Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

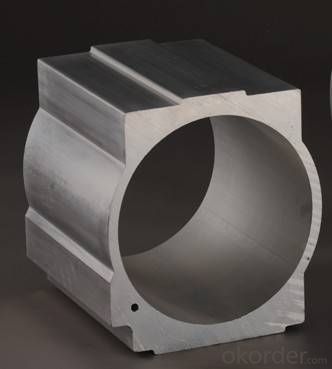

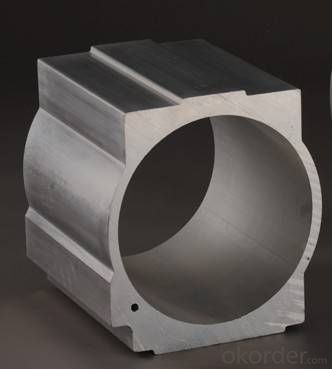

1. Structure of Aluminium Extrusion Profiles For Motor Cylinder Shell Description

Aluminium Extrusion Profiles For Motor Cylinder Shell is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Extrusion Profiles For Motor Cylinder Shell

Aluminium Extrusion Profiles For Motor Cylinder Shell | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Extrusion Profiles For Motor Cylinder Shell

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Extrusion Profiles For Motor Cylinder Shell

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Extrusion Profiles For Motor Cylinder Shell

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Aluminium Extrusion Profiles For Motor Cylinder Shell

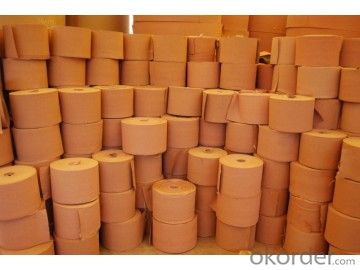

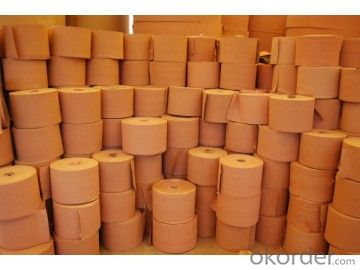

7. Package and shipping of Aluminium Extrusion Profiles For Motor Cylinder Shell

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: What is the thickness of the aluminum alloy window frame?

- According to the GB / T5237 Aluminum Alloy "building materials" regulations, construction aluminum minimum nominal wall thickness should be not less than 1.2mm, wherein the solid profile wall thickness error of 0.15mm, namely the wall thickness not less than 1.05mm; hollow profile parts containing a closed cavity wall thickness allowance of 0.23mm, the wall thickness is not lower than 0.97mm.

- Q: What are the different alloys available for aluminum profiles?

- Aluminum profiles have numerous alloy options, each with its own distinct properties and characteristics. Some widely used alloys include: 1. 6061-T6: This alloy is extensively utilized for aluminum profiles due to its exceptional strength, resistance to corrosion, and weldability. It finds application in structural components like frames, beams, and supports. 2. 6063-T5: Known for its excellent formability and ability to be extruded, this alloy is perfect for creating intricate shapes and designs. It possesses good corrosion resistance and is commonly employed in architectural projects such as window frames and curtain walls. 3. 7075-T6: This alloy offers remarkable strength and toughness, making it suitable for demanding applications such as aerospace components and high-stress structural parts. 4. 6082-T6: Similar to 6061-T6 in terms of strength and corrosion resistance, this alloy offers enhanced machinability. It is frequently utilized in the automotive and transportation industries. 5. 3003-H14: This alloy is primarily chosen for its excellent resistance to corrosion. It finds application in marine settings, as well as in chemical and food processing industries. These examples represent only a fraction of the available aluminum profile alloys. The selection of the appropriate alloy depends on specific requirements, such as desired strength, corrosion resistance, formability, and machinability, for a given application.

- Q: How are aluminum profiles cut and shaped?

- Depending on the desired result, there are various methods available for cutting and shaping aluminum profiles. One popular approach involves the use of saws. Whether it's a hand saw or a power saw like a miter saw or circular saw, specially designed blades capable of cutting through aluminum are utilized. Alternatively, CNC (Computer Numerical Control) machines provide a highly precise option. By programming these machines, aluminum profiles can be cut and shaped with great accuracy. This technique is particularly suitable for intricate and complex designs. Shaping aluminum profiles can be achieved through different techniques as well. For instance, bending is a common method. Specialized bending machines apply force gradually to achieve the desired angle without causing any damage or deformation to the aluminum. Another shaping technique is extrusion. This involves forcing the aluminum through a die to create a specific shape. Extrusion is commonly employed in the manufacturing of aluminum profiles with consistent cross-sectional shapes like tubes or beams. Overall, achieving the desired results in cutting and shaping aluminum profiles necessitates the use of specialized tools and machinery. The specific method chosen depends on the complexity of the design and the desired outcome.

- Q: What are the different shapes and profiles available for aluminum profiles?

- Aluminum profiles come in various shapes and profiles, each with its own distinct characteristics and uses. Let's explore some of the most common options: 1. Square and rectangular profiles: These profiles have straight sides and sharp corners, making them perfect for applications that require strength and rigidity. They are frequently utilized in architectural structures, frames, and support systems. 2. T-shape profiles: T-shaped profiles consist of a perpendicular flange or arm extending from a larger base. They are often employed for structural purposes, providing additional strength and support in beams and columns. 3. Round profiles: Round profiles have a circular cross-section and are frequently preferred in applications that demand a smooth and seamless appearance. They are commonly found in decorative uses like handrails, lighting fixtures, and furniture. 4. Angle profiles: Angle profiles have two sides perpendicular to each other, creating a 90-degree angle. These profiles are commonly used in corner protection, edging, and framing applications. They are frequently seen in industries such as construction, manufacturing, and automotive. 5. I-beam profiles: I-beam profiles feature a central vertical web with flanges on either side, forming an "I" shape. These profiles are renowned for their high strength-to-weight ratio and are commonly used in structural applications like bridges, buildings, and heavy-duty machinery. 6. Custom profiles: In addition to the standard shapes mentioned above, aluminum profiles can also be custom-designed and extruded to meet specific requirements. This allows for endless possibilities in terms of shape, size, and functionality. In conclusion, the wide range of aluminum profile shapes and profiles enables versatility and adaptability in various industries and applications. Whether you prioritize strength, aesthetics, or a combination of both, there is an aluminum profile shape and profile that will suit your specific needs.

- Q: Is aluminum factory harmful to people?

- But most companies now have the ability to avoid these dangers. Only those illegal backward production capacity will do some damage to the environment for money. These national policies, the city firmly banned the shutting down.

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: Are aluminum profiles suitable for railway and transportation systems?

- Railway and transportation systems can greatly benefit from the use of aluminum profiles. Aluminum, being both lightweight and strong, is an ideal material for applications that demand a high strength-to-weight ratio, such as the construction of railway and transportation systems. One of the main advantages of utilizing aluminum profiles in these systems is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which effectively prevents rusting and corrosion, even in harsh environmental conditions. Consequently, this ensures the longevity and durability of the railway and transportation systems, thereby reducing maintenance requirements and costs. Furthermore, aluminum profiles offer great design flexibility. They can be effortlessly fabricated into various shapes and sizes, allowing for customization to meet the specific requirements of railway and transportation systems. This versatility allows for the creation of lightweight yet sturdy structures that can withstand the dynamic loads and vibrations experienced in transportation applications. Another advantage of aluminum profiles is their recyclability. Aluminum is one of the most recyclable materials, boasting a high recycling rate. This makes it an eco-friendly choice for railway and transportation systems, aligning with sustainable practices. Moreover, aluminum profiles possess excellent electrical conductivity and thermal properties. This makes them suitable for applications that necessitate efficient heat dissipation, electromagnetic shielding, or electrical connections in railway and transportation systems. To summarize, due to their lightweight nature, strength, corrosion resistance, design flexibility, recyclability, and electrical and thermal properties, aluminum profiles are highly suitable for railway and transportation systems. These characteristics make aluminum an ideal material for constructing transportation infrastructure that is both durable and efficient, while also being environmentally friendly.

- Q: This question asks for a list of different types of fasteners that are typically used in conjunction with aluminum extrusions.

- <p>Common types of fasteners used with aluminum extrusions include: 1. T-nuts and T-bolts, which provide a secure way to mount components to the extrusion. 2. Clamps and brackets, which can be used to hold items in place without drilling. 3. Corner brackets, which are used to connect two extrusions at right angles. 4. End caps, which protect the ends of the extrusion and can also serve as a mounting point. 5. Dowel pins, which are used to align and secure extrusions together. 6. Spacers, which maintain a consistent distance between extrusions. 7. Adhesives, which can be used for bonding parts to the extrusion. 8. Rivets, which provide a permanent connection between extrusions and other materials. These fasteners are chosen based on the specific application, load requirements, and design considerations.</p>

- Q: What are the specific needs or standards for utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, aluminum profiles must meet certain requirements to ensure durability and functionality. These include resistance to extreme temperatures, which may affect the material's strength and flexibility. Profiles should be made from high-quality aluminum alloys designed for low-temperature performance. Additionally, proper thermal breaks may be necessary to prevent heat loss through the profile. Corrosion resistance is also crucial, as cold environments can accelerate the process. Lastly, it's essential to consider the expansion and contraction of aluminum in cold temperatures, ensuring the design accommodates these changes to prevent warping or cracking.</p>

Send your message to us

Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords