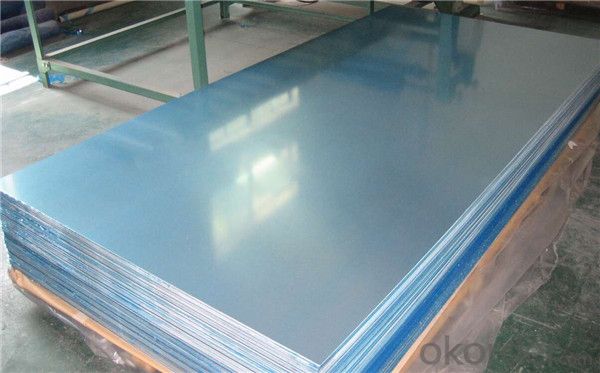

Aluminum Step Tile Roofing Sheets 1050 3003 1060 1100 1.2mm 3mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

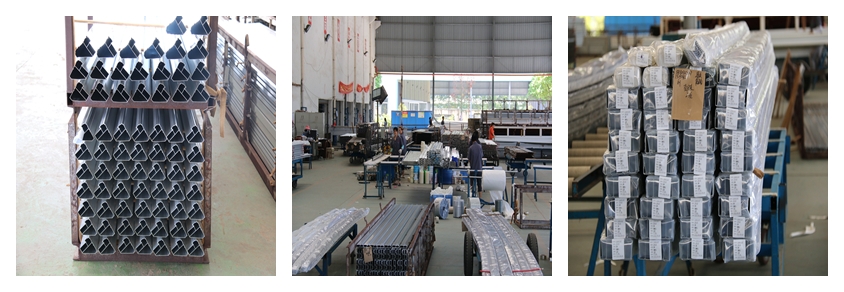

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is lightweight, resistant to corrosion, and can be easily shaped into cans. It also provides a protective barrier against light and air, ensuring the quality and freshness of the beverages inside.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- no that wouldn't make you sick. i line all my pans with foil before baking because it makes it much easier to clean the pans.

- Q: Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight nature, durability, and corrosion resistance. Aluminum sheets can be easily formed into various shapes and sizes, making them suitable for creating the structural frame of curtain walls. Additionally, aluminum can be coated or anodized to enhance its aesthetic appeal and provide additional protection against weather elements. This makes aluminum sheets a versatile and practical material for constructing curtain walls in commercial and residential buildings.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Indeed, the utilization of aluminum sheets in the manufacturing of food packaging is feasible. Owing to its diverse characteristics, aluminum has become a favored option for food packaging. Its lightweight nature, resistance to corrosion, and exceptional heat conductivity are among the reasons for this preference. These attributes render it suitable for safeguarding the freshness and quality of food items. Moreover, aluminum possesses impermeability to light, moisture, and oxygen, thereby aiding in the extension of the shelf life of food products. Furthermore, the malleability of aluminum sheets enables them to be effortlessly molded into various shapes and sizes, thus facilitating tailored packaging solutions. In essence, the food packaging industry frequently relies on aluminum sheets due to their adaptability, durability, and their ability to ensure the safety and integrity of food items.

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination involves bonding a layer of material, such as plastic or paper, to the surface of the aluminum sheet to provide protection, enhance aesthetics, or improve functionality.

- Q: This question asks about the various types of aluminum sheets that are suitable for use in exterior applications, specifically those that can withstand outdoor conditions.

- <p>Aluminum sheets used for exterior applications come in various types, each with specific properties to withstand weather and environmental conditions. These include: 1. Mill Finish Aluminum Sheets: These have a natural aluminum finish and are used for applications requiring a raw, industrial look. 2. Anodized Aluminum Sheets: These are aluminum sheets that have been treated to increase their resistance to corrosion and wear. 3. Painted Aluminum Sheets: These are coated with a layer of paint for added protection and aesthetic appeal. 4. Embossed Aluminum Sheets: These have a textured surface and are used for decorative purposes or to provide a non-slip surface. 5. Perforated Aluminum Sheets: These are aluminum sheets with holes punched through them, used for ventilation or decorative purposes. Each type is chosen based on the specific requirements of the exterior application, such as durability, aesthetics, and environmental resistance.</p>

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is a versatile and lightweight material that offers several benefits for modular construction projects. It is durable, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for various structural applications. Aluminum sheets can be easily fabricated and formed into different shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable construction practices. Overall, aluminum sheets are a viable option for modular construction due to their strength, durability, and versatility.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

Send your message to us

Aluminum Step Tile Roofing Sheets 1050 3003 1060 1100 1.2mm 3mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords