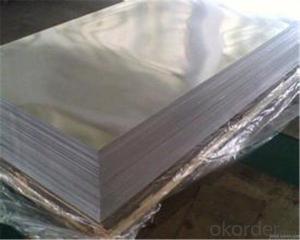

Aluminum Sheet 1050 1060 1100 1.2Mm 3Mm 6Mm 2Mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

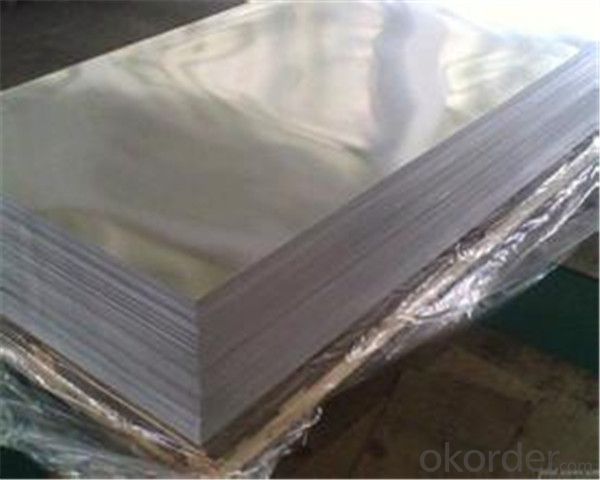

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

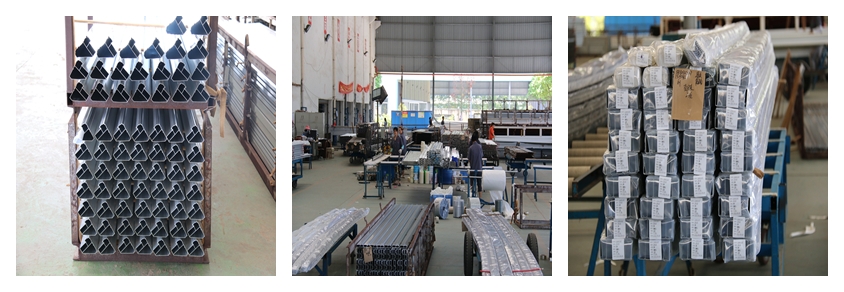

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: How do you ensure the dimensional accuracy of aluminum sheets?

- To achieve the desired dimensional accuracy of aluminum sheets, several actions can be taken: 1. Utilize Advanced Manufacturing Techniques: Employing state-of-the-art equipment and methodologies in the production of aluminum sheets is crucial for ensuring precise dimensions. This entails utilizing reliable and calibrated machinery to accurately cut, roll, and shape the sheets according to the specified requirements. 2. Implement a Comprehensive Quality Control System: Establishing a robust quality control system is essential for upholding dimensional accuracy. This entails conducting regular inspections and measurements at different stages of the manufacturing process to identify any deviations from the required dimensions. Precision measuring instruments, such as calipers, micrometers, or laser scanning devices, can be employed to accomplish this. 3. Opt for High-Quality Materials: The choice of aluminum material significantly impacts dimensional accuracy. Using high-quality aluminum with consistent properties and minimal impurities guarantees that the sheets maintain their desired dimensions throughout the manufacturing process. 4. Control Temperature: Temperature fluctuations can affect the dimensional accuracy of aluminum sheets due to expansion or contraction. Maintaining a controlled temperature environment during manufacturing helps mitigate these effects and ensures that the sheets retain their intended dimensions. 5. Handle and Store Properly: Exercising caution in the handling and storage of aluminum sheets is crucial to prevent any deformations or damages that could impact their dimensions. This involves utilizing appropriate lifting equipment, avoiding excessive bending or twisting, and storing the sheets in a controlled environment to shield them from moisture or extreme temperatures. 6. Regularly Calibrate Measuring Instruments: Regular calibration of measuring instruments used in the dimensional inspection process is vital. This practice ensures accurate measurements and eliminates any potential errors that may arise from instrument drift or wear. By adhering to these measures, manufacturers can minimize dimensional variations and uphold the desired accuracy of aluminum sheets, thereby meeting the specific requirements of various industries such as automotive, aerospace, construction, and electronics.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- All of the earlier answers are correct and the first one is very good but nobody mentioned the fact that aluminium does not have much tensile strength, and that as a result of this, some high voltage aluminium cables have a steel cable in the centre to give them the required tensile strength. Aluminium bus-bars are very popular in low voltage work because they do not need to be flexible or possess much tensile strength but yet provide the benefits of being light and cheap.

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- First look at tolerance taggingIf there is no tolerance, see the accuracy level of the workpiece and check the tolerance listA 3-4 mm deviation is acceptable if the magnitude is not noted and is of no importanceThat is, the 34mm can also be used if lower precision sizes can be addedOnly board class is generally down bias, there is very little difference

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can tolerate relies on various factors, including the composition of the alloy, thickness, and intended purpose. Generally, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, aluminum sheets can typically endure significantly higher temperatures without melting or distorting. Regarding most commercially available aluminum alloys, the maximum temperature for continuous utilization varies from 200 to 300 degrees Celsius (390 to 570 degrees Fahrenheit). Beyond this range, the material might begin to display reduced strength and heightened vulnerability to deformation or harm. Nevertheless, it is crucial to mention that the precise maximum temperature limit for a specific aluminum sheet should be determined by referring to the manufacturer's specifications or conducting specific testing. Factors like the presence of coatings or surface treatments, exposure to prolonged heat, and thermal cycling can also influence the maximum temperature tolerance of aluminum sheets.

- Q: Can 101 aluminum sheets be CNC machined?

- Yes, 101 aluminum sheets can be CNC machined.

- Q: Are aluminum sheets suitable for food-grade applications?

- Yes, aluminum sheets are suitable for food-grade applications. Aluminum is a non-toxic and non-reactive metal, making it safe for direct contact with food. It is also lightweight, durable, and resistant to corrosion, making it an ideal choice for various food-related uses such as packaging, cooking utensils, and food processing equipment.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: Are 101 aluminum sheets suitable for heat exchangers?

- 101 aluminum sheets are not appropriate for heat exchangers. Heat exchangers necessitate materials that possess commendable thermal conductivity and corrosion resistance. Although aluminum is an adept heat conductor, the 101 aluminum alloy lacks the essential corrosion-resistant properties essential for heat exchangers. Heat exchangers often employ other aluminum alloys, such as 3003 or 5052, due to their superb thermal conductivity and corrosion resistance.

Send your message to us

Aluminum Sheet 1050 1060 1100 1.2Mm 3Mm 6Mm 2Mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords