Home Depot Decorative Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 1.2mm 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

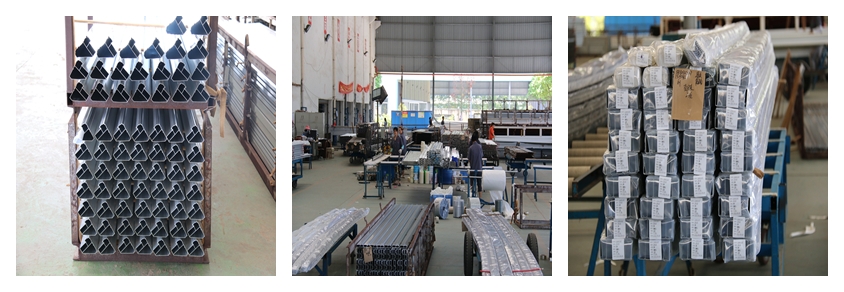

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

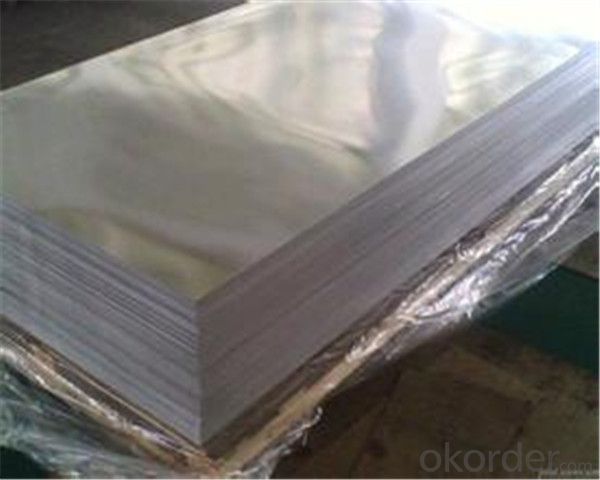

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What are the various color and pattern options for aluminum sheets?

- <p>Aluminum sheets are available in a wide range of colors and patterns to suit various applications and aesthetic preferences. Colors can include silver, white, black, bronze, and many other shades. Patterns can range from simple matte or gloss finishes to more complex textures like wood grain, stone, and brushed metal effects. Some aluminum sheets also feature anodized finishes for enhanced durability and color vibrancy. Custom colors and patterns can be created through specialized coating processes, allowing for a high level of personalization in design and construction projects.</p>

- Q: How do you ensure the surface quality of aluminum sheets?

- To ensure the surface quality of aluminum sheets, several measures can be taken: 1. Cleaning: Before any surface treatment or inspection, it is essential to thoroughly clean the aluminum sheets to remove any dirt, grease, or other contaminants. This can be done with solvents, detergents, or specialized cleaning agents. 2. Visual Inspection: Conduct a visual inspection of the surface for any visible defects like scratches, dents, or pitting. This can be done by trained personnel using proper lighting and magnification tools. 3. Chemical Treatment: Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments like anodizing, chromate conversion coating, or passivation. These processes can enhance the surface quality, corrosion resistance, and aesthetic appearance of the sheets. 4. Mechanical Polishing: Mechanical polishing techniques such as grinding, buffing, or sanding can be employed to remove surface imperfections and achieve a smooth, glossy finish. Care should be taken to ensure consistency and avoid over-polishing, which can compromise the sheet's integrity. 5. Coating and Protecting: Applying protective coatings like lacquers, paints, or powder coatings can further enhance the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality Control: Implementing rigorous quality control procedures throughout the manufacturing process is crucial. This includes regular inspections, testing, and documentation to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Handling and Packaging: Proper handling and packaging during transportation and storage are essential to prevent any surface damage. Adequate protective measures such as using protective films, paper interleaves, or cushioning materials can be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure the surface quality of aluminum sheets, meeting the desired specifications and customer expectations.

- Q: A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- Mg-Al + HCl -- MgCl2 + AlCl3 + H2 345ml gas collected over water vp water = 30torr total pressure - 30torr = pressure H2gas = 722torr = 0.95atm volume dry gas x 0.95atm = 345ml x 0.989atm volume dry gas = 359.3ml moles gas = pv/(rt) = 0.013moles 2Mg + 3Al + 10HCl -- 2MgCl2 + 2AlCl3 + 5H2 a) moles H2 = xgMg / 24.3g/mole x (5 H2 / 2Mg) = 0.103x b) moles H2 = ygAl / 27g/mole x (5H2 / 3Al) = 0.062y

- Q: Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are suitable for signage and advertising. They are durable, weather-resistant, and can be easily customized with graphics and text. Additionally, their sleek and professional appearance makes them an excellent choice for promotional materials, outdoor signs, and indoor displays.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and durable material that has excellent corrosion resistance properties, making it suitable for ventilation applications. It can be easily formed and fabricated into various shapes and sizes, allowing for the customization of ventilation components. Additionally, aluminum is a good conductor of heat, which can be beneficial for HVAC systems that require efficient heat transfer.

- Q: How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- Chaoyang aluminum manufacturers tell you that you can ask the manufacturer to cover the aluminum plate surface, to prevent aluminum plate scraping it!

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet can be measured using various methods. One common technique is to use a micrometer or caliper, which are precision measuring tools. The micrometer is placed on one end of the sheet and slowly closed until it touches the other end, providing an accurate measurement of the thickness. This method is effective for measuring thin aluminum sheets. For thicker sheets, a thickness gauge can be used. It consists of a small handheld device with a probe that is pressed against the sheet's surface. The gauge then displays the thickness reading on a screen. This method is especially useful for measuring thicker sheets where a micrometer or caliper may not be suitable. Another way to measure the thickness of an aluminum sheet is by using an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are then reflected back from the sheet's surface. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with high accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. In summary, the thickness of an aluminum sheet can be measured using various tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Q: I'm was thinking of buying an aluminium bike but I saw some good bikes with hi-ten.

- Get an aluminum frame Hi-ten steel is the buzz word for cheap plain steel.

- Q: What are the acoustic properties of aluminum sheets?

- Aluminum sheets possess several acoustic properties that make them suitable for various applications. Firstly, aluminum is a lightweight material, which means it has a high strength-to-weight ratio. This property allows aluminum sheets to vibrate easily when struck, resulting in good sound transmission. Additionally, aluminum has a low density, which means it can absorb sound energy and reduce noise levels. Moreover, aluminum sheets have excellent corrosion resistance, which ensures their durability and longevity in different environments. This property is particularly important in applications where acoustic performance needs to be maintained over time, such as in construction or automotive industries. Furthermore, aluminum exhibits good thermal conductivity, which allows for efficient heat dissipation. This property is beneficial in applications where heat generated by sound sources needs to be dispersed effectively, preventing any potential damage or degradation of the material. Overall, the acoustic properties of aluminum sheets, including their lightweight nature, sound transmission, noise reduction capabilities, corrosion resistance, and thermal conductivity, make them a versatile and reliable choice for various acoustic applications.

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- Whether that weld will be OK depends on the diameter of the cylinder. The force on the weld will be equal to the operating pressure time the radius of the cylinder, with the wall opposite the weld have an equal force. Divide that force by the thickness of the weld to figure the stress. You want to have a safety factor of about 3. As the Bernzomatic has either a brass or aluminum head, which would melt at the temperatures which are required for true welding (melting metals so that they flow together), you will be performing brazing with a Bernzomatic. I cannot comment on the strength of the brazing bond. The thickness of the brazing metal deposit depends on the strength of the brazing alloy, which I also cannot comment on. 6061 will melt at 1206°, which you will not approach with the Bernzo kit. A blowout of a metal cylinder at 60 psi could be pretty ugly. I suggest that you befriend someone who has a TIG welder and get their help. A properly welded 1/8 thick cylinder could handle about 660 psi with no problem. If you create a lap joint, using an outer strip of aluminum, and then band your cylinder with stainless steel hose clamps, you will be relying upon the brazing only to provide a gas seal. The strength would come from the hose clamps. You still need to do some calculation on forces involved. A 1/2 wide stainless hose clamp will probably hold back about 240 lb. of force with a comfortable margin of safety.

Send your message to us

Home Depot Decorative Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 1.2mm 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords