Aircraft Aluminum Sheets for Sale with Good Price in Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet/slab/plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series,

8000 series,etc. The detailed grade

1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

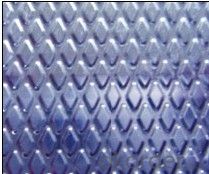

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500*3000mm,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 200mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 4 tons/each size.

How many tons did you export in one year

Fiji,Indonesia,Canada, Vietnam,Turkey,etc.

What is your basic products?

---Normally they are aluminum sheet,checkered sheet, checkered slab, etc. big and small-5-bar aluminium checkered sheet, big-5-bar

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: Is it possible to utilize aluminum sheets in the interior design of vehicles?

- <p>Yes, aluminum sheets can be used for car interiors. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications such as door panels, dashboards, and trim. Aluminum's malleability allows for easy shaping into complex designs, and it can be finished in various ways to match the aesthetic of the vehicle's interior. Additionally, its strength-to-weight ratio contributes to fuel efficiency and performance. However, it's important to consider the specific alloy and treatment of the aluminum to ensure it meets safety and comfort standards.</p>

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- No... all of their computers are made of aluminum (except for the old white macbook) so it'd be kind of hard for them to stop selling aluminum computers. Which one were you looking at? the iMac, mac mini, macbook pro? If you were looking for the regular macbook you probably only saw the plastic white one because as of today, apple decided that the 13inch aluminum unibodies were going to be added to the pro line. They saw a slight spec bump and now come with a new and improved battery and I believe faster processors, but all in all, still the same macbook, just with a new name. Check the macbook pro section.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What are the various types of insulation materials that can be combined with aluminum sheets for thermal or acoustic insulation purposes?

- <p>There are several types of insulation that can be used in conjunction with aluminum sheets, including: 1. Polyurethane foam, which provides excellent thermal insulation and can be bonded to aluminum sheets. 2. Mineral wool, a fire-resistant material that offers both thermal and acoustic insulation. 3. Polyisocyanurate, known for its high R-value and can be laminated to aluminum for added strength. 4. Extruded polystyrene, which is lightweight and provides good thermal resistance. 5. Fiberglass, a versatile insulation material that can be combined with aluminum for various applications. Each type has its specific properties and applications, making them suitable for different environments and insulation needs.</p>

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on factors such as size, thickness, and quantity. It is best to check with suppliers or retailers for current pricing information.

- Q: Is it possible to use aluminum sheets in environments with low temperatures?

- <p>Yes, aluminum sheets can be used in cold climates. Aluminum has excellent corrosion resistance and maintains its strength in low temperatures, making it suitable for use in cold environments. It does not rust or corrode easily, which is beneficial in harsh weather conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper installation and design considerations are necessary to account for these properties in cold climates.</p>

- Q: Can aluminum sheets be used for air ducts?

- Indeed, air ducts can utilize aluminum sheets. Aluminum, known for its lightweight and durable characteristics, is frequently employed in air ducts. Its resistance to corrosion renders it a suitable option for HVAC systems. Air ducts are often constructed using aluminum sheets due to their malleability, enabling easy bending and shaping to meet specific dimensions. Moreover, aluminum boasts commendable thermal conductivity, ensuring efficient heat transfer within the ducts. Ultimately, opting for aluminum sheets in air ducts proves to be a pragmatic and efficient decision.

- Q: Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

Send your message to us

Aircraft Aluminum Sheets for Sale with Good Price in Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords