Sheets of Aluminum 6061 for Sale - Window and Door System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Sheets 6061 for Window And Door System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Aluminum Sheets 6061 for Window And Door System

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Sheets 6061 for Window And Door System

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

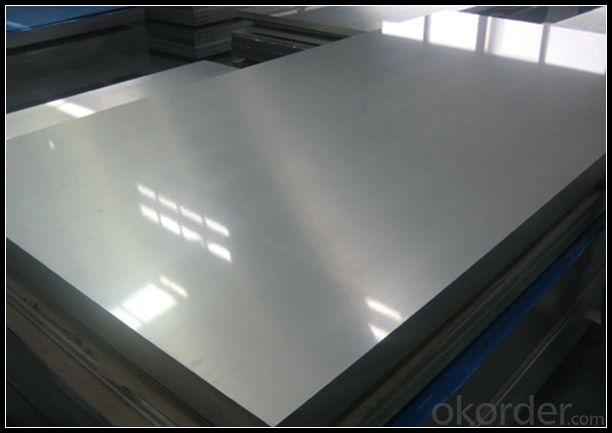

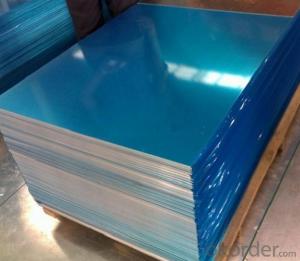

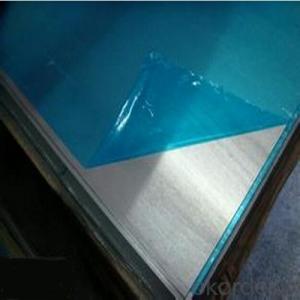

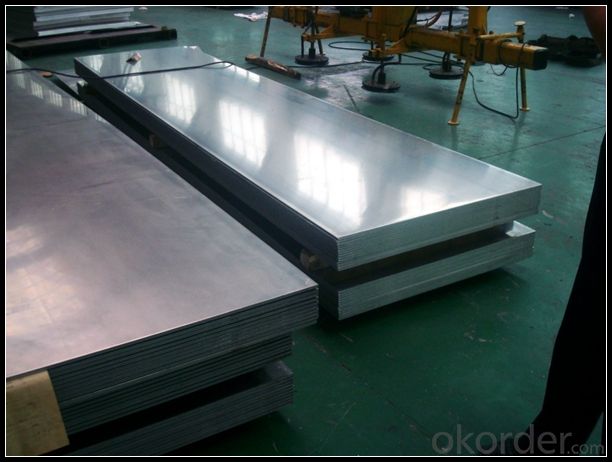

5. Image of Aluminum Sheets 6061 for Window And Door System

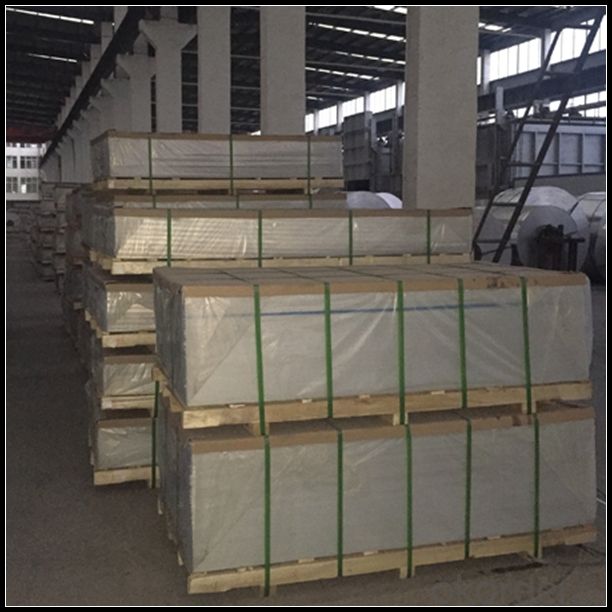

6. Package and shipping of Aluminum Sheets 6061 for Window And Door System

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Yes, aluminum sheets are suitable for electrical conductivity applications.

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The surface roughness of an aluminum sheet can significantly affect its overall performance. The roughness of the surface refers to the irregularities, bumps, and texture present on the sheet's surface. These irregularities can be measured using various methods, such as Ra (arithmetical average roughness) or Rz (mean roughness depth). One significant impact of surface roughness on aluminum sheet performance is in its ability to bond or adhere to other materials. A smoother surface allows for better adhesion, whether it is through welding, gluing, or painting. When the surface is rough, it creates less contact area and reduces the strength of the bond. This is particularly crucial in applications where the aluminum sheet is used as a structural component or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's ability to reflect light. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. In contrast, a rough surface scatters light in multiple directions, reducing its overall reflectivity. This property is relevant in applications such as architectural cladding, where the desired aesthetic appearance may rely on the sheet's ability to reflect light consistently. Moreover, the surface roughness of aluminum sheets can impact their corrosion resistance. A smoother surface is less prone to corrosion as it provides fewer sites for corrosion initiation. On the other hand, a rougher surface may have micro crevices or grooves that can trap moisture, salts, or other corrosive substances, accelerating the corrosion process. In applications where corrosion resistance is critical, such as marine environments or outdoor structures, maintaining a smooth surface is essential. Lastly, surface roughness affects the sheet's mechanical properties. A rough surface can act as stress concentrators, leading to increased susceptibility to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet plays a vital role in its performance. It impacts adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, considering and controlling the surface roughness is essential in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

- Q: Can aluminum plate protect against radiation?

- It can only about radiation, and other materials have not heard of this performance.

- Q: Can aluminum sheets be used for lithographic printing?

- Indeed, lithographic printing can make use of aluminum sheets. This widely-used printing method, also referred to as offset printing, involves the transfer of an image from a plate onto a rubber blanket and subsequently onto the printing surface. Aluminum sheets are frequently employed as the foundational material for lithographic plates due to their exceptional durability, lightweight composition, and capacity to retain intricate details. Typically, these aluminum sheets utilized in lithographic printing are coated with a photosensitive emulsion, facilitating the precise and accurate transfer of the image onto the printing surface. Consequently, aluminum sheets represent an optimal selection for lithographic printing, particularly for extensive and high-quality printing endeavors.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Yes, aluminum sheets are suitable for manufacturing audio speaker enclosures. Aluminum is a lightweight and durable material that is commonly used in the production of speaker enclosures. It has excellent acoustic properties, allowing for clear and accurate sound reproduction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the speaker enclosure. Furthermore, aluminum can be easily molded and shaped into various designs, allowing for flexibility in the manufacturing process. Overall, aluminum sheets are a suitable choice for manufacturing audio speaker enclosures due to their acoustic properties, durability, and versatility.

Send your message to us

Sheets of Aluminum 6061 for Sale - Window and Door System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords