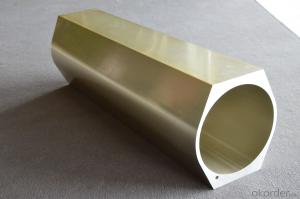

Aluminum Extrusion U Channel Profiles - Industrial Aluminum Profile Hot Selling DW-002

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industial Aluminum Profile

Alloy: 6063, Temper: T5, T6.

surface:mill finished,anodized3.

widely used for building,furniture,transportation

Industial Aluminum Profile

Alloy: 6063,

Temper: T5, T6.

building,furniture,transportation,machine

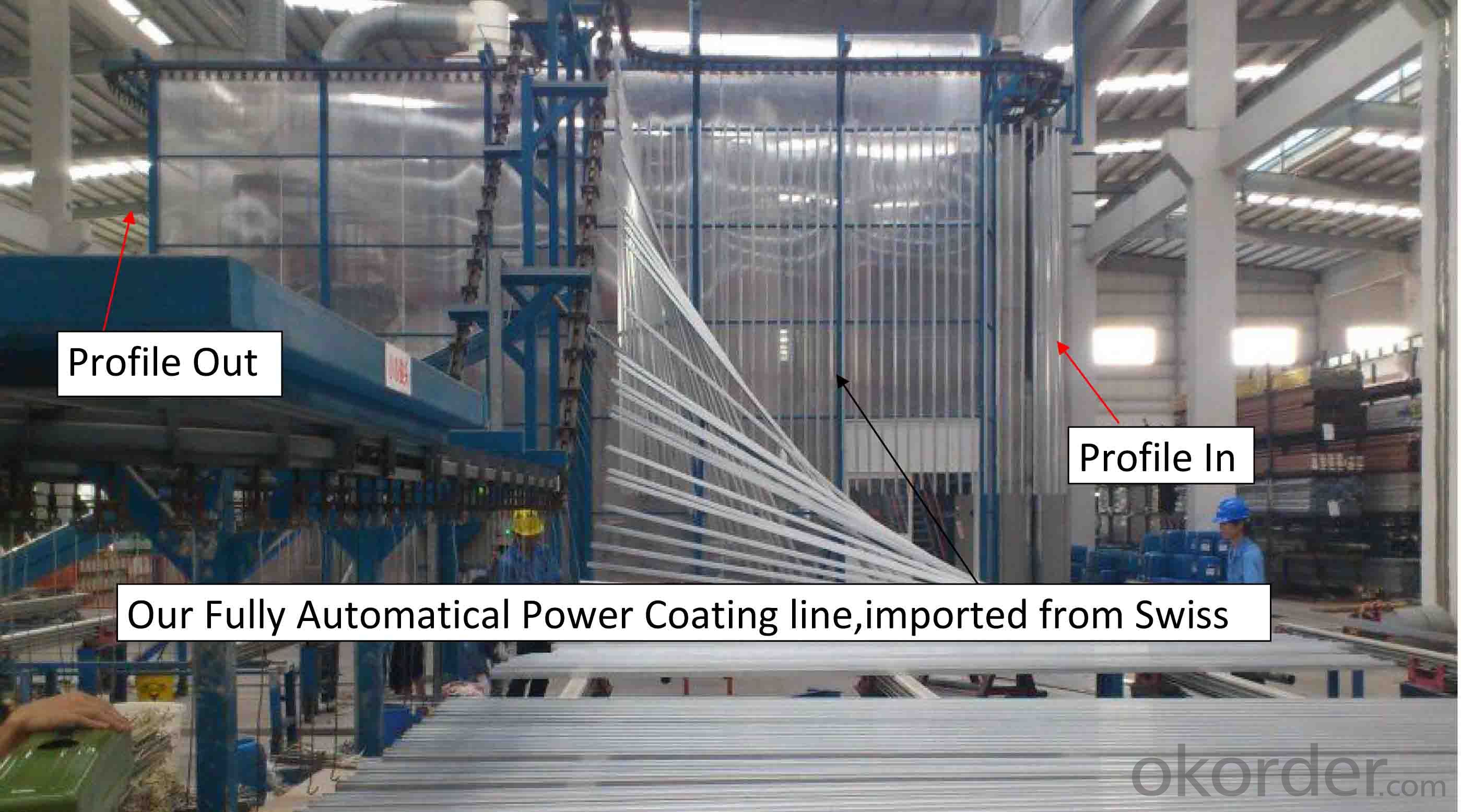

Anodized silver, anodized champagne, anodized bronze, anodized black, powder coated, electrophoresis, polished, Thermal break, wooden grain.

Length: 5.8---6 meters, depend on customers' requested.

Packing: kraft paper, carton, or on customers' requested.

Exported to different countries worldwide.

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: Tips for identifying aluminum profiles

- For the mechanical framework of aluminum on the market quality is not good, consumers can use a simple method to distinguish aluminum, so you use the time better.

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: What is the thickness of the aluminum alloy window frame?

- According to the provisions of GB5237.1-2008, aluminum profile wall thickness not less than 1.2mm. The size of the wall must be calculated after the pressure bearing is calculated.

- Q: What are the different shapes and sizes of aluminum profiles available?

- Aluminum profiles come in various shapes and sizes depending on their application. Some common shapes include T-shape, U-shape, square, round, and rectangular. The sizes can range from small profiles used for decorative purposes to larger ones used in structural applications. The dimensions of these profiles can vary, with width, height, and thickness being the key factors. Additionally, custom profiles can also be manufactured to meet specific requirements.

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: What are the environmental effects of utilizing aluminum profiles in the construction industry?

- <p>Yes, there are environmental impacts associated with using aluminum profiles in construction. Aluminum production is energy-intensive, which contributes to greenhouse gas emissions. However, aluminum is recyclable, and its recycling process requires significantly less energy than primary production, reducing environmental impact. Additionally, aluminum profiles are lightweight, which can reduce transportation emissions. Despite these benefits, concerns remain about the energy used in aluminum production and the potential for leaching of aluminum into the environment, which can affect soil and water quality.</p>

- Q: Do aluminum profiles require any special tools or equipment for installation?

- Yes, aluminum profiles typically require specific tools and equipment for installation. These may include a miter saw or aluminum cutting saw, drill press or power drill, measuring tools, screwdrivers, clamps, and fasteners specific to aluminum profiles. Additionally, certain installations may require specialized equipment such as a router or end milling machine for precision cuts and shaping.

- Q: Can recycled aluminum be utilized in construction projects as an alternative to new, raw materials?

- <p>Yes, recycled aluminum can be used in building projects as an alternative to new raw materials. It is not only cost-effective but also environmentally friendly, reducing the energy required for production and the amount of waste sent to landfills. Recycled aluminum maintains the same strength and durability as new aluminum, making it suitable for various construction applications. However, it's important to ensure that the recycled aluminum meets the necessary quality standards and specifications for your project to avoid any structural or safety issues.</p>

Send your message to us

Aluminum Extrusion U Channel Profiles - Industrial Aluminum Profile Hot Selling DW-002

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 0.5 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords