Best Workable Aluminum Sheets for Decorative Ceiling Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheet Metal Ceiling for Decoration Description:

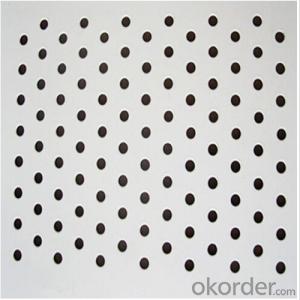

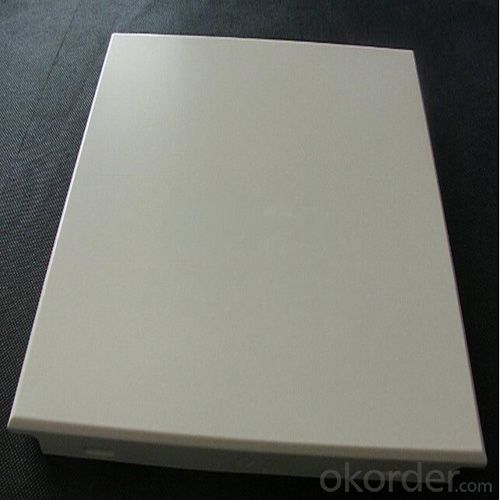

Aluminum Sheet Metal Ceiling for Decoration is in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.Perforation is a kind of processing technology for metal ceiling. ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. We have over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation .

2.Main Features of Aluminum Sheet Metal Ceiling for Decoration:

1. Product Name: Aluminum False Ceiling

2. Color: Grey, RAL color available

3. Dimension: 600 x 600mm, custom made available

4. Surface finishing: Akzo Nobel powder coating

5. Material: aluminum alloy

3. Aluminum Sheet Metal Ceiling for Decoration Images:

4. Aluminum Sheet Metal Ceiling for Decoration Specification:

| Type | Type | Thickness | Surface Coating | Size | Color |

| Aluminum Perforated False Ceiling | Aluminum Alloy | 0.8mm, Custom made availabel | Akzo Nobel Electrostatic Powder Coating | 350 X 350, 350 X 700, 600 X 600, 600 X 1200, 618 X 618, Custom made availabel | White, Custom made available |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for construction in regions with a high risk of earthquakes?

- <p>Aluminum sheets can be used in earthquake-prone areas, but their suitability depends on the specific application and construction methods. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it lacks the strength and rigidity of traditional materials like steel and concrete. When used in construction, aluminum must be properly engineered and combined with other materials to ensure structural integrity and compliance with seismic building codes. It's crucial to consult with structural engineers and follow local regulations when considering aluminum for earthquake-prone regions.</p>

- Q: Can the aluminum sheets be used for solar panel frames?

- Indeed, solar panel frames can indeed be constructed using aluminum sheets. The lightweight and robust characteristics of aluminum render it a favored material for solar panel frames. Its resistance to corrosion acts as a safeguard against rain, humidity, and UV rays, thereby shielding the frames from environmental elements. Furthermore, the recyclability of aluminum makes it an eco-friendly alternative for solar panel frames. Thanks to the adaptability and resilience of aluminum sheets, they are a fitting selection for supporting and safeguarding solar panels, guaranteeing their enduring functionality and efficiency.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- You can never ever connect an Aluminum wire to a Copper wire. Never, copper in contact with aluminum and a bit of moisture acts like a Battery. Remember the old Grade School experiment where students made a battery using copper pennies and aluminum foil by simply contacting the foil to several pennies, then lighting a neon bulb! So copper in contact with aluminum creates a galvanic action due to potential difference and thus can cause a hot spot and a fire can literally break out in the junction box where you made the connection. Keep this always in mind since you have a whole house of that aluminum wire. To connect aluminum wire to a fixture you need a fixture that will accept an aluminum wire. Check that with the hardware or where or Lowes or wherever you buy the fixture from. There are fixtues with contacts points for wire in them that accept both copper and aluminum wire. So you do not need to replace the wire just to install the fixture. Or you can go to Lowes and get a special connector that safely connects the aluminum wire to a short piece of copper wire and then connect that copper pigtail piece to any fixture you buy. The danger of aluminum wire has never been that becomes brittle, but that corrosion forms at screw joints in the switches, outlet boxes and the like, that causing a resistance and that resistance acting literally like a heater and becoming red hot and starting a fire.

- Q: Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- That's a good question, I was wondering the same thing myself

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- Aluminum okorder / So 7.50 * 22.2 * 10-6 * 89 = 0.0111555 mm diameter increase (should only report 3 sig figs, so 7.51 mm). The area is then pi / 4 * d^2 = 44.31017 (so 44.3) mm^2

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- you can answer sodium hydroxide solution, dilute acid is useless, aluminum's oxide film is very thick,as for concentration, aluminum will be passivating in concentrated sulfuric acid. if you are high school student,higher concentration is better, you can complete deoxidation by abrasive paper.

- Q: This question asks for a comparison between aluminum sheets that have undergone anodizing treatment and those that have not, highlighting their distinct characteristics.

- <p>Anodized aluminum sheets are aluminum that has been treated with an electrochemical process to increase its thickness and durability, forming a protective oxide layer on the surface. This process enhances corrosion resistance, wear resistance, and allows for a wide range of colors. Non-anodized aluminum sheets, on the other hand, have not undergone this treatment and are more prone to corrosion and less durable. They also have a more limited color range and are generally softer and less resistant to wear.</p>

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- how much did you add i mix it with the soil for my hydrangeas and never have a problem.. blend it into the soil around the hydrangeas the burning you see may be related to something other than the aluminum sulfate

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- You can use regular aluminum foil in place of heavy duty foil, but will have use 2-3 layers of the regular foil. Also be careful when wrapping the ribs in the foil that bones do not tear the foil. Heavy duty foil is also wider than regular foil so you may have to join 2 piece of regular foil together. Cut off two-there layers (4-6 pieces) of regular aluminum foil to the length you need, line the layers next to each other, then take the double or triple layers and line them up, fold over the edges 3-4 times to make a seal. The folds need only be a 1/4 - 1/2 inch.

Send your message to us

Best Workable Aluminum Sheets for Decorative Ceiling Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords