Aluminum Railing Profiles - Aluminum Sheet Plate Slab Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

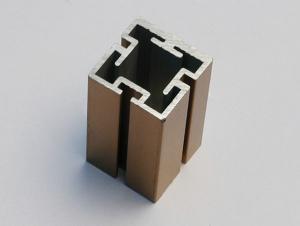

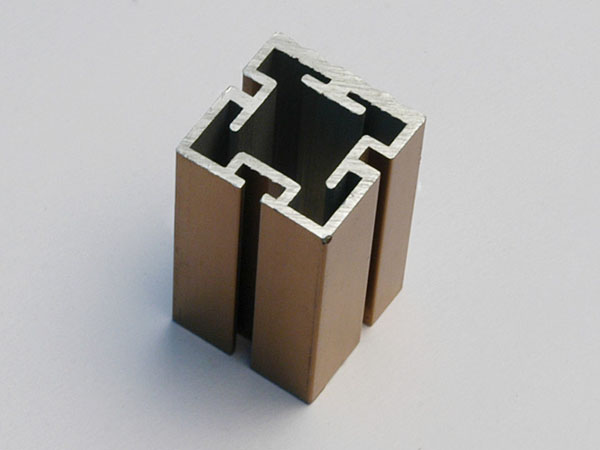

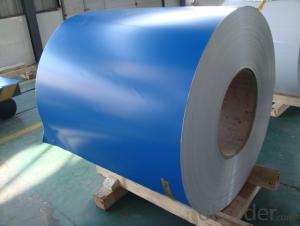

1.Structure of Product Description

Cold rolled aluminum sheet and cold rolled stainless steel plate and cold rolled stainless steel plate

are sll widely used in the field of is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,O,F, H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

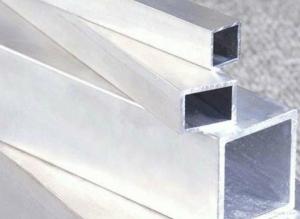

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from vietnam, sri lanka, bangladesh, etc.

ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

stainless steel sheet/plate/slab, etc

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do aluminum profiles compare to plastic profiles?

- Various industries commonly use aluminum profiles and plastic profiles for different purposes. When comparing these two materials, there are several factors that need consideration. Strength and durability are important factors to consider. Generally, aluminum profiles are stronger and more durable than plastic profiles. Aluminum possesses high tensile strength, enabling it to withstand heavy loads and resist deformation. Conversely, plastic profiles are more prone to cracking or breaking under excessive stress. Another factor to consider is weight. Aluminum profiles are heavier compared to plastic profiles. This characteristic can be advantageous or disadvantageous depending on the specific application. The weight of aluminum can provide stability and strength, while the lightweight nature of plastic makes it easier to handle and install. Corrosion resistance is also a significant aspect to examine. Aluminum profiles exhibit excellent corrosion resistance properties, enabling them to endure exposure to various environmental conditions. This makes them suitable for outdoor applications. In contrast, plastic profiles are not as resistant to certain chemicals or UV radiation, which can cause degradation over time. Flexibility and design are important considerations as well. Plastic profiles offer greater design flexibility compared to aluminum profiles. Plastic can be molded easily into complex shapes and customized to meet specific requirements. Aluminum, although less flexible, can still be shaped or extruded into different profiles within certain limitations. Thermal and electrical conductivity should also be taken into account. Aluminum profiles have superior thermal conductivity, allowing them to dissipate heat more effectively. Consequently, they are often used in applications where heat dissipation is critical, such as electronics or heat sinks. Plastic profiles, on the other hand, have lower thermal conductivity and are less suitable for such applications. Cost is another factor to consider. Generally, plastic profiles are more cost-effective than aluminum profiles. The manufacturing process for plastic profiles is simpler and cheaper, resulting in lower production costs. Conversely, aluminum profiles require more advanced manufacturing techniques and additional finishing processes, making them relatively more expensive. In conclusion, the choice between aluminum and plastic profiles depends on the specific requirements of the application. Aluminum profiles offer superior strength, durability, and corrosion resistance, making them suitable for heavy-duty or outdoor applications. On the other hand, plastic profiles provide more design flexibility and cost-effectiveness, making them ideal for lightweight or customized applications.

- Q: Can aluminum profiles be used in solar reflector systems?

- Yes, aluminum profiles can be used in solar reflector systems. Aluminum is a commonly used material in solar reflector systems due to its high reflectivity and excellent corrosion resistance. Aluminum profiles can be easily customized and shaped into various forms to optimize the reflection of sunlight onto the solar panels. Additionally, aluminum profiles are lightweight and durable, making them suitable for outdoor applications. Overall, aluminum profiles are an effective and efficient choice for solar reflector systems.

- Q: This question asks for a comparison between aluminum profiles and other materials concerning cost and availability.

- <p>Aluminum profiles are generally cost-effective and widely available compared to other materials. They are less expensive than materials like stainless steel and titanium, making them a popular choice for various applications. Aluminum is also readily available in the market due to its high demand in industries such as construction, automotive, and aerospace. Additionally, aluminum has a lower density, which means it's lighter and easier to transport and handle, further reducing costs. However, the cost and availability can vary depending on market conditions, geographical location, and specific alloy types.</p>

- Q: This question asks whether aluminum profiles can be joined using welding or bolting methods.

- <p>Yes, aluminum profiles can be both welded and bolted together. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity, but it is possible and results in a strong joint. Bolting is a common method for joining aluminum profiles, as it is quick, easy, and does not require melting the material. It is important to use appropriate hardware and techniques to ensure a secure and durable connection.</p>

- Q: What is the HS code for aluminum profile?

- There are 76072000 aluminum foil backing76081000 pure aluminum tubeTubular Aluminum Alloy 76082010.099999994 cm diameter less than or equal to 10The other 76082010.900000006 aluminum alloy outer diameter less than 10 cm.76082099.099999994 outside diameter > 10 cm, other tubular aluminium alloy76082099.900000006 outside diameter > 10 cm, other alloy aluminium tube76090000 aluminum pipe fittings76101000 aluminum doors and windows and their frames, thresholds76109000 other aluminum structures and their components76110000 volume > 300 litre aluminium bin, pot and other containers76121000 aluminium hose container76129010 aluminum cans and cansThe store, tank 76129090 volume less than 300 liters76130010 retail packaging aluminium containers for compressed and liquefied gases76130090 non retail retail containers for compressed and liquefied gases76141000 strand aluminum stranded wire, cable, braid76149000 aluminium stranded wire, cable, braid without strip core76151900.099999994 aluminum pressure cooker76151900.900000006 other household utensils such as dining table and kitchen and their aluminium appliances76152000 aluminium sanitary ware and parts76161000 aluminum nails, screws, nuts, washers and other fastenersCloth, mesh, fence and grille 76169100 aluminum wire76169910.099999994 cylindrical solid aluminum alloy with a height of less than76169910.900000006 other industrial aluminum products76169990 other non industrial aluminum products84413010 plastic aluminum composite tank production equipment84418010 make paper plastic aluminum flexible packing equipment84552290.099999994 aluminum foil roughing mill85322210 piece aluminum electrolytic capacitor85322290 other aluminum electrolytic capacitors

- Q: Are aluminum profiles suitable for cleanroom applications?

- Yes, aluminum profiles are highly suitable for cleanroom applications. Aluminum is a non-corrosive and lightweight material that is easy to clean and maintain. It offers excellent strength and structural stability, making it ideal for constructing cleanroom walls, partitions, and equipment. Additionally, aluminum profiles can be easily customized and integrated with cleanroom components such as doors, windows, and ceiling grids. Overall, aluminum profiles provide the necessary properties to meet the stringent requirements of cleanroom environments.

- Q: This question asks if aluminum profiles can be utilized in sustainable construction projects and seeks an explanation of their application.

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their durability, recyclability, and energy efficiency. Aluminum profiles are lightweight, which reduces the load on structures and can contribute to energy savings in heating and cooling. They also have high thermal conductivity, which can be beneficial for heat transfer in building systems. Additionally, aluminum is 100% recyclable, meaning it can be repurposed without losing its properties, reducing waste and the need for new raw materials. This recyclability aligns with the principles of sustainable construction by promoting a circular economy and reducing the environmental impact of building materials.</p>

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- Curvature:1. longitudinal bending: the profile is placed on the platform, and when the weight is stable, the maximum gap between the bottom of the profile and the platform is measured along the length of the profile, that is, the longitudinal curvatureThe 2. longitudinal wave degree (or bend): the section on the platform, to achieve stability by self, the ruler will be 300mm long (or flat on the surface of the profile cutter) waves or hard along the length direction of a profile, profile measurement and rule (or ruler knife) between the maximum gap value that is, longitudinal wave degree (or bend).

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Yes, aluminum profiles can be used for creating lighting fixtures. Aluminum is a popular material choice for lighting fixtures due to its lightweight nature, durability, and corrosion resistance. It is also easily shaped and machined, making it suitable for creating various designs and styles of lighting fixtures. Additionally, aluminum profiles can be powder-coated or anodized to enhance their appearance and provide additional protection against wear and tear. The versatility and aesthetic appeal of aluminum make it an ideal choice for creating lighting fixtures in a wide range of settings, including residential, commercial, and industrial applications.

- Q: Excuse me, aluminum oxidation and electrophoresis have what different?

- Main features of high-grade electrophoresis aluminum:1, with a strong film hardness, impact resistance2, with a high adhesion to the film, not easy to fall off and aging3, aluminum oxide than the more strong wear resistance, weather resistance, alkali resistance4, the surface color is rich, beautiful, has the mirror like luster effectAluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is relatively good point.

Send your message to us

Aluminum Railing Profiles - Aluminum Sheet Plate Slab Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords