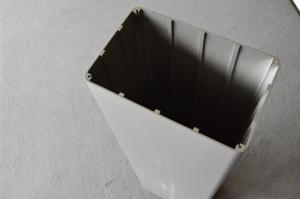

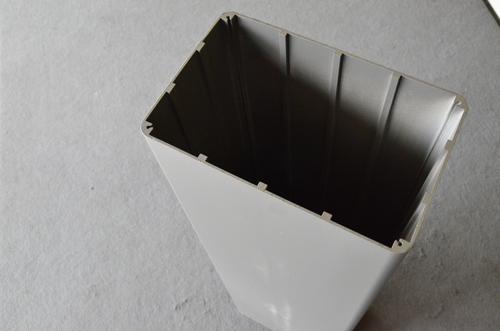

Aluminum Extrusion Tube Profiles - Aluminum Sections 04

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

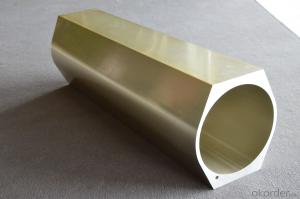

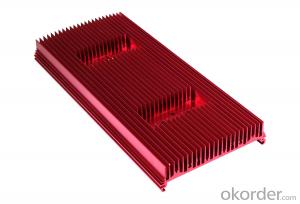

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks for guidance on selecting the appropriate aluminum profiles for a construction project.

- <p>Choosing the right aluminum profiles for your building project involves several steps. First, consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental conditions. Consult with engineers or architects to determine the appropriate strength, size, and shape of the profiles. Next, evaluate the quality of the aluminum, ensuring it meets industry standards for durability and resistance to corrosion. Look for profiles with good thermal insulation properties and UV resistance to maintain performance over time. Finally, consider the cost-effectiveness and availability of the profiles, as well as the ease of installation and maintenance. Always opt for reputable suppliers to ensure you receive high-quality products that meet your project's needs.</p>

- Q: Can aluminum profiles be used in lightweight construction applications?

- Aluminum profiles are definitely applicable in lightweight construction. They possess a lightweight and versatile nature that brings numerous advantages to construction projects. With a high strength-to-weight ratio, structures can be built with less material yet still maintain strength and durability. This makes aluminum profiles an ideal choice for lightweight construction where weight reduction is crucial. Various construction projects, including building facades, interior partitions, roofing systems, and structural frameworks, commonly utilize aluminum profiles. They are particularly favored in industries such as aerospace, automotive, and marine where reducing weight is of utmost importance. Additionally, aluminum profiles exhibit excellent resistance to corrosion, making them suitable for outdoor and high-moisture environments. Their high malleability allows for easy fabrication into different shapes and sizes, enabling customized designs and simple installation. Moreover, aluminum is an eco-friendly material as it can be recycled infinitely without compromising its properties. To sum up, the widespread use of aluminum profiles in lightweight construction stems from their lightweight nature, strength, durability, corrosion resistance, malleability, and environmental benefits.

- Q: High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum Alloy profiles are GB and non-standard, the state has special provisions on the thickness of the material, material requirements, each with the aluminum bar is not the same, we know that there are 6063-T5, A and aluminum and the B rods and even more, it shows a aluminum problem, raw materials and good poor relationship with out the quality of the materials, profiles of many kinds of Oh, high compartment aluminum, 80, paragraph 84 of paragraph 100, many Oh, don't be fooled that each kind of aluminum are the same, with the recovery of aluminum ingots is not the same as that of pure

- Q: Are aluminum profiles suitable for high-temperature environments?

- Aluminum profiles are generally not suitable for high-temperature environments. While aluminum has excellent thermal conductivity and is a lightweight material, it has a relatively low melting point compared to other metals. Aluminum begins to soften at temperatures above 400°C (752°F) and can lose its structural integrity at higher temperatures. In high-temperature environments, aluminum profiles may experience deformation, distortion, or even complete failure. This can compromise the stability and functionality of any structure or system relying on aluminum profiles. However, there are certain types of aluminum alloys that are specifically designed to withstand higher temperatures. These alloys, such as 6061 and 7075, have improved heat resistance and can tolerate higher temperatures without significant damage. These specialized alloys are commonly used in applications requiring higher temperature resistance, such as aerospace components or certain industrial processes. Nevertheless, it is crucial to carefully consider the specific temperature requirements of a given environment before using aluminum profiles. In extreme high-temperature environments, other materials like steel or refractory metals may be more suitable due to their higher melting points and superior heat resistance properties.

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Yes, aluminum profiles are suitable for use in the renewable energy industry. Aluminum is lightweight, durable, and corrosion-resistant, making it ideal for applications such as solar panel frames, wind turbine components, and electrical infrastructure. It also offers excellent thermal conductivity and recyclability, aligning with the sustainability goals of the renewable energy sector.

- Q: Is it possible to utilize recycled aluminum from various sources to manufacture new aluminum profiles?

- <p>Yes, recycled aluminum can be used to create new aluminum profiles. The process involves melting down the recycled aluminum, which can then be reformed into new shapes and profiles. This not only conserves resources but also reduces energy consumption compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a wide range of applications, from construction to automotive industries.</p>

- Q: Can aluminum profiles be used in HVAC systems?

- Yes, aluminum profiles can be used in HVAC systems. They are commonly used for constructing ductwork, heat exchangers, and other components due to their lightweight, corrosion-resistant, and durable properties. Aluminum profiles are also easily customizable, making them suitable for various HVAC applications.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors used with aluminum profiles, including corner brackets, corner blocks, T-slot corner connectors, and corner gussets. These connectors help to create strong and stable joints between aluminum profiles, allowing for the construction of various structures and frameworks.

- Q: Are aluminum profiles suitable for balcony railings?

- Yes, aluminum profiles are suitable for balcony railings. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an excellent choice for outdoor applications like balcony railings. Additionally, aluminum profiles can be easily customized and come in a variety of designs, making them versatile and aesthetically pleasing options for balcony railings.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum profiles offer lightweight, durable, and corrosion-resistant properties, making them suitable for various interior components such as door panels, dashboard trims, seat frames, and console accents. Additionally, aluminum profiles can be easily customized and integrated with other materials, allowing for innovative designs and improved functionality in automotive interiors.

Send your message to us

Aluminum Extrusion Tube Profiles - Aluminum Sections 04

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords