Aluminum Profiles Dubai for Kitchen Cabinet Frame Door Frames

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Profiles for Kitchen Cabinet Frame Door Frames

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profiles for Kitchen Cabinet Frame Door Frames

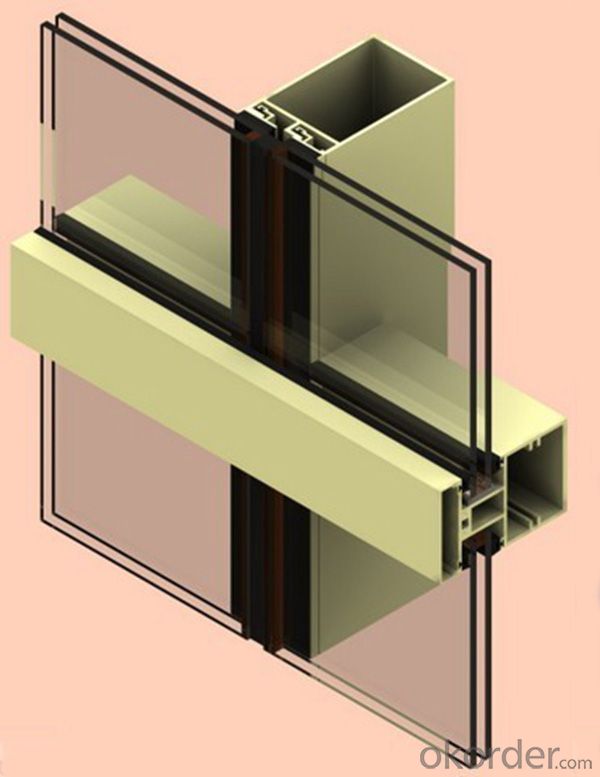

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profiles for Kitchen Cabinet Frame Door Frames

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

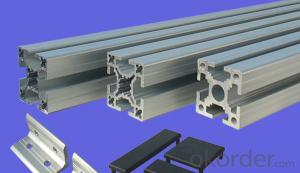

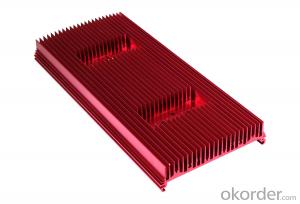

5. Image of Aluminum Profiles for Kitchen Cabinet Frame Door Frames

6. Package and shipping of Aluminum Profiles for Kitchen Cabinet Frame Door Frames

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Hardness is generally measured by a Brinell hardness tester. T5 is subjected to high temperature molding and air cooling quenching in the shortest possible time. The T6 is treated with solid solution after artificial aging. So there is a difference between the two. But from the appearance of it is difficult to judge, experienced hands can be used to swing aluminum, roughly judged

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum profiles used in window and door frames.

- <p>Aluminum profiles used for windows and doors can have several finishes to enhance their appearance and durability. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; thermal spraying, which applies a coating to improve resistance to wear; and electrophoretic coating, which provides a smooth, even finish. Additionally, there are finishes like polishing for a shiny look, brushing for a matte appearance, and wood grain transfer for a natural aesthetic. Each finish serves a specific purpose, from enhancing visual appeal to providing corrosion resistance and UV protection.</p>

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. Aluminum is a versatile and lightweight material that offers various benefits for exhibition booth construction. Firstly, aluminum profiles are easy to work with and can be easily cut, drilled, and assembled to create custom booth designs. This flexibility allows for creativity and customization to meet specific booth requirements. Additionally, aluminum profiles are highly durable and long-lasting. They are resistant to corrosion, rust, and other environmental factors, which ensures that the exhibition booth can withstand the rigors of multiple events and maintain its appearance over time. This durability also makes aluminum profiles a cost-effective choice, as they require minimal maintenance and can be reused for future exhibitions. Furthermore, aluminum profiles offer a sleek and professional aesthetic that can enhance the overall presentation of the exhibition booth. The material can be finished with various coatings, such as paint or anodizing, to achieve the desired look and branding. Moreover, aluminum profiles can be easily integrated with other materials, such as glass, acrylic, or fabric, to create visually appealing displays within the booth. Lastly, aluminum profiles provide structural stability while remaining lightweight. This is crucial for exhibitors who need to transport and assemble their booths frequently. The lightweight nature of aluminum profiles makes them easy to handle, reducing logistical challenges and costs associated with booth setup and dismantling. Overall, aluminum profiles offer numerous advantages that make them suitable for exhibition booths. Their versatility, durability, aesthetic appeal, and ease of use make them an excellent choice for exhibitors looking to create eye-catching and functional booth designs.

- Q: What are the different surface treatment options available for aluminum profiles?

- There are several surface treatment options available for aluminum profiles, each offering unique benefits and enhancing their appearance and performance. Some of the common surface treatments for aluminum profiles include: 1. Anodizing: Anodizing is a popular surface treatment method that creates a protective oxide layer on the aluminum surface. It offers excellent corrosion resistance, durability, and can be made in various colors. Anodized aluminum profiles are commonly used in architectural, automotive, and aerospace applications. 2. Powder coating: Powder coating involves applying a dry powder to the aluminum surface and then curing it with heat. This process creates a tough, decorative, and protective layer that enhances the profile's durability, scratch resistance, and weatherability. Powder-coated aluminum profiles are widely used in the construction industry due to their aesthetic appeal and resistance to fading. 3. Electrophoretic coating: Also known as electrocoating or e-coating, this process involves immersing the aluminum profile in a bath of paint and applying an electric current to deposit the paint particles uniformly. Electrophoretic coating provides excellent corrosion resistance, uniform thickness, and a smooth finish. It is commonly used in the automotive and electronics industries. 4. Mechanical finishing: Mechanical finishing techniques, such as brushing or polishing, are used to enhance the appearance and smoothness of aluminum profiles. Brushing creates a brushed or satin finish, while polishing creates a mirror-like, reflective surface. These finishes are often applied to decorative or architectural aluminum profiles. 5. Chemical etching: Chemical etching involves selectively removing material from the aluminum surface using an acid or chemical solution. This process can create decorative patterns, logos, or text on the profile's surface. Chemical etching is commonly used for branding or aesthetic purposes in various industries. 6. Plating: Plating is the process of depositing a thin layer of metal, such as chrome or nickel, onto the aluminum surface. This treatment enhances the appearance, corrosion resistance, and wear resistance of aluminum profiles. Plated aluminum profiles are often used in the automotive, electronics, and decorative industries. It's important to note that the choice of surface treatment depends on the specific requirements of the application, such as aesthetics, durability, corrosion resistance, or conductivity. Consulting with a professional or supplier can help determine the most suitable surface treatment option for aluminum profiles based on your needs.

- Q: This question asks for a list of various fasteners that can be used to connect aluminum profiles to building structures.

- <p>There are several types of fasteners used to attach aluminum profiles to building structures, including: 1. Bolts and Nuts: Commonly used for strong and secure connections. 2. Rivets: Provide a permanent connection by deforming the rivet when installed. 3. Self-tapping Screws: Can be used to create a thread in the aluminum profile without pre-tapping. 4. Adhesives: Used for bonding profiles together, often in conjunction with mechanical fasteners. 5. Welding: Although not a fastener, welding can join aluminum profiles together by melting and fusing the materials. 6. Clamps and Brackets: Used to hold profiles in place temporarily or permanently. 7. Dowels and Pins: Used for alignment and positioning of profiles. Each type of fastener has its specific applications and advantages depending on the structural requirements and design considerations.</p>

- Q: Can aluminum profiles be customized according to specific requirements?

- Yes, aluminum profiles can be customized according to specific requirements.

- Q: Can aluminum profiles be used in telecommunications infrastructure?

- Yes, aluminum profiles can be used in telecommunications infrastructure. Aluminum is a lightweight and versatile material that offers several advantages in telecommunications applications. It is corrosion-resistant, which makes it suitable for outdoor installations where it may be exposed to harsh weather conditions. Aluminum profiles are also easy to fabricate and can be customized to meet specific requirements, such as mounting brackets, cable trays, or equipment racks. In addition, aluminum profiles have excellent electrical conductivity, which is crucial in telecommunications infrastructure to ensure efficient signal transmission. They can be used for various purposes, including the construction of transmission towers, antenna supports, and base stations. Furthermore, aluminum is a sustainable material as it can be recycled repeatedly without losing its properties. This aligns with the growing focus on environmental sustainability in the telecommunications industry. Overall, aluminum profiles offer a cost-effective and reliable solution for telecommunications infrastructure, providing durability, flexibility, and excellent electrical conductivity.

- Q: This question asks about the various methods used to finish aluminum profiles, including painting and coating.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance, durability, and functionality. Common methods include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, an electrostatic process that offers a durable and colorful finish. 3. Painting, which can be done with various types of paint for aesthetic or protective purposes. 4. Polishing, which gives a shiny, smooth surface finish. 5. Brushing, creating a textured, satin-like appearance. 6. Electroplating, which deposits a thin layer of metal onto the aluminum for decorative or protective reasons. Each method has its advantages and is chosen based on the specific requirements of the application.</p>

- Q: Are aluminum profiles suitable for balcony railings?

- Indeed, balcony railings can be effectively made using aluminum profiles. Aluminum is a favored material for balcony railings because it possesses qualities such as resilience, robustness, and minimal upkeep requirements. Its resistance to rust and corrosion makes it exceedingly appropriate for outdoor applications. Moreover, aluminum profiles can be effortlessly tailored and molded to match any desired design or architectural style. Although lightweight, they offer ample strength to ensure necessary support and safety for balcony railings. Additionally, aluminum railings are obtainable in a plethora of finishes and colors, providing limitless possibilities for design. On the whole, aluminum profiles are a dependable and fashionable choice for balcony railings.

Send your message to us

Aluminum Profiles Dubai for Kitchen Cabinet Frame Door Frames

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords