Aluminum Sheets New York - Aluminum Sheet 6061 for Window and Door System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

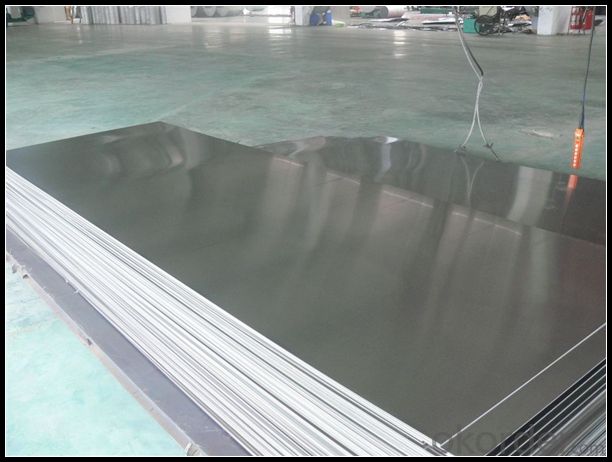

1.Structure of Aluminum Sheet 6061 for Window And Door System

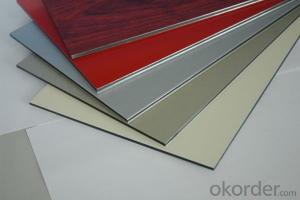

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheet 6061 for Window And Door System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Aluminum Sheet 6061 for Window And Door System Images

4.Specification of Aluminum Sheet 6061 for Window And Door System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- i might call the plumber immediately. curiously there's a hollow interior the piping someplace, and the sulfuric acid would desire to have eaten by in spite of advance into clogging that hollow. I doubt that it will supply up leaking via itself, to no longer point out that acid is in all risk leaking into your kitchen in the present day.

- Q: Can the aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a preferred material for solar panel frames due to its lightweight, durable, and corrosion-resistant properties. It provides structural stability and ease of installation for the solar panels.

- Q: Are the aluminum sheets suitable for manufacturing food processing equipment?

- Aluminum sheets, indeed, prove to be fitting for the production of food processing equipment. This metal, lightweight and enduring, possesses resistance against corrosion, rendering it exceptionally suitable for deployment within the food industry. Moreover, aluminum is free from toxicity, odorlessness, and devoid of any detrimental impact on the flavor or excellence of the processed food. Furthermore, aluminum can be effortlessly cleansed and maintained, thus guaranteeing adherence to hygiene guidelines. Additionally, owing to its capacity to proficiently conduct heat, aluminum serves as an apt choice for cooking and baking applications. All in all, the myriad advantageous attributes of aluminum sheets establish them as a widely favored option for the manufacture of food processing equipment.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Medical equipment applications can involve anodizing 101 aluminum sheets, which creates a protective layer on the surface of the aluminum. This process enhances corrosion resistance, durability, and the overall aesthetic appearance. Anodizing is commonly used in the medical industry to improve equipment performance and longevity, as well as to maintain cleanliness and sterility. The specific alloy, such as 101, does not typically affect the anodizing process, as it can be applied to various grades of aluminum. However, it is crucial to consult with an anodizing specialist or manufacturer to ensure that the specific alloy is suitable for the intended medical equipment application and to determine the most appropriate anodizing process and specifications.

- Q: whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q: Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet strongly influences its mechanical properties. The mechanical properties of aluminum sheet can include tensile strength, yield strength, elongation, hardness, and fatigue strength, among others. Firstly, the alloy composition affects the overall strength of the aluminum sheet. Aluminum alloys are typically mixed with other elements such as copper, manganese, magnesium, and silicon to enhance their mechanical properties. These alloying elements form solid solutions or precipitates within the aluminum matrix, which can significantly increase the strength of the material. For example, adding copper to aluminum forms a solid solution that increases the tensile strength and yield strength of the sheet. Secondly, the alloy composition affects the ductility and formability of the aluminum sheet. Some alloying elements, such as magnesium and silicon, can reduce the ductility of aluminum alloys. This reduction in ductility can make the sheet more prone to cracking or fracturing under stress. On the other hand, certain alloying elements can improve the formability of aluminum sheet, making it easier to shape or bend without cracking. Furthermore, the alloy composition also influences the resistance to corrosion and heat of aluminum sheet. For instance, aluminum alloys with a high content of magnesium, such as the 5000 series, exhibit excellent resistance to corrosion and are commonly used in marine applications. Additionally, some aluminum alloys are developed specifically for high-temperature applications, with alloying elements like copper and zinc enhancing their heat resistance. Lastly, the alloy composition of aluminum sheet affects its microstructure, which in turn affects its mechanical properties. Different alloy compositions can result in different microstructures, such as grain size, grain boundaries, and phase distribution. These microstructural features can affect the strength, hardness, and fatigue resistance of the aluminum sheet. In conclusion, the alloy composition plays a crucial role in determining the mechanical properties of aluminum sheet. By carefully selecting the appropriate alloy composition, manufacturers can tailor the sheet's properties to meet specific requirements, such as strength, ductility, formability, corrosion resistance, and heat resistance.

- Q: How many atoms are in a 2.80 cm* 2.80cm*2.80cm cube of aluminum?

- 2.8cm * 2.8cm * 2.8cm= 21.95 cm^3 is volume of Aluminum present Density of Al = 2.7g/cm^3 Convert volume of aluminum into grams of Aluminum, make sure your units cancel 21.95 cm^3 * (2.7g/1 cm^3) = 59.26 g Al Next, find how many moles of Al you have. MW Al = 27g/mol 59.26/27 = 2.19 moles Al Use Avogadro's number to find number of atoms of Al - 2.19 moles Al * (6.022x10^23 atoms/1 mol Al) = 1.32x10^24 atoms Al

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: Can the aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications.

Send your message to us

Aluminum Sheets New York - Aluminum Sheet 6061 for Window and Door System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords