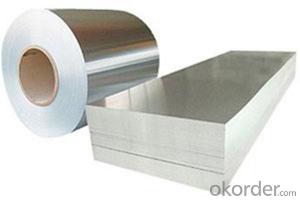

Red Aluminum Foil Sheets 1050 1070 1100 3003 1.2mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

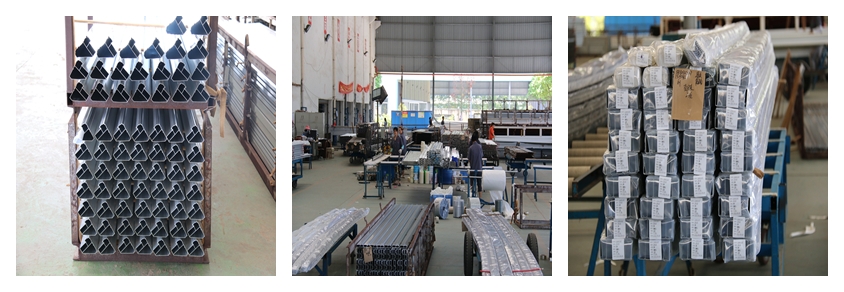

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Yes, aluminum sheets are highly suitable for manufacturing lightweight structures due to their low density and high strength-to-weight ratio.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: Can 101 aluminum sheets be used for roofing or siding?

- Indeed, one can utilize 101 aluminum sheets for either roofing or siding purposes. Aluminum, renowned for its robustness, lightweight composition, and ability to resist corrosion, remains a favored material for both roofing and siding applications. Opting for aluminum sheets as a roofing or siding solution guarantees a durable outcome, capable of enduring adverse weather conditions with minimum upkeep. What's more, aluminum sheets are accessible in several thickness options, including 101, thereby providing flexibility to accommodate diverse design and structural requirements.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Yes, 101 aluminum sheets are generally easy to work with in terms of cutting, drilling, and shaping. Aluminum is known for its lightweight and malleable properties, making it more manageable compared to other metals. The 101 aluminum alloy specifically offers good formability and weldability, making it suitable for various fabrication processes. When it comes to cutting, aluminum sheets can be easily cut using common tools such as a saw, shears, or even a simple utility knife. Similarly, drilling holes in aluminum sheets is relatively easy and can be done with standard drill bits. Lastly, shaping aluminum sheets can be achieved through bending, folding, or using specialized tools like a brake press. However, it's always important to use appropriate safety measures and equipment when working with any metal, including aluminum.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: Are aluminum sheets suitable for bulletproof applications?

- Aluminum sheets are not traditionally considered suitable for bulletproof applications due to their relatively low strength and density compared to other materials commonly used for bulletproofing, such as steel or ballistic ceramics. While aluminum does exhibit good resistance to corrosion and has a high strength-to-weight ratio, it lacks the necessary hardness and toughness required to effectively stop or slow down bullets. In contrast, materials like steel or ballistic ceramics have superior properties that enable them to withstand the impact of ballistic projectiles. Steel, for example, possesses high hardness and strength, making it capable of absorbing and dispersing the energy from a bullet upon impact. Ceramic materials, on the other hand, have high compressive strength and hardness, allowing them to shatter and absorb the energy of a bullet, effectively preventing penetration. To summarize, while aluminum sheets may serve various purposes due to their corrosion resistance and lightweight nature, they are generally not suitable for bulletproof applications. For effective protection against ballistic threats, it is advisable to consider materials specifically designed and engineered for such purposes, like steel or ballistic ceramics.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is a widely used material in the electronics industry due to its excellent conductivity, low weight, and high durability. It is commonly used for various applications such as housing for electronic components, heat sinks, and electrical connectors. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of electronic devices. Additionally, aluminum is a cost-effective material, making it an attractive choice for manufacturers in the electronics industry.

Send your message to us

Red Aluminum Foil Sheets 1050 1070 1100 3003 1.2mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords