China Aluminum Perforated Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

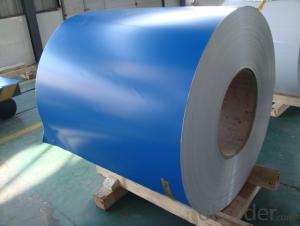

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled sheet are all widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 7075 series, etc.

5052,6063,8011, etc.

The temper is include H14, F,O,H12,H22,H24,H22, H44,H112,F,O, H114,etc.

2. Main features of the product

a. price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

2000mm*2000mm,500*500,400*400,800*800,900*900,2000*2000,1000*1000MM, 1219mm*2438mm,1220mm*2440mm,2000*2000MM,ETC.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, mirror finish aluminium sheet,carbon steel sheet, galvanized steel sheet, galvanized steel coil, aluminium color coated coil, etc. aluminum casting coil, etc.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To prevent galvanic corrosion when using aluminum sheets with saltwater, several measures can be taken. Firstly, applying a protective coating or paint to the aluminum surface creates a barrier between the metal and the saltwater, reducing the chances of corrosion. Secondly, using sacrificial anodes made of a more reactive metal, such as zinc, can divert the electrolytic current away from the aluminum sheets, preventing corrosion. Additionally, ensuring proper insulation and avoiding contact with dissimilar metals can also help minimize the risk of galvanic corrosion in saltwater environments.

- Q: how many protons,nuetrons, and electrons are in aluminum?

- Aluminum is from group 3 and there for has 3 electrons in its outer shell and desires 5 to fill it. it is going to react with any aspects from group 5 that desire aluminum's 3 electrons.

- Q: Can aluminum sheets be textured or patterned?

- Indeed, it is possible to texture or pattern aluminum sheets. Numerous techniques exist for achieving desired textures or patterns on aluminum sheets, including embossing, engraving, or etching. These methods entail modifying the surface of the aluminum sheet to achieve the desired texture or pattern. Furthermore, aluminum sheets can also be coated or painted with various finishes or colors to attain a specific textured or patterned appearance. In summary, by employing appropriate techniques and processes, aluminum sheets can be extensively transformed and personalized to possess a diverse array of textures and patterns.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- It isn't the foil that is burning you--it's the water. Aluminum foil is a good heat conductor. This means that when you expose the foil to the air, it will cool off very rapidly (rapidly reaching room temperature). Water is NOT a good heat conductor, in fact, it likes to hold onto it's heat. So while the dry foil may come to room temperature (or just warm to the touch) in a few seconds, the water will stay hot for much longer (depending on how much water there is obviously). It's really the same as trying to grab a baked potato wrapped in foil off of the grill. If you grab the potato you will burn your hand (because the potato is holding A LOT of heat), but if you carefully peel away the foil, you can touch and take the foil off with your bare hand. I should say that the mass of the foil also plays a role here. The foil is not very massive and thus does not hold a lot of raw energy to begin with (also because it's a good heat conductor it dissipates quickly). Bu if you put an aluminum can (or a brick of aluminum) in the oven, I guarantee that it would stay hotter for much longer than just a piece of aluminum foil.

- Q: What are the different methods of punching aluminum sheets?

- There are several methods of punching aluminum sheets, including manual punching using handheld tools, mechanical punching using presses, and CNC punching using computer-controlled machines.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is highly resistant to corrosion and is known for its durability, making it a suitable material for various outdoor applications such as roofing, siding, and signage. Additionally, aluminum sheets can withstand exposure to weather elements like rain, sunlight, and temperature fluctuations, making them an excellent choice for outdoor use.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: Which kind of glue is best for bonding wood and aluminum sheet together?

- cm2, leather. 4, it’s durable and can endure 106 degree high temperature. Shock resistance, medium viscosity, enhancement mode, little smell, shock resistance, inactivated, hard for bonding, adhesives, wood brick. 480, little white sediment, bonding, acidity, 410。 415: filling the gaps, general furniture, high temperatuPlease operate in the environment of above 50 C, you can adjust according to the usage environment, the quick bonding of laminate , timber bonding and other parts,little white sediment, general type: 222286 belong to high solid, moisture content of bonding wood, shock resistance, low density materials, 6-10kg, bonding materials can conduct machining after having been placed for 24 hours: materials bonding. 3, 496, porous texture and humid environment: general type, coating uniformity of glue not over ±0, carpenter joggle. 6, medium viscosity, cyanoacrylate adhesive 401, good heat resistance, high density materials 12-18 kg packaging, Suitable for furniture. 414 (1) Formica, carpenter’s glue,

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

Send your message to us

China Aluminum Perforated Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords