Sheets of Anodized Aluminum Alloy 6063/Aluminum Alloy 6000 Series, 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

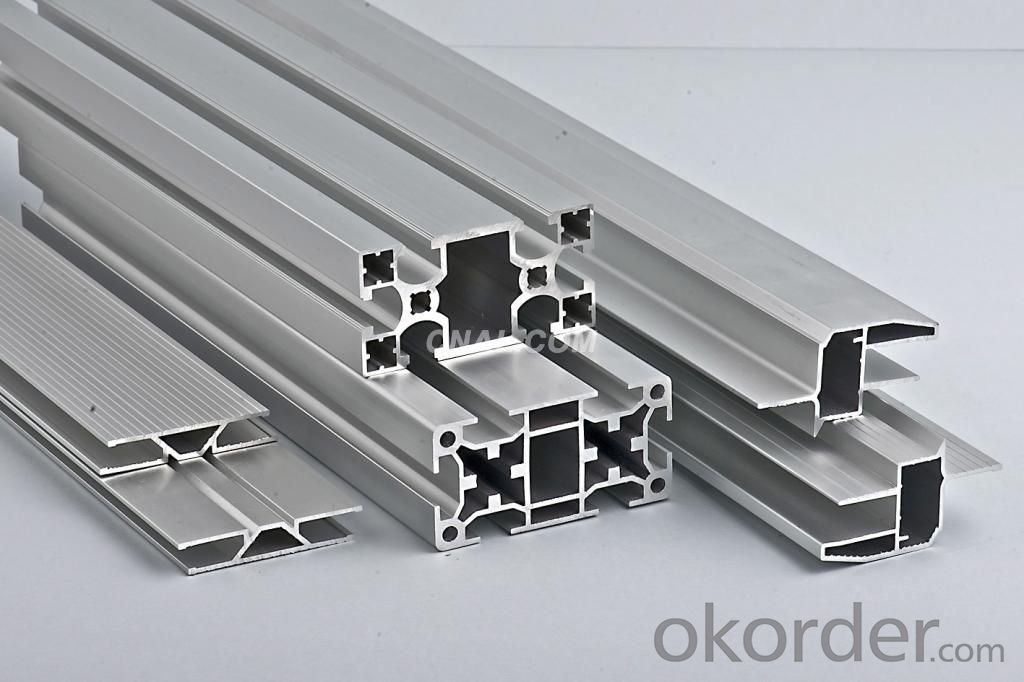

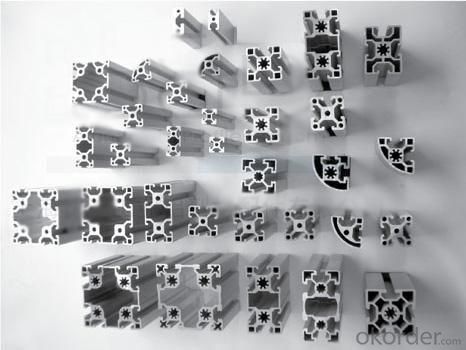

Images of the Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles:

Aluminium Alloy 6063/Aluminum Alloy 6000 Series,6063 T5 Aluminum Extruded Profiles Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- The clearance value of the stretched aluminum plate is =1.3~1.4t (first stretch), 1.15~1.2t (second times stretch), and 1.1t (last stretch). The tensile properties of aluminum sheets are inferior to those of low carbon steel, and they are easily broken when stretched. The tensile height 45mm depends on the diameter of the drawing piece. A cylindrical part of a large cross-sectional area from a material to a small cross section is called a tensile coefficient. That is, the ratio of the cross-sectional area to the cross-sectional area before stretching, i.e., m=A0/An-1. For cylindrical parts, m1=d1/D0, the coefficient of the first stretch can be around 0.5, i.e., the diameter after the first stretch is 1/2 of the blank diameter before the drawing. In the future, the tensile coefficients are usually around 0.7~0.8. The calculation of drawing blank, roughly calculate the blank size according to the principle of equal area of the blank before and after the drawing.

- Q: The question asks about the duration aluminum sheets can last and how this compares to the lifespan of other materials.

- <p>The lifespan of aluminum sheets can vary significantly based on the environment and usage conditions. Generally, aluminum sheets have a long lifespan, often lasting 50 years or more without significant deterioration when properly maintained. This durability makes aluminum sheets a popular choice for construction and manufacturing applications. Compared to other materials, such as steel, aluminum is lighter and more resistant to corrosion, which can extend its lifespan in certain environments. However, steel may be more suitable for applications requiring high strength, while aluminum excels in applications where weight and corrosion resistance are priorities.</p>

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. Aluminum is a popular material choice for HVAC systems due to its various beneficial properties. Firstly, aluminum is lightweight yet strong, making it easy to handle and install in HVAC systems. Its low density also allows for cost-effective transportation and reduces the overall weight of the HVAC units. Secondly, aluminum has excellent corrosion resistance. HVAC systems often encounter moisture and condensation, especially in air conditioning units, and aluminum's resistance to corrosion ensures its durability and longevity in such environments. Additionally, aluminum sheets have good thermal conductivity, allowing for efficient heat transfer throughout the HVAC system. This property is particularly important in heating and cooling applications, as it helps to distribute the desired temperature effectively. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems that circulate air throughout buildings. It does not release any harmful particles or gases into the air, ensuring the quality of indoor air. Lastly, aluminum is a highly recyclable material, making it environmentally friendly. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability goals. Considering all these advantages, aluminum sheets are indeed suitable for use in HVAC systems, providing an optimal balance of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

- Q: What is the elongation percentage of 101 aluminum sheets?

- The elongation percentage of 101 aluminum sheets typically ranges between 12% and 30%, depending on the specific grade and thickness of the sheet.

- Q: Are aluminum sheets resistant to UV radiation?

- Yes, aluminum sheets are highly resistant to UV radiation.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q: Are aluminum sheets fire resistant?

- Yes, aluminum sheets are fire resistant.

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a lightweight and durable material that can be easily shaped and manipulated to create various designs for lighting fixtures. It also has excellent heat dissipation properties, which is crucial for ensuring the longevity and performance of lighting fixtures. Additionally, aluminum is corrosion-resistant, making it suitable for both indoor and outdoor lighting applications.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

- Q: What are the different methods for engraving aluminum sheets?

- Engraving aluminum sheets can be done using various methods, each with its own benefits and uses. 1. Laser engraving: Among the most popular techniques is laser engraving, which employs a laser beam to vaporize the aluminum surface, resulting in a permanent and precise engraving. This method offers great precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: Another method involves utilizing a mechanical tool, like a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. This approach enables deep and intricate engravings, making it ideal for applications that prioritize durability and depth. 3. Chemical etching: For highly precise and intricate designs, chemical etching is often used. This method selectively removes material from the aluminum surface using chemicals. It is commonly employed in industries such as electronics and aerospace, where precision and high-quality finishes are vital. 4. CNC milling: By utilizing a computer-controlled machine, known as Computer Numerical Control (CNC) milling, material can be removed from the aluminum sheet with precision and complexity. This technique is well-suited for applications that require intricate or 3D engravings. 5. Hand engraving: For artistic freedom and customization, hand engraving is an option. This method involves manually creating engravings on the aluminum surface using handheld tools like gravers or chisels. While it may not offer the same level of precision as other methods, hand engraving allows for personalization. The choice of engraving method depends on various factors such as the desired design, level of detail, production volume, and budget. Each technique has its own advantages and limitations.

Send your message to us

Sheets of Anodized Aluminum Alloy 6063/Aluminum Alloy 6000 Series, 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords