Best Aluminum Baking Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

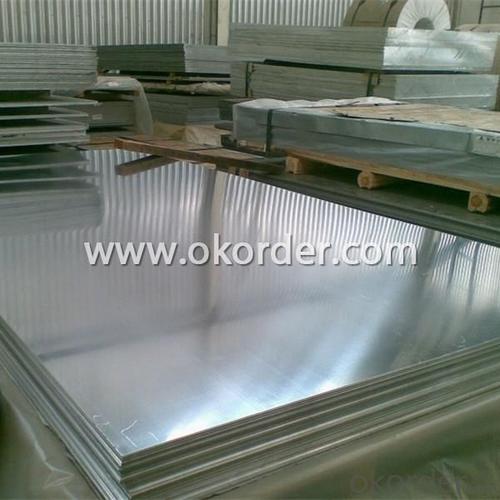

1.Structure of Aluminium Coils for Point-Fixing Curtain Walls Aluminium coils for point-fixing curtain walls are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. . Aluminium coils for point-fixing curtain walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Coils for Point-Fixing Curtain Walls •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Coils for Point-Fixing Curtain Walls Images 4.Specification of Aluminium Coils for Point-Fixing Curtain Walls Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5. FAQ A.What about inspections to guarantee quality? For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium sheets? We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets is generally lower compared to other metals such as stainless steel or copper. Aluminum is a widely available and abundant material, which contributes to its relatively affordable price in comparison to other metals.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: what's the size of aluminum sheet circle?

- aluminum sheet circle's texture 1060, 3003 thickness 0.4-5.0mm, diameter 190-760mm.

- Q: I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- 1. Crack type: longitudinal crackFeatures: by table and depthShape conditions: hardenability of the workpiece, easy to produce raw materials, carbide band segregation or non-metallic inclusions extensionPreventive measures: control raw material quality, select preheating treatment, improve original organization2. Crack type: net crackFeatures: located on the surface of the workpiece, depth 0.01 ~ 2mmSurface conditions: surface decarburization, heat treatment, surface hardening, easy to presentPrevent measures: take heating protection, avoid decarburization, delay quenching cooling, reduce quenching temperature3. Crack type: arc crackFeatures: located at the corner of the workpiece, hidden in the surface layerShape conditions: prone to Weicui through the workpiece or carburized partsPreventive measures: change workpiece design, cross section fillet rationalization4, crack type: peel crackCharacteristic: showing the delamination of hardened layerShape condition: surface hardening parts or heat treatment partsPrevention measures: reasonable choice of medium, delay cooling5. Crack type: microcrackFeatures: defects in microstructureShape conditions: hardening of high carbon martensite nearPreventive measures: avoid heating, hot, coarse grain

- Q: Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- Safely Permanently Remove Moles, Warts and Skin Blemishes

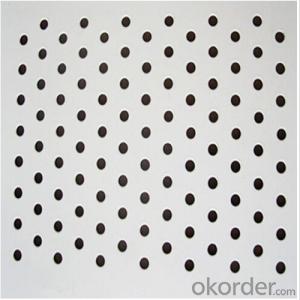

- Q: Can aluminum sheets be perforated for ventilation purposes?

- Indeed, ventilation purposes can be accomplished by perforating aluminum sheets. The process of perforating involves the creation of minute holes or designs on the sheet to facilitate the flow of air and ventilation. This method finds widespread usage in diverse industries like construction, automotive, and manufacturing. Perforated aluminum sheets provide numerous advantages for ventilation objectives, including improved air circulation, temperature regulation, and moisture management. The size, shape, and arrangement of the perforations can be tailored to meet specific ventilation needs. Furthermore, perforated aluminum sheets possess attributes such as lightness, robustness, and resistance to corrosion, rendering them highly suitable for applications that demand both ventilation and structural integrity.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- 101 aluminum sheets are not appropriate for applications involving conductive heat transfer. This specific aluminum alloy, known as 101 aluminum, is commercially pure and has a low electrical conductivity. Consequently, it is ineffective at efficiently conducting heat, rendering it unsuitable for situations requiring heat transfer. Instead, it is advisable to employ alloys with higher thermal conductivity, such as 6061 or 7075 aluminum, for conductive heat transfer applications. These alloys possess superior heat transfer properties and are commonly utilized in heat sinks, heat exchangers, and other scenarios demanding efficient heat transfer.

- Q: Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Absolutely, heat exchanger fins can indeed make use of aluminum sheets. Aluminum stands out as a favored option for heat exchanger fins owing to its remarkable thermal conductivity, lightweight attributes, and resistance to corrosion. The utilization of aluminum fins enables efficient heat transfer to take place between the fluid and its surroundings. Moreover, aluminum sheets can be effortlessly molded into diverse fin shapes and sizes, allowing for a great deal of design flexibility. All in all, aluminum sheets prove to be a fitting and frequently employed material for heat exchanger fins.

- Q: Are aluminum sheets suitable for high-temperature applications?

- No, aluminum sheets are not suitable for high-temperature applications as they have a low melting point and tend to lose their strength and become deformed at high temperatures.

Send your message to us

Best Aluminum Baking Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords