T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

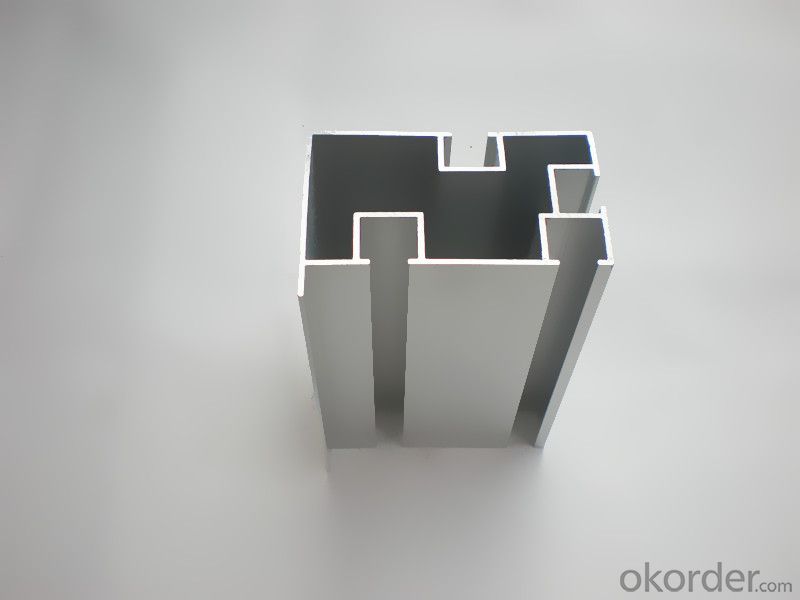

1.Structure of Aluminum Profile 6063 t5 Aluminum Extruded Profiles Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6063 t5 Aluminum Extruded Profiles :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

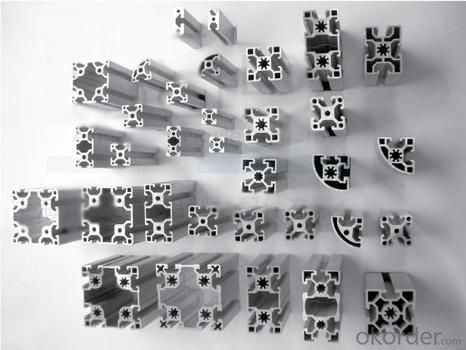

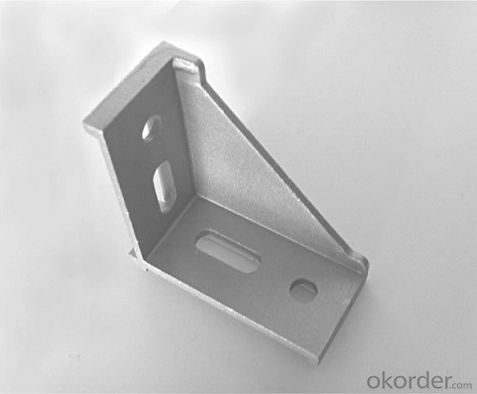

3.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Images:

4.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of roofs.

- <p>Aluminum profiles in roofing offer several advantages, including their lightweight nature which reduces structural load, high corrosion resistance making them suitable for various climates, and ease of installation which can lower labor costs. They also have a long lifespan and can be recycled, contributing to sustainability. However, there are disadvantages such as higher initial costs compared to traditional materials, potential for dents or damage from impacts, and the need for regular maintenance to preserve their finish and prevent fading. Additionally, aluminum can be noisy during rain or hail, and it may not be as thermally efficient as some other roofing materials, potentially requiring additional insulation.</p>

- Q: This question asks about the various applications of aluminum extrusions within the automotive manufacturing industry.

- <p>Aluminum extrusions are widely used in automotive manufacturing due to their lightweight, high strength, and corrosion resistance. They are utilized in several areas: 1) Structural components such as chassis, frames, and body parts to reduce vehicle weight and improve fuel efficiency. 2) Engine components to enhance engine performance and durability. 3) Heat exchangers and radiators for effective cooling systems. 4) Crash management systems to absorb impact during collisions. 5) Interior components like dashboards and door panels for lightweight and aesthetic appeal. 6) Electrical components such as battery casings and wiring harnesses. 7) Wheels and suspension components for improved handling and reduced unsprung weight. These applications contribute to the overall performance, safety, and efficiency of vehicles.</p>

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Aluminum alloy material3.2.1 glass curtain wall by chemical composition corresponding to Aluminum Alloy material grades should be consistent with current national standard "the relevant provisions of the chemical composition" deformation of aluminum and Aluminum Alloy GB / T 3190, the quality of Aluminum Alloy section shall comply with the provisions of the current national standard "Aluminum Alloy architecture" GB / T 5237, section size deviation should be allowed to high grade or ultra high grade.3.2.2 Aluminum Alloy profiles by anodic oxidation, electrophoretic coating, powder coating, fluorocarbon paint spraying surface treatment, quality should be consistent with current national standard "Aluminum Alloy architecture" GB / T 5237 requirements, the thickness of surface layer should meet the requirements in table 3.2.2.3.2.3 insulated aluminum profiles produced by the strip process shall be made of PA66GF25 (polyamide 66+25 glass fiber) material and shall not be made of PVC material. A heat insulated aluminum profile produced by pouring process shall be made of PUR (polyurethane) material. The shear strength of the joint must meet the design requirements.3.2.4 and glass curtain wall matching aluminum alloy doors and windows should comply with the current national standard "aluminum alloy door", GB / T 8478 and aluminum alloy window "GB/T 8479" provisions.

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- You mold two boxes connected at a relatively small, may die requirements will be much higher, I do not know whether the price will be more expensive.

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Features of aluminum profiles

- Corrosion resistanceThe density of aluminum profile is only 2.7g/cm3, about 1/3 of steel, copper or brass (7.83g/, cm3, 8.93g/, cm3), respectively. Aluminum can show excellent corrosion resistance in most ambient conditions, including air, water (or brine), petrochemical, and many chemical systems nductivityAluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper.

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

- Q: What specific considerations should be taken into account when using aluminum profiles in extreme temperatures, be it cold or hot?

- <p>Aluminum profiles are generally durable and can withstand a wide range of temperatures. However, in extremely cold climates, thermal contraction can occur, potentially leading to gaps or cracks. It's important to allow for expansion and contraction in the design. In hot climates, while aluminum doesn't lose strength, it can expand and warp if not properly supported. Additionally, it can become hot to the touch, which may require protective measures to prevent burns. Always ensure that aluminum profiles are of high quality and are designed for the specific climate conditions they will be exposed to.</p>

Send your message to us

T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords