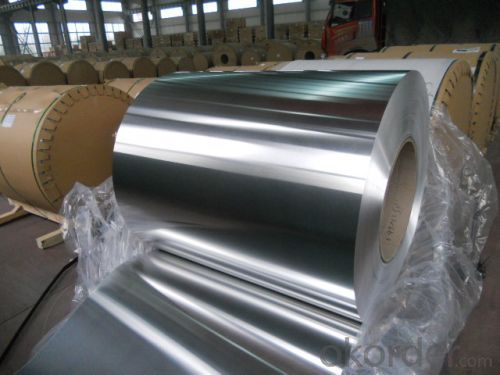

Aluminum Sheet 1050 3003 1.2Mm 3Mm 6Mm 1.15Mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

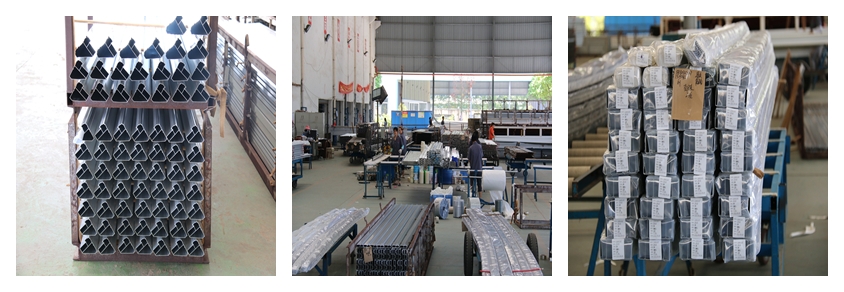

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight and durable material that is commonly used in the construction of bus bodies. Its high strength-to-weight ratio makes it an ideal choice for bus manufacturers, as it allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, which is beneficial for vehicles that are constantly exposed to various weather conditions. Moreover, aluminum can be easily formed and fabricated, allowing for the creation of complex shapes and designs. Overall, aluminum sheets are a popular choice for bus bodies due to their strength, lightness, corrosion resistance, and versatility.

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the manufacturing process and desired application. Common surface finishes for 101 aluminum sheets include mill finish, brushed finish, and polished finish.

- Q: Can aluminum sheets be soldered?

- No, aluminum sheets cannot be soldered using traditional soldering methods. However, alternative techniques such as specialized soldering alloys, fluxes, or adhesives can be used to join aluminum sheets together.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

- Q: Are aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is known for its excellent resistance to corrosion, even in harsh outdoor environments. It is lightweight, durable, and can withstand various weather conditions, making it an ideal choice for outdoor applications such as roofing, siding, and decorative elements.

- Q: What does 1060h/24 mean in aluminium alloy?

- Each digit in the 1060-H24 stands for the following meanings:First, a number of Arabia 1 is representative of pure aluminum (aluminum is aluminum content above 99% aluminum, in addition to the beginning and start with 2-8 are 2### for copper and aluminum magnesium alloy, 3### aluminum manganese alloy, 4### alloy, 5### alloy and so on)Two, second, Arabia number 0, said the original alloy, such as 1, said the original alloy after a modification, 2 means that the original alloy after two modificationsThree, third and four 60 two Arabia data represent the value behind pure aluminum content of 99% per cent in pure aluminum, said 60 pure aluminum aluminum content of 99.60%, as the standard 1050 indicates the aluminum content of pure aluminum, 99.50% of the 1070 said that the aluminum content of 99.70% pure aluminum alloy in the back.

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to take certain safety precautions. These include wearing personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust particles. Additionally, using appropriate tools and machinery specifically designed for handling aluminum sheets is essential to prevent accidents or injuries. Finally, proper handling and storage of aluminum sheets, ensuring they are stacked securely and avoiding any sharp edges, can help minimize the risk of accidents or damage.

Send your message to us

Aluminum Sheet 1050 3003 1.2Mm 3Mm 6Mm 1.15Mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords