aluminum profiles are suitable for automotive heat exchangers. Aluminum offers several advantages that make it an ideal material for heat exchanger applications in automobiles. Firstly, aluminum has excellent thermal conductivity, which means it can efficiently transfer heat from one medium to another. This property allows aluminum heat exchangers to effectively dissipate heat generated by the engine, transmission, or other components in the vehicle. Secondly, aluminum profiles are lightweight yet strong, making them a preferred choice in the automotive industry where weight reduction is crucial for improved fuel efficiency and performance. The use of aluminum heat exchangers can contribute to overall weight reduction, leading to better handling, acceleration, and energy efficiency. Additionally, aluminum is highly corrosion-resistant, even in harsh environments, making it suitable for automotive applications. This resistance to corrosion ensures the longevity and reliability of the heat exchangers, reducing maintenance and replacement costs. Furthermore, aluminum profiles can be easily manufactured and formed into complex shapes, allowing for customized designs that fit specific automotive requirements. This flexibility in design enables efficient use of available space and maximizes the heat exchange surface area, enhancing overall performance. In conclusion, aluminum profiles are well-suited for automotive heat exchangers due to their excellent thermal conductivity, lightweight yet strong characteristics, corrosion resistance, and flexibility in design. These qualities make aluminum an ideal choice for effectively managing heat in vehicles, contributing to improved performance, fuel efficiency, and durability.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems for residential buildings?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems in residential buildings. They are known for their durability, corrosion resistance, and low thermal conductivity, which makes them ideal for creating thermal barriers. Aluminum profiles can support the structure of the insulation system, providing a stable framework while also contributing to energy efficiency by reducing heat transfer. However, it's important to ensure that the profiles are properly sealed and insulated to prevent thermal bridging and to maintain the overall insulation performance of the building envelope.</p>

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: What are the various materials incorporated in the production of aluminum profiles?

- <p>Aluminum profiles are primarily made from aluminum alloys, which can include different elements to enhance properties such as strength, corrosion resistance, and machinability. Commonly used alloys are 6063, 6061, and 6082. Other materials may include magnesium, silicon, copper, manganese, and zinc, which are added to achieve specific alloy characteristics. Some profiles may also incorporate reinforcing materials like fiberglass or steel for added strength, or coatings such as anodized layers, powder coating, or paint for improved aesthetics and corrosion resistance.</p>

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles to building structures.

- <p>There are several types of adhesives used to attach aluminum profiles to building structures, including epoxy adhesives, which offer high strength and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion on a variety of surfaces and are resistant to UV light; and silicone adhesives, which are excellent for sealing and bonding in environments with fluctuating temperatures. Each adhesive type has specific properties that make it suitable for different applications and environmental conditions in construction.</p>

- Q: What are the reasons for the large number of products in the aluminum profile cutting machine after opening?

- When sawing, lubrication is insufficient, check the lubrication system, and the other may be aluminum material is not good

- Q: Can aluminum profiles be used for security doors and windows?

- Indeed, security doors and windows can be constructed using aluminum profiles. Aluminum, known for its robustness and resilience against corrosion, proves to be a highly suitable material for security purposes. By tailoring the design and production of aluminum profiles, specific security needs can be met, including fortified frames, multi-point locking mechanisms, and glass that can withstand impacts. Moreover, aluminum profiles offer a sophisticated and contemporary appearance, enabling the creation of elegant security doors and windows. Ultimately, aluminum profiles offer a dependable and secure option to enhance the safety and safeguard residential and commercial properties alike.

- Q: Are aluminum profiles suitable for industrial workstations?

- Industrial workstations can benefit from the use of aluminum profiles. This material, known for its lightweight and durability, offers exceptional strength and stability, making it highly suitable for industrial environments. The corrosion resistance of aluminum is also noteworthy, as it extends the lifespan of workstations. Moreover, the flexibility of aluminum profiles allows for easy customization and assembly, enabling the design of workstations that meet specific industrial requirements. Another advantage is that aluminum is an environmentally friendly material, as it can be completely recycled. This aligns with the growing focus on sustainability in the industrial sector. In conclusion, aluminum profiles provide numerous benefits for industrial workstations, making them a suitable choice for various applications in industrial settings.

- Q: This question asks for a list of various types of adhesives that are typically used in conjunction with aluminum profiles in construction projects.

- <p>Common types of adhesives used with aluminum profiles in construction include epoxy resins, which offer strong bonding and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; silicone adhesives, which are excellent for sealing and bonding in a wide range of temperatures; acrylic adhesives, valued for their versatility and quick setting times; and cyanoacrylate or 'super glue', which bonds quickly and is great for small, precise applications. Each type has unique properties that make it suitable for different construction needs.</p>

- Q: Are aluminum profiles suitable for decorative applications?

- <p>Yes, aluminum profiles are commonly used for decorative purposes. They offer a sleek, modern look and are lightweight, durable, and resistant to corrosion. They can be anodized or powder coated in various colors to match different design aesthetics. Aluminum profiles are versatile and can be used in architectural features, furniture, and various other decorative elements.</p>

Send your message to us

Aluminum T Extrusion Profiles - Cold Rolled Aluminum Sheet Cold Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords