Aluminum Colors Sheets for Decorative Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Decorative Aluminum Alloy Sheets for Ceiling System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Decorative Aluminum Alloy Sheets for Ceiling System

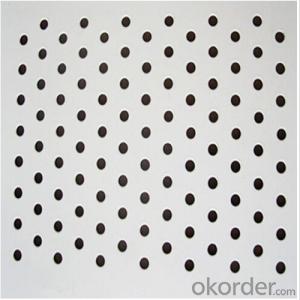

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Decorative Aluminum Alloy Sheets for Ceiling System

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

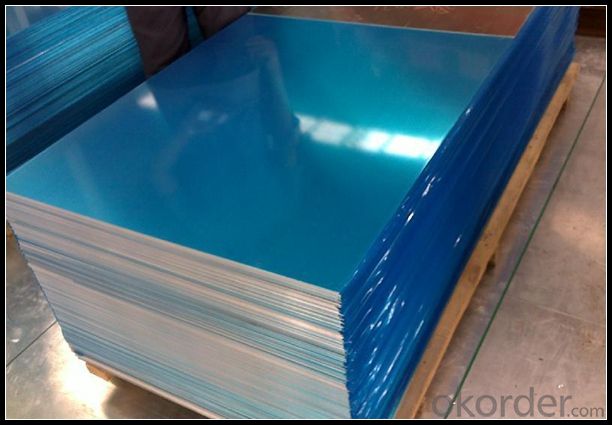

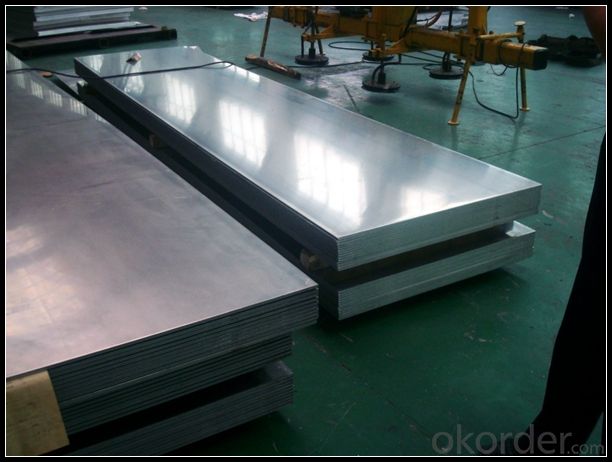

5. Image of Decorative Aluminum Alloy Sheets for Ceiling System

6. Package and shipping of Decorative Aluminum Alloy Sheets for Ceiling System

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do you ensure the dimensional accuracy of aluminum sheets?

- To achieve the desired dimensional accuracy of aluminum sheets, several actions can be taken: 1. Utilize Advanced Manufacturing Techniques: Employing state-of-the-art equipment and methodologies in the production of aluminum sheets is crucial for ensuring precise dimensions. This entails utilizing reliable and calibrated machinery to accurately cut, roll, and shape the sheets according to the specified requirements. 2. Implement a Comprehensive Quality Control System: Establishing a robust quality control system is essential for upholding dimensional accuracy. This entails conducting regular inspections and measurements at different stages of the manufacturing process to identify any deviations from the required dimensions. Precision measuring instruments, such as calipers, micrometers, or laser scanning devices, can be employed to accomplish this. 3. Opt for High-Quality Materials: The choice of aluminum material significantly impacts dimensional accuracy. Using high-quality aluminum with consistent properties and minimal impurities guarantees that the sheets maintain their desired dimensions throughout the manufacturing process. 4. Control Temperature: Temperature fluctuations can affect the dimensional accuracy of aluminum sheets due to expansion or contraction. Maintaining a controlled temperature environment during manufacturing helps mitigate these effects and ensures that the sheets retain their intended dimensions. 5. Handle and Store Properly: Exercising caution in the handling and storage of aluminum sheets is crucial to prevent any deformations or damages that could impact their dimensions. This involves utilizing appropriate lifting equipment, avoiding excessive bending or twisting, and storing the sheets in a controlled environment to shield them from moisture or extreme temperatures. 6. Regularly Calibrate Measuring Instruments: Regular calibration of measuring instruments used in the dimensional inspection process is vital. This practice ensures accurate measurements and eliminates any potential errors that may arise from instrument drift or wear. By adhering to these measures, manufacturers can minimize dimensional variations and uphold the desired accuracy of aluminum sheets, thereby meeting the specific requirements of various industries such as automotive, aerospace, construction, and electronics.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Indeed, furniture manufacturing can make effective use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers a multitude of advantages for the production of furniture. It possesses corrosion resistance, rendering it suitable for both indoor and outdoor furniture. Moreover, aluminum showcases a remarkable strength-to-weight ratio, facilitating the creation of robust and long-lasting furniture items. Additionally, aluminum proves to be easily malleable, as it can be cut, bent, and welded into various shapes and designs. Furthermore, aluminum can be treated with a diverse range of coatings or paints to enhance its visual appeal and safeguard it from damage. In summary, the strength, versatility, and aesthetic allure of aluminum sheets establish them as a viable alternative for furniture manufacturing.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a material for exterior walls in construction.

- <p>Aluminum sheets for exterior walls offer several advantages, including durability, low maintenance, and resistance to corrosion and weathering. They are lightweight, which can reduce the load on structures, and are recyclable, contributing to sustainability. Additionally, aluminum sheets can be easily shaped and painted, offering design flexibility. However, they have some disadvantages, such as being a poor insulator, which may require additional insulation for energy efficiency. They can also dent or scratch easily and may require more frequent replacement due to their lower resistance to impacts compared to materials like stone or brick. Furthermore, while they reflect heat well, they can also conduct cold, potentially leading to issues in extreme temperature conditions.</p>

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- In terms of weight, aluminum sheets are much lighter than steel sheets. The reason for this is that aluminum has a lower density, making it a more versatile and lightweight material compared to steel. The extent of the weight difference between aluminum and steel sheets will vary depending on the thickness and dimensions of the sheets. However, as a general rule, aluminum sheets can weigh approximately 1/3 less than steel sheets of the same dimensions. This quality makes aluminum sheets particularly suitable for industries like aerospace, where weight is a crucial consideration, as well as for lightweight structures.

- Q: which kind of aluminum sheet could be bended after being etched?

- general etching materials include stainless steel and copper.

- Q: How are aluminum sheets manufactured?

- Aluminum sheets are manufactured through a process called rolling. The process starts with aluminum ingots, which are heated and then passed through a series of rolling mills. These mills apply pressure to the ingots, reducing their thickness and lengthening them at the same time. As the ingots pass through the mills, they are gradually transformed into thin sheets of aluminum. The rolling mills consist of a series of rollers, which are typically made of steel. The rollers rotate in opposite directions, and as the aluminum passes between them, it is squeezed and stretched. This continuous process of rolling helps to refine the aluminum's grain structure and improve its mechanical properties. To ensure the proper thickness and surface finish, the aluminum sheets may go through multiple passes in the rolling mills. Each pass gradually reduces the thickness of the sheet until the desired thickness is achieved. The final pass also imparts the desired surface finish. After the rolling process, the aluminum sheets may undergo further treatments such as annealing or surface treatments to enhance their properties or appearance. Annealing involves heating the sheets to a specific temperature and then cooling them slowly to relieve internal stresses and improve their strength. Once the sheets are manufactured and treated, they are typically cut into desired sizes and shapes. This can be done through shearing, which involves cutting the sheets with sharp blades, or by using specialized cutting machines. Overall, the manufacturing of aluminum sheets is a complex and precise process that involves heating, rolling, and treating the aluminum to achieve the desired thickness, finish, and properties.

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed due to their malleability and ductility.

Send your message to us

Aluminum Colors Sheets for Decorative Ceiling System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords