Aluminum Plate Sheets - Checked Embossed Anti-Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

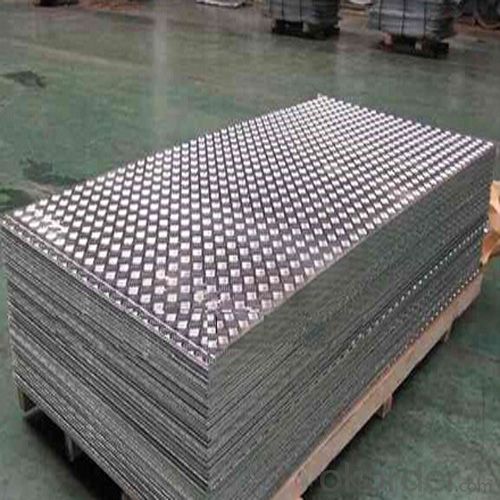

1.Structure of Checked Embossed Aluminium Plate for Antiskid Plate Description:

The aluminum embossed sheets are used in many places, transportation, decoration, construction, Packing and so on.The main products of our company are aluminium sheet, coil, aluminium embossed sheet, aluminium foil and aluminium circle. Aluminium embossed sheets include stucco embossed aluminium sheet, five-bars embossed aluminium sheet, diamond embossed aluminium sheet, etc. They are widely used in daily life.

2.Main Features of Checked Embossed Aluminium Plate for Antiskid Plate:

Aluminum Alloy Grade: 1050 1060 1100 3003 5052

Temper: H12, H14, H18, H22, H24, H26

Thickness: 0.8mm~5.0mm

Thickness tolerance: +/-0.01-0.04mm

3.Checked Embossed Aluminium Plate for Antiskid Plate Images:

4. Checked Embossed Aluminium Plate for Antiskid Plate Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1 | 0.1-0.4 | - | <0.05 | <0.05 | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | </=0.4 | 0.4 | </=0.1 | 0.4-1.0 | 4.0-4.9 | 0.25 | </=0.15 | R |

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can 101 aluminum sheets be used in the production of solar reflectors?

- Yes, 101 aluminum sheets can be used in the production of solar reflectors.

- Q: What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- To ensure the durability and longevity of outdoor aluminum sheets, there are several methods available for surface protection. These methods offer varying advantages and limitations, and the choice should be based on factors such as durability, appearance, cost, and maintenance requirements. One common method is anodizing, which creates a protective oxide layer on the surface. This increases resistance to corrosion, abrasion, and UV rays, while also providing a range of colors and finishes. Another option is powder coating, where a dry powder is applied to the aluminum sheet and baked to create a hard, protective coating. This method offers excellent resistance to weathering, corrosion, and chemicals, and is available in various colors and finishes. Paint coating is another effective method, creating a barrier between the aluminum surface and the environment to prevent corrosion while enhancing aesthetics. It is important to use high-quality paint specifically designed for aluminum to ensure proper adhesion and durability. For those looking to protect the natural appearance of aluminum, clear coating is an option. It provides a layer of protection against corrosion, oxidation, and UV rays and is often applied after anodizing or polishing. Laminating involves adhering a protective film or sheet onto the aluminum surface, offering excellent resistance to scratches, abrasion, and UV rays. This method is commonly used in applications with heavy wear and tear. Chemical conversion coatings, such as chromate conversion coating or phosphating, can be used to improve the corrosion resistance of aluminum sheets. These coatings chemically react with the surface to create a protective layer that inhibits corrosion. When choosing a method of surface protection, it is crucial to consider specific requirements and environmental conditions. Each method has its own advantages and limitations, so careful consideration is needed to ensure the best choice for the aluminum sheet's needs.

- Q: What are the different methods of surface cleaning for aluminum sheets?

- Aluminum sheets can be cleaned using various methods, each with its own advantages and suitability for different cleaning needs. One method is mechanical cleaning, which involves using techniques like brushes, abrasive pads, sandpaper, or a wire brush to remove dirt, stains, and oxidation from the surface. However, caution must be taken to avoid scratching the surface. Chemical cleaning, on the other hand, utilizes specific cleaning agents or solutions designed to dissolve or remove dirt, grease, oil, or other contaminants from aluminum surfaces. The choice of cleaning agent depends on the type of dirt or stain to be removed. High-pressure water cleaning is a method that employs a strong water jet to dislodge dirt or grime from the aluminum surface. It works well for removing loose debris or light dirt from larger areas, but may not be effective for heavily soiled surfaces. Steam cleaning involves using high-temperature steam to loosen dirt, grime, or other contaminants, making them easier to wipe or rinse away. It is versatile and suitable for both small and large surfaces. Another specialized method is electrolytic cleaning, which uses an electric current to remove contaminants. The aluminum sheet is immersed in a cleaning solution, and the electric current attracts the contaminants to a sacrificial electrode, leaving the sheet clean. However, this method requires specialized equipment and expertise. When choosing the appropriate cleaning method, it is important to consider the specific requirements, condition of the sheet, and desired level of cleanliness. Testing the chosen method on a small, inconspicuous area is also advisable to avoid potential damage.

- Q: Nissan A1100P aluminum plate is equivalent to what brand of domestic, where there are relevant information and instructions, mechanical design manuals or other materials manuals? Thank you.

- Other process properties are basically the same as those of 1050A. 1100 commonly used to have good machining performance, high corrosion resistance, high strength does not need not see, such as video and chemical handling and storage equipment, sheet metal products, hardware, hollow spinning drawing goods welding key combination, reflector, nameplate.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: What does 3003-O aluminum mean?

- 3003 is a kind of AL-SI alloy of Al Mn alloyThere are four basic states of aluminum alloys:F--Free the condition of a product after a normal working procedure requires no special heat treatment or hardening, and the mechanical properties are not limited.H-- strain hardening statusO-- annealed state (the softest of all States)T-- heat treatment status

- Q: What are the advantages of using aluminum sheets in automotive applications?

- There are several advantages of using aluminum sheets in automotive applications. Firstly, aluminum is lightweight, which helps improve fuel efficiency and overall vehicle performance. Secondly, aluminum has high strength-to-weight ratio, making it durable and resistant to corrosion. This ensures a longer lifespan for automotive components made from aluminum sheets. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice. Lastly, aluminum sheets can be easily formed and molded into complex shapes, allowing for greater design flexibility in automotive manufacturing.

- Q: Are the aluminum sheets corrosion-resistant?

- Indeed, aluminum sheets exhibit resistance to corrosion. When aluminum is exposed to oxygen, a protective oxide layer naturally develops, effectively inhibiting corrosion. This oxide layer acts as a shield, separating the aluminum from its surroundings and granting the sheets exceptional resistance against corrosion. Moreover, aluminum sheets can undergo additional treatments such as coatings or anodizing processes, further amplifying their resistance to corrosion. Consequently, aluminum sheets are widely favored for applications where the necessity for corrosion resistance is paramount.

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Aluminum sheets have the capability to undergo anodization in order to enhance their resistance to corrosion. Anodizing, an electrochemical process, is utilized to generate a protective oxide layer on the surface of the aluminum. This oxide layer effectively shields the aluminum from corrosion and deterioration. Throughout the anodization process, the aluminum sheet is immersed in an electrolyte bath and an electric current is applied. As a result, the aluminum bonds with oxygen ions, forming a dense and substantial aluminum oxide layer on the surface. This oxide layer acts as a barrier, preventing moisture and other harmful substances from reaching the underlying metal. Anodized aluminum sheets possess improved strength, extended lifespan, and heightened resistance to corrosion, making them highly suitable for a wide range of applications such as architecture, automotive manufacturing, and aerospace industries. Furthermore, anodized aluminum sheets can be dyed in numerous colors, offering not only enhanced corrosion resistance but also aesthetic appeal.

Send your message to us

Aluminum Plate Sheets - Checked Embossed Anti-Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords