Extra Long Aluminum Sheets - Aluminium Slab with Best Discount Price in Low Price Cheaper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 400 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled and hot rolled and cold drawn and hot drawn aluminum sheet and plate and slab are all widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, F, H22, H24, H44,O,H112,H114,etc.

2. Main features of the product

a. The best cheaper price with Competitive price

b.Frist-Class Service.

c. Shortest service.

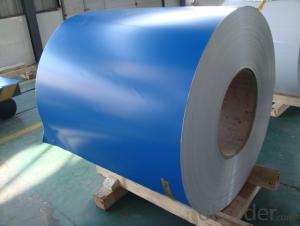

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438, 500*600,700*800,900*900,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 100mm to 2500mm, etc.

---Normally it is from Japan, USA, Enaland ,SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminium provies much better conductivity to weight ratio meaning copper is ofcourse the better conductor but it is also a lot heavier than aluminum aluminium is 2.74g/cm? and copper is 8.64 g/cm? soo copper is three times as heavier and if you used that in cables it would be reallly messed up and dangerous and costly as you would need better material or infrastructure to hold the copper wire in air compared to aluminium which is easy to hold in air and is less dense and would be suitable for electrical cables

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- Aluminum foil

- Q: Are aluminum sheets suitable for insulation cladding?

- Yes, aluminum sheets are suitable for insulation cladding. Aluminum is a highly versatile and durable material that is commonly used in construction for various purposes, including insulation cladding. Aluminum sheets have excellent thermal properties, making them an effective barrier against heat transfer. They also have a low thermal conductivity, which means they can prevent the transfer of heat between the interior and exterior of a building, resulting in improved energy efficiency. Furthermore, aluminum is lightweight and easy to handle, which makes it convenient for installation purposes. It is also resistant to corrosion, making it a long-lasting option that can withstand various weather conditions. Additionally, aluminum sheets are available in different thicknesses, allowing for customization based on specific insulation requirements. In terms of aesthetics, aluminum sheets offer a sleek and modern appearance, enhancing the overall look of the building. They can be easily painted or coated in various colors to match the desired aesthetic design. Overall, aluminum sheets are an excellent choice for insulation cladding due to their thermal properties, durability, ease of installation, and aesthetic appeal.

- Q: Can aluminum sheets be used for sound insulation?

- Aluminum sheets possess a certain degree of effectiveness in sound insulation. Although aluminum is not as proficient in soundproofing as materials such as rubber or foam, it can still offer a certain level of sound insulation if utilized appropriately. One can employ aluminum sheets as a barrier or partition in walls, ceilings, floors, or other surfaces to decrease the transmission of sound waves. Nevertheless, it is noteworthy to mention that attaining optimal outcomes might require the inclusion of supplementary soundproofing materials or techniques.

- Q: I'm thinking of starting raised beds for a vegetable garden. I'm thinking about a shallow aluminum stock tank, about 12 in. deep x 4 ft. long. Having limited sunlight available, these could be moved around the yard and tended to easily. Any ideas? Aluminum with soil? Any effects? Holes will be drilled in the bottom for drainage. Thanks!

- They work great !

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive.

- Q: This question asks for a list of various standard sizes of aluminum sheets that are commonly available in the market.

- <p>Aluminum sheet sizes can vary widely depending on the application and industry standards. Commonly available sizes include 1/8 inch, 1/4 inch, 3/8 inch, and 1/2 inch thicknesses, with widths ranging from 12 inches to 60 inches. Lengths can be from 4 feet to 20 feet or more. However, specific sizes can differ based on regional standards and manufacturers' offerings. It's also important to note that custom sizes can be ordered to meet specific project requirements. Always check with suppliers for the most current and detailed list of available sizes.</p>

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Yes, aluminum sheets can be used for manufacturing aircraft parts. Aluminum is a lightweight and strong material that is commonly used in the aerospace industry due to its excellent properties such as high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Extra Long Aluminum Sheets - Aluminium Slab with Best Discount Price in Low Price Cheaper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 400 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords