Hafele Aluminum Profiles for Curtain Wall - Extrusion Profiles Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Extrusion Profile for Curtain Wall Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Extrusion Profile for Curtain Wall Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Extrusion Profile for Curtain Wall Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

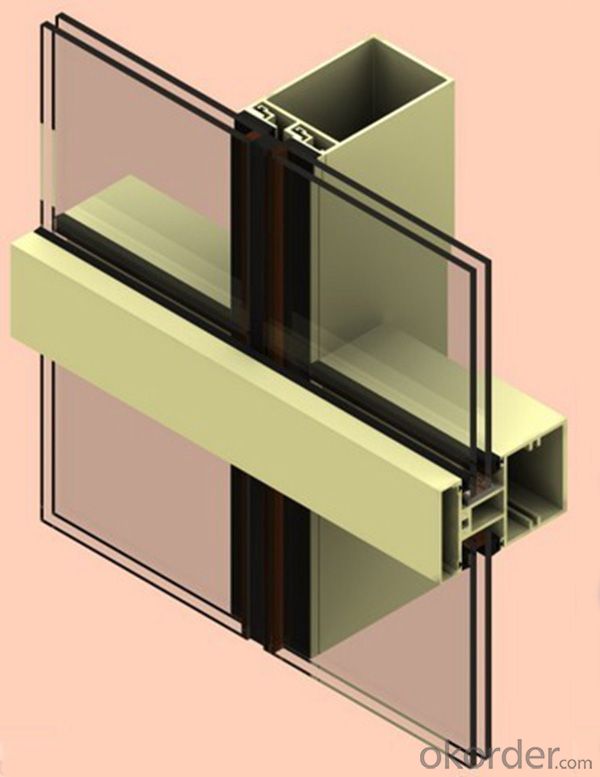

5. Image of Aluminum Extrusion Profile for Curtain Wall Made in China

6. Package and shipping of Aluminum Extrusion Profile for Curtain Wall Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: Do aluminum profiles require any special maintenance?

- There is no need for any special maintenance for aluminum profiles. They are durable and require minimal maintenance, as they are resistant to corrosion, rust, and weathering. Unlike wood or steel, aluminum profiles do not require regular painting, staining, or treatment to maintain their appearance or functionality. Moreover, aluminum is lightweight, making it easy to handle and install. However, it is essential to keep the aluminum profiles clean by regularly using a mild detergent and water solution to remove dirt or debris. This will help to maintain the profiles' aesthetic appeal and ensure their longevity. In summary, aluminum profiles are a convenient and hassle-free choice for various applications, as they do not demand any special maintenance.

- Q: This question asks for methods to prevent aluminum profiles from rusting during the transportation process.

- <p>To prevent rusting of aluminum profiles during transportation, ensure proper packaging with moisture-resistant materials. Use protective films or covers to shield the profiles from direct contact with moisture and humidity. Maintain a controlled environment in the transport vehicle, avoiding high humidity and condensation. Regularly inspect the profiles for any signs of moisture or damage and address them promptly. Additionally, consider using rust inhibitors or anti-corrosion coatings on the aluminum profiles before packaging. Always handle the profiles with care to avoid scratches or damage that could lead to rusting.</p>

- Q: Are aluminum profiles suitable for exhibition stands?

- Yes, aluminum profiles are suitable for exhibition stands. They are lightweight, durable, and can be easily customized to create unique and attractive display structures. Additionally, aluminum profiles allow for easy assembly and disassembly, making them a practical choice for exhibition stands that need to be frequently transported and set up at different locations.

- Q: What are the different sealing options for aluminum profiles?

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Q: What are the top 20 Chinese architectural aluminum profiles?

- 14, Fujian public security Aluminum Co. Ltd.15, Zhejiang pillars of new material Limited by Share Ltd16, Lear aluminum industry Limited by Share Ltd17 、 Ming emperor Aluminum Industry Co., Ltd.18, Guangdong silver100 innovation Aluminum Co. Ltd.19 、 Qingyuan Asia Aluminum Co., Ltd.20 、 Guanghan Sichuan Sanxing Aluminium Industry Co., Ltd.

- Q: Can aluminum profiles be used for exhibition stands?

- Yes, aluminum profiles can be used for exhibition stands. Aluminum profiles are lightweight and versatile, making them an ideal choice for exhibition stands. They can be easily assembled and disassembled, allowing for easy transportation and storage. Additionally, aluminum profiles can be customized to fit the specific design and layout requirements of an exhibition stand. They can be used to create frames, partitions, and display panels, providing a sturdy and professional-looking structure. The use of aluminum profiles in exhibition stands also offers the flexibility to add accessories such as lighting fixtures, shelving, and signage, further enhancing the overall visual appeal and functionality of the stand.

- Q: How to calculate the spraying powder of aluminium profile?

- If you are oily and material surface oxidation layer, the most complete process is: in addition to the principle of oil - water - rust - powder coating construction technology and requirement of the powder electrostatic spraying is the use of high-voltage corona electrostatic electric field. stay

- Q: This question asks about the various methods used to finish aluminum profiles, including painting and coating.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance, durability, and functionality. Common methods include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, an electrostatic process that offers a durable and colorful finish. 3. Painting, which can be done with various types of paint for aesthetic or protective purposes. 4. Polishing, which gives a shiny, smooth surface finish. 5. Brushing, creating a textured, satin-like appearance. 6. Electroplating, which deposits a thin layer of metal onto the aluminum for decorative or protective reasons. Each method has its advantages and is chosen based on the specific requirements of the application.</p>

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

Send your message to us

Hafele Aluminum Profiles for Curtain Wall - Extrusion Profiles Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords