Wholesale Painted Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

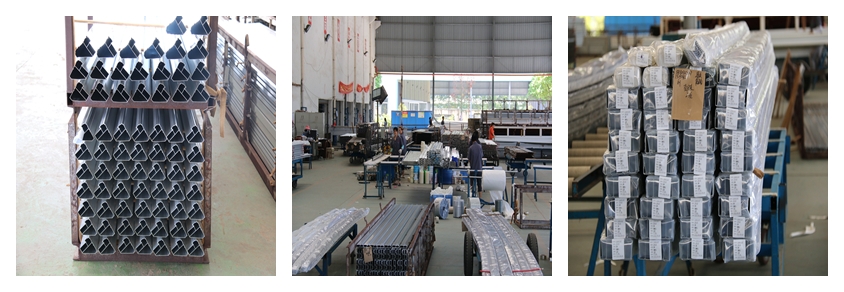

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Are aluminum sheets suitable for use in automotive or aerospace industries?

- Aluminum sheets are indeed appropriate for utilization in both the automotive and aerospace sectors. Aluminum, being a lightweight yet robust material, is perfect for applications necessitating weight reduction, particularly in the aerospace domain where fuel efficiency holds paramount importance. Moreover, aluminum possesses commendable corrosion resistance qualities, a crucial attribute for both industries due to their exposure to diverse environmental conditions. Additionally, the malleability of aluminum permits effortless fabrication and forming, rendering it adaptable for a plethora of automotive and aerospace components. Finally, when compared to alternative materials, aluminum proves to be a cost-effective option, hence its popularity in these particular industries.

- Q: This question asks for the cost of an aluminum sheet.

- <p>The cost of aluminum sheets can vary significantly based on factors such as thickness, grade, surface finish, and market conditions. As of my last update, the price range for aluminum sheets could be anywhere from $0.50 to $5 per pound, but this is subject to change. For the most accurate and current pricing, it's best to check with suppliers or on metal exchange platforms, as prices can fluctuate daily. Always consider the specific requirements of your project to determine the exact type and grade of aluminum needed, which will also affect the cost.</p>

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: Are aluminum sheets resistant to UV radiation?

- Generally, aluminum sheets are resistant to UV radiation. Aluminum is well-known for its exceptional resistance to corrosion, which also applies to its resistance to UV radiation. The naturally formed oxide layer on the surface of aluminum acts as a shield, safeguarding it against the harmful effects of UV rays. This protective layer ensures that the aluminum does not deteriorate or fade when exposed to sunlight or other UV radiation sources. Nevertheless, it is worth noting that prolonged exposure to intense UV radiation may eventually cause some degradation or discoloration of the aluminum surface. Hence, while aluminum sheets are highly resistant to UV radiation, it is advisable to provide additional protection, such as coatings or paint, for applications that involve extended exposure to harsh UV environments.

- Q: Are aluminum sheets resistant to UV rays?

- Aluminum sheets, in general, exhibit resistance to UV rays. The reason lies in the formation of a protective oxide layer on aluminum's surface, which acts as a shield against UV radiation. By doing so, this oxide layer prevents the aluminum from deteriorating or corroding when exposed to sunlight. Nevertheless, it is worth mentioning that extended exposure to intense UV radiation may lead to gradual color fading or discoloration. To further fortify the UV resistance of aluminum sheets, one can apply protective coatings or paints, which add an extra layer of defense against UV rays.

- Q: Is it possible to incorporate recycled aluminum windows into a construction or renovation project?

- <p>Yes, you can use recycled aluminum windows in your project. Recycled aluminum windows are not only environmentally friendly but also offer similar performance to new aluminum windows. They are durable, lightweight, and maintain good thermal efficiency. When selecting recycled aluminum windows, ensure they meet the required quality standards and are suitable for your project's specifications. It's also important to consider the condition of the windows and any necessary refurbishment or maintenance they might require.</p>

- Q: What are the aluminum plates for?

- Defense (cover containing polyethylene moistureproof layer of kraft paper embossing aluminum alloy), special mould. The tensile aluminum alloy aluminum coated aluminum. Special stamping. Electronic gasket aluminum, alloy aluminum alloy electric radiator. Special aluminum curtain wall coating. (fluorocarbon, polyester) aluminum coil, aluminum coil, special signs aluminum plate, color coated aluminum sheet, aluminum ceiling coating, aluminum plate, aluminum plate pattern, embossing aluminum / aluminum (pointer type, orange peel pattern, diamond, five ribs, aluminum strip). Aluminum wire and cable, transformer Using aluminum strip, aluminum foil, pressure type aluminum corrugated corrugated aluminum plate. Color coating, special aluminum plate, aluminum plate cable tray, material: 1100.1200.1050A.1060.1070.1080.1145.2A11.3003.3A21.3004.3005.3104.3105.LF21.5A02.5A05.5005.5754.5052.5083.5082.5A03.6061.6063.6082.8011. material; H111.H112.H18.H26.H16.H22.H32.H34.H36.H14.H24.H12.T4.T5.T6.O.F state can meet the requirements of customers

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

Send your message to us

Wholesale Painted Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords