Aluminum Decorative Sheets - High Quality Aluminum Plates at Best Prices in Stock

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

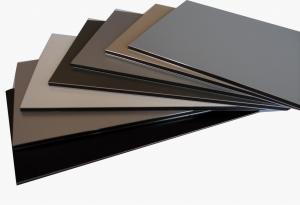

1.Structure of Product Description

Aluminium cold rolled sheet and aluminium hot rolled plate are all widely used in the field of industrial decoration field, etc.

There are many different grades, such as: 1000 series, 8000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,2024, 3003,6061,6063,8011,7075,3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 10mm to 7000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 11 tons/each size.

How many tons did you export in one year

USA, bangladesh, sri lanka,UAE,fiji,Canada, etc.

What is your mainly products?

---Normally they are checkered aluminum sheet with big-5-bar, and smal-5-bar, etc. Also mirror finish aluminium sheet,and the best-selling aluminum casting coil, etc.

- Q: How do you store aluminum sheets?

- To store aluminum sheets, it is important to consider their size, weight, and overall condition. Here are some steps you can follow: 1. Choose a suitable location: Find a dry and well-ventilated area with stable temperatures, preferably indoors. This will help prevent moisture and humidity from causing corrosion or damage to the aluminum sheets. 2. Protect against moisture: Use plastic or moisture-resistant sheets to wrap each aluminum sheet individually. This will create a barrier against moisture and prevent any potential corrosion. Avoid using materials that may react with aluminum, such as acidic or alkaline substances. 3. Organize and stack: If you have multiple aluminum sheets, consider organizing them based on their size, thickness, or other relevant factors. This will make it easier to access specific sheets without disturbing the entire stack. When stacking the sheets, place larger and heavier ones at the bottom to avoid any potential damage. 4. Utilize racks or pallets: If you have a larger quantity of aluminum sheets, using racks or pallets can provide additional support and stability. Ensure the racks or pallets are strong enough to handle the weight and are designed to prevent any deformation or bending of the sheets. 5. Label and document: It is helpful to label each sheet with relevant information such as size, thickness, or any specific details. Additionally, keeping a detailed inventory or catalog of your aluminum sheets can help you easily locate and retrieve specific ones when needed. 6. Regular inspection: Periodically inspect your stored aluminum sheets to ensure they remain in good condition. Look for signs of corrosion, damage, or any other issues that may require immediate attention. By following these steps, you can effectively store aluminum sheets, protecting them from damage and ensuring their longevity.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: Are aluminum sheets suitable for construction in regions with a high risk of earthquakes?

- <p>Aluminum sheets can be used in earthquake-prone areas, but their suitability depends on the specific application and construction methods. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it lacks the strength and rigidity of traditional materials like steel and concrete. When used in construction, aluminum must be properly engineered and combined with other materials to ensure structural integrity and compliance with seismic building codes. It's crucial to consult with structural engineers and follow local regulations when considering aluminum for earthquake-prone regions.</p>

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q: This question asks about the expected duration or service life of aluminum siding or cladding used in construction.

- <p>The lifespan of aluminum siding or cladding typically ranges from 20 to 50 years, depending on the quality of the material, installation, and environmental conditions. High-quality aluminum siding, when properly maintained and installed, can last up to 50 years. It is resistant to rust and decay, making it a durable choice for exterior cladding. However, factors such as extreme weather conditions, poor installation, and lack of maintenance can reduce its lifespan.</p>

- Q: What is the electrical conductivity of aluminum sheets?

- Aluminum sheets possess a rather high electrical conductivity, positioning aluminum as an exceptional conductor of electricity among typical metals. With an approximate conductivity rating of 37.7 x 10^6 siemens per meter (S/m), aluminum thrives as a favored selection for an array of electrical purposes, including wiring, power transmission lines, and electrical connectors.

- Q: What type of aluminum plate does it contain?

- The 3 * * * series aluminum plate is mainly composed of manganese, and the content is between 1.0-1.5%.4 * * * series aluminum sheet: stands for 4A01. The 4 * * * series aluminum plate belongs to a series with high silicon content.5 * * * series aluminum sheet: stands for 5052, 5005, 5083, 5A05 series.

- Q: The user is asking if it's possible to substitute recycled aluminum sheets for new ones in a project or application.

- <p>Yes, you can use recycled aluminum sheets instead of new ones in many applications. Recycled aluminum maintains the same properties as new aluminum, making it suitable for construction, manufacturing, and various other uses. It's also more sustainable and cost-effective. However, it's important to ensure that the recycled aluminum meets the required specifications and quality standards for your specific project to avoid any structural or performance issues.</p>

- Q: This question asks about the various patterns that can be applied to aluminum sheets, which are commonly used in construction, manufacturing, and design.

- <p>Aluminum sheet patterns are diverse and cater to various applications. Some common types include diamond, checkered, embossed, perforated, and ribbed patterns. Diamond patterns offer a classic look and are slip-resistant, while checkered patterns are often used for flooring due to their traction. Embossed patterns provide a decorative touch and can enhance surface strength. Perforated patterns are used for ventilation, light filtration, and design purposes. Ribbed patterns, also known as corrugated, offer structural strength and are used in roofing and siding applications. Each pattern serves a specific function and aesthetic, making aluminum sheets versatile for many industries.</p>

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Aluminum Decorative Sheets - High Quality Aluminum Plates at Best Prices in Stock

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords