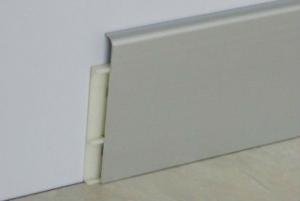

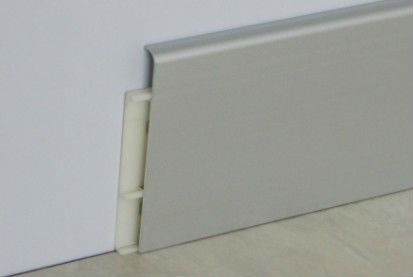

China Anodized Aluminum Frame Profiles - Aluminum Skirting Board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminum skirting board 6063-T5

Main Characters

Functions: Visual balance; Decoration prettification; Protection for wall’s corners and floor.

Materials: Al 6063-T5

Hardness: 13~15 Degrees

Lifelong: 25 years over

Merits: Anti-fading; High Strength; Non-deformation; Water proof; Dump proof; Mothproof; Anti-friction; Aging resistance; Eco care; Recyclable; Easy to install;

- Q: Is it possible to recycle aluminum profiles and use them again in construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Recycled aluminum maintains its properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: This question asks about the various types of insulation panels that utilize aluminum profiles in their construction.

- <p>Insulation panels made from aluminum profiles come in several types, each with specific characteristics and applications. These include: 1. Sandwich Panels, which consist of two aluminum sheets with a core material like polyurethane, rockwool, or polystyrene. 2. Composite Panels, which combine aluminum with other materials for enhanced properties. 3. Structural Insulated Panels (SIPs), used in construction for their thermal efficiency and strength. 4. Cold Storage Panels, designed to maintain low temperatures in refrigeration units. 5. Acoustic Insulation Panels, which reduce noise transfer. Each type is chosen based on the required thermal, acoustic, and structural performance.</p>

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: Calculation of heat dissipation of aluminium profile radiator

- This requires software that is not easy to compute directly, and the formulas may pull out a long string and are inaccurateBecause the contact of the bottom of the profile is initiated by the heat source, the contact area is first set, which affects the distance and conduction angle of the thermal conductivityWhen you change this condition, the whole formula varies greatlyAgain, set convection and convection intensities, convection fluid properties and relative heat exchange efficienciesIn the radiator industry, there have been similar formulas, but only the natural convection settings, and in the heat under the state, heat dissipation at room temperature settingsProfessional software has many, FLOWTHEM, e-therm, ice-pake and so on, even Pro-E seems to be able to hang modules to do simulationSuggest going directly to software

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the design specifications and dimensions of the project, including the length, width, and height of the structure. 2. Identify the types and sizes of aluminum profiles required based on the structural needs and design. 3. Calculate the total linear footage of each profile type needed by multiplying the length of each required section by the number of sections. 4. Add up the total linear footage for all profile types. 5. Account for waste and cutting losses, typically adding 5-10% to the total. 6. Ensure the calculations comply with building codes and safety standards. Consult with engineers or architects if necessary.</p>

- Q: What do you mean by aluminum alloy T3-T8? Someone who answers me, thanks a lot

- Aluminum alloy profile T3 refers to natural aging after solid solution treatment.Aluminum alloy profile T8 refers to solution treatment, cold work, artificial aging.

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: What materials are used for aluminum profile packing?

- Aluminum packaging standard is generally pearl cotton and kraft paper packaging, but depends on the degree of product requirements,

Send your message to us

China Anodized Aluminum Frame Profiles - Aluminum Skirting Board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords