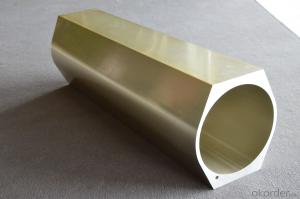

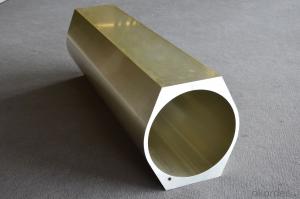

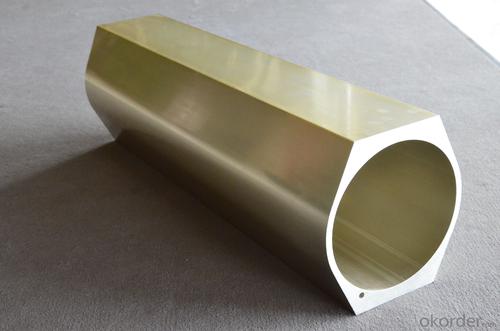

Aluminum Extrusion Channel Profiles - Aluminum Profile 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

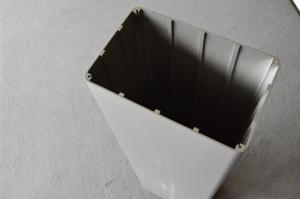

Aluminium Profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the safety features of aluminum profiles in construction?

- Aluminum profiles in construction offer a range of safety features that make them a popular choice for various applications. First and foremost, aluminum profiles are lightweight yet durable, making them easy to handle and install while still providing structural integrity. This reduces the risk of accidents or injuries during the construction process. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the spread of fire. This is a crucial safety feature in construction, as it helps to minimize the potential for fire-related hazards and ensures the safety of occupants. Aluminum profiles also have excellent corrosion resistance properties. They are naturally resistant to rust and decay, which means they can withstand harsh environmental conditions and maintain their structural integrity over time. This is particularly important in coastal or humid areas where the risk of corrosion is higher. Furthermore, aluminum profiles can be designed to incorporate safety features such as non-slip surfaces or grooves for enhanced grip and stability. This is especially beneficial in applications where slip and fall accidents may occur, such as staircases or walkways. Aluminum profiles also offer excellent electrical conductivity, which can be advantageous when considering safety in electrical installations. Their high thermal conductivity helps dissipate heat efficiently, reducing the risk of overheating or electrical malfunctions. Lastly, aluminum profiles are recyclable, which aligns with sustainable construction practices. By using aluminum profiles, construction projects can contribute to reducing waste and environmental impact. Overall, the safety features of aluminum profiles in construction include their lightweight yet durable nature, non-combustibility, corrosion resistance, ability to incorporate non-slip surfaces, excellent electrical conductivity, and recyclability. These features combine to create a safe and sustainable construction material choice.

- Q: What is the material content of 4040 aluminum alloy profiles?

- Aluminium alloy grade: 6063Silicon (Si) 0.2-0.6%,Iron (Fe) 0.35%,Copper (Cu) 0.1%,Manganese (Mn) 0.1%,Magnesium (Mg) 0.45-0.9%,Chromium (Cr) 0.1%,Zinc (Zn) 0.1%,Titanium (Ti) 0.1%Other metals accounted for 0.15% of the total,Aluminum (Al) 97.35--98.35%Shanghai Australia Hong Industrial Aluminum Co., Ltd. specializes in providing1. mold development and design2. extrusion of industrial aluminum extrusions3. industrial aluminum parts4. industrial aluminum profiles and assembly lines, tables, transmission line equipment development and installation

- Q: This question asks about the various dimensions and forms of aluminum profiles that are typically utilized in the construction of building frames.

- <p>Aluminum profiles used in building frames come in a variety of sizes and shapes to meet different structural requirements. Common profiles include rectangular tubes, square tubes, angles (L-profiles), channels, and tees. Sizes range from small (e.g., 10x10mm to 30x30mm) to large (e.g., 100x100mm to 200x200mm), with thicknesses varying from 1mm to 6mm or more. Shapes are tailored to specific applications; for example, I-beams and H-beams are used for their high strength-to-weight ratio. These profiles are chosen based on load-bearing needs, aesthetic preferences, and construction techniques.</p>

- Q: Are aluminum profiles suitable for constructing interior partitions or ceilings in commercial buildings?

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings in commercial buildings. They offer several advantages such as strength, durability, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be custom designed to fit specific architectural requirements. They also provide good thermal insulation and can be used in both new constructions and renovations.</p>

- Q: This question asks about the various types of insulation panels that utilize aluminum profiles in their construction.

- <p>Insulation panels made from aluminum profiles come in several types, each with specific characteristics and applications. These include: 1. Sandwich Panels, which consist of two aluminum sheets with a core material like polyurethane, rockwool, or polystyrene. 2. Composite Panels, which combine aluminum with other materials for enhanced properties. 3. Structural Insulated Panels (SIPs), used in construction for their thermal efficiency and strength. 4. Cold Storage Panels, designed to maintain low temperatures in refrigeration units. 5. Acoustic Insulation Panels, which reduce noise transfer. Each type is chosen based on the required thermal, acoustic, and structural performance.</p>

- Q: Are aluminum profiles suitable for use in automotive suspension systems?

- Indeed, automotive suspension systems can benefit from the use of aluminum profiles. Aluminum, being both lightweight and strong, offers numerous advantages in suspension design. To begin with, the lightweight properties of aluminum profiles contribute to reducing the overall weight of the suspension system. This not only improves fuel efficiency but also enhances the vehicle's performance and handling. The decreased weight allows for faster acceleration, improved braking, and enhanced maneuverability. Moreover, aluminum profiles possess an exceptional strength-to-weight ratio, enabling them to withstand high loads and stresses while remaining lightweight. This makes them ideal for handling the dynamic loads experienced by suspension systems, such as bumps, vibrations, and impacts. Aluminum profiles can effectively absorb and distribute these loads, ensuring a smooth and comfortable ride for the vehicle occupants. Additionally, aluminum is highly resistant to corrosion, which is of utmost importance in automotive applications. Given that suspension systems are exposed to various environmental conditions, including moisture, salt, and road debris, the use of aluminum profiles minimizes the risk of corrosion. This, in turn, enhances the durability and longevity of the suspension components. Furthermore, aluminum profiles offer great versatility and can be easily shaped and formed into complex geometries required for suspension system components. This allows for greater design flexibility and optimization of performance. Aluminum profiles can be utilized in the manufacturing of various suspension components, including control arms, knuckles, and subframes. In conclusion, aluminum profiles are unquestionably suitable for use in automotive suspension systems. Their lightweight nature, high strength-to-weight ratio, corrosion resistance, and design flexibility make them an excellent choice for maximizing the performance, efficiency, and durability of suspension systems in vehicles.

- Q: Are aluminum profiles suitable for the furniture industry?

- Aluminum profiles prove to be an excellent choice for the furniture industry due to their many advantages. The versatility and durability of aluminum make it a highly sought-after material for furniture manufacturing. To begin with, the lightweight nature of aluminum profiles simplifies handling and transportation, particularly for larger furniture pieces. Not only does this decrease transportation expenses, but it also enhances the user-friendliness of the furniture during installation and rearrangement. Furthermore, aluminum's remarkable resistance to corrosion ensures that furniture made with aluminum profiles can endure harsh weather conditions and maintain its durability over time. This quality makes it suitable for both indoor and outdoor furniture applications. In addition, aluminum profiles offer exceptional design flexibility. The ease with which aluminum can be extruded into various shapes and sizes allows for limitless design possibilities. This versatility facilitates the creation of customized furniture pieces that cater to specific client requirements. Moreover, the strength-to-weight ratio of aluminum profiles is commendable. Furniture constructed with aluminum becomes robust and long-lasting, which is particularly advantageous for items that experience regular use, such as chairs and tables. Additionally, aluminum is an environmentally-friendly material, as it is fully recyclable. This aligns with the increasing demand for sustainable furniture options. Manufacturers can effortlessly recycle aluminum profiles at the end of their lifecycle and employ the recycled material to fashion new furniture items, thereby reducing waste and contributing to a circular economy. In conclusion, the unique attributes of aluminum profiles make them highly fitting for the furniture industry. Their lightweight composition, resistance to corrosion, design flexibility, strength, and recyclability collectively contribute to the creation of superior-quality and sustainable furniture products.

- Q: What are the advantages of using aluminum profiles in the oil and gas industry?

- There are several advantages of using aluminum profiles in the oil and gas industry. Firstly, aluminum profiles are lightweight yet highly durable, making them ideal for applications that require strength and resistance to harsh environments. Secondly, aluminum profiles have excellent corrosion resistance properties, ensuring their longevity even in corrosive environments found in the oil and gas industry. Additionally, aluminum profiles offer excellent thermal conductivity, allowing for efficient heat transfer and management in various oil and gas processes. Furthermore, aluminum profiles are easy to fabricate and assemble, enabling quick and cost-effective installation. Lastly, aluminum is a recyclable material, aligning with sustainability goals and reducing environmental impact in the oil and gas industry.

- Q: Are aluminum profiles suitable for use in flooring systems?

- <p>Yes, aluminum profiles can be used for flooring systems. They are known for their strength, durability, and resistance to corrosion, making them ideal for various flooring applications. Aluminum profiles can be used to create modular flooring systems, providing a lightweight and easy-to-install solution. They can also be used in conjunction with other materials to create hybrid flooring systems, offering a combination of benefits such as thermal insulation, acoustic performance, and structural integrity.</p>

- Q: What are the environmental effects of utilizing aluminum profiles in the construction industry?

- <p>Yes, there are environmental impacts associated with using aluminum profiles in construction. Aluminum production is energy-intensive, which contributes to greenhouse gas emissions. However, aluminum is recyclable, and its recycling process requires significantly less energy than primary production, reducing environmental impact. Additionally, aluminum profiles are lightweight, which can reduce transportation emissions. Despite these benefits, concerns remain about the energy used in aluminum production and the potential for leaching of aluminum into the environment, which can affect soil and water quality.</p>

Send your message to us

Aluminum Extrusion Channel Profiles - Aluminum Profile 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords