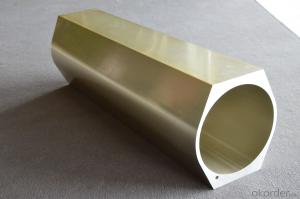

Custom Cina Extruded Aluminum Profiles - Aluminum Profile 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Pharmaceutical manufacturing can benefit greatly from the use of aluminum profiles. These profiles offer a range of advantages in the industry due to the versatile and lightweight nature of aluminum. One crucial advantage is the corrosion resistance of aluminum profiles, which is of utmost importance in pharmaceutical manufacturing where cleanliness and hygiene are vital. Aluminum does not rust or deteriorate when exposed to moisture, making it an ideal material for cleanrooms and sterile environments. Furthermore, aluminum profiles are easy to clean and maintain, maintaining their structural integrity even after rigorous cleaning processes such as sterilization and disinfection. This ensures that the pharmaceutical manufacturing equipment remains in a pristine and contamination-free condition. Customization is another key benefit of aluminum profiles in pharmaceutical manufacturing. These profiles can be easily fabricated into various shapes and sizes, allowing for the creation of complex structures and machinery. This flexibility makes aluminum profiles an excellent choice for designing precise pharmaceutical equipment, including conveyor systems, processing machinery, and packaging equipment. Additionally, aluminum profiles possess excellent thermal conductivity, which is advantageous in pharmaceutical manufacturing processes that involve temperature control. Freeze-drying, sterilization, and granulation, for example, can benefit from efficient heat transfer provided by aluminum profiles. This ensures that pharmaceutical products are processed and stored at the desired temperature. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, reducing the carbon footprint associated with pharmaceutical manufacturing. The ability to reuse and repurpose aluminum profiles contributes to a circular economy and minimizes waste generation. In conclusion, aluminum profiles are highly suitable for pharmaceutical manufacturing. Their corrosion resistance, ease of cleaning, customization options, thermal conductivity, and sustainability make them an excellent choice for designing and fabricating pharmaceutical equipment and machinery.

- Q: What are the different machining techniques used on aluminum profiles?

- Some of the different machining techniques used on aluminum profiles include milling, drilling, turning, grinding, and tapping. These processes help shape and refine the aluminum profiles to meet specific design requirements and achieve desired dimensions and surface finishes.

- Q: Surface treatment method of aluminium profile

- Five most common surface treatment methods for aluminum profilesFabric: Aluminum matte matte surface aluminum profile Aluminum Alloy to avoid the presence of light interference will form light environment, under the condition of building decoration in the shortcomings of its surface such as brocade as soft and delicate, very popular with the favor of the market, but the existing grinding material must overcome the uneven surface of the sand, and can see the lack of pattern.Multi color surface treatment of aluminum: the monotonous white and tinted silver has been unable to meet the good cooperation of architects and the exterior decorative tile, exterior wall latex, new stainless steel color, champagne, gold, gold, titanium series (red wine, red jujube red, black, purple etc.) plus color glass the decorative effect of the icing on the cake. These shapes must be chemically or mechanically polished and then oxidized to better effect.Electrocoating aluminium profiles: electrophoretic coating profiles of surface soft luster, can resist the erosion of acid rain, cement mortar, Japan 90% aluminum after electrophoretic coating.Powder electrostatic spraying aluminum profile: powder electrostatic spraying profile is characterized by excellent corrosion resistance, acid, alkali, salt fog is much better than oxidation coloring section.Plasma enhanced electrochemical surface ceramic aluminum profile: this type of material is the most advanced processing technology in the world today. The profile products are of good quality, but the cost is higher. It has more than 20 kinds of colors, the biggest feature is that it can be printed as needed according to the printing cloth, the surface of the section is colourful and the decoration effect is excellent.

- Q: This question asks for a comparison between aluminum profiles and other materials commonly used for roofing, focusing on their characteristics and performance.

- <p>Aluminum profiles for roofing are known for their durability, corrosion resistance, and lightweight nature. Compared to materials like steel, they are less prone to rust and offer a longer lifespan with minimal maintenance. When compared to traditional materials like wood or clay tiles, aluminum profiles are more resistant to weathering and do not rot or warp. They also have a high strength-to-weight ratio, making them ideal for structures that require lighter roofing materials. Additionally, aluminum profiles can be easily recycled, contributing to sustainability efforts. However, they may not offer the same aesthetic appeal as traditional materials and can be more expensive upfront.</p>

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Subject to circumstances:1, aluminum material or brand2 、 what is the forming state of aluminum profile, such as conventional: O, T4, T5, T6 and so on3. How long is it within 100 degrees of heat? Continuous or intermittent entry, such as intermittent access, interval time, etc.4, the aluminum profile forming itself has a certain mechanical strength, such as tensile and yield and ductility, etc., but these mechanical strength is based on different materials (section shape) in different extrusion processing (T) Inferior.For example, a solid bar around 10MM, material 6061-T6, a short time into the furnace temperature of 100 degrees, the annealing temperature will make its hardness drops more quickly, then a long time will decrease, but no hardness.The material you say can not be deformed, the aforementioned points need to be clear, or any answer is biased, and I hope to help you!

- Q: How to process the wood grain transfer of aluminum profile? Thank you

- Popular talk is to transfer grain, electrostatic powder coating on metal material, vacuum equipment through the wood grain transfer on the coating material in high temperature, pay pressure, ink sublimation transfer printing or transfer film on the penetration into a conversion process in the coating. Now there are very good equipment in China ~!

- Q: Can aluminum profiles be used for staircases and handrails?

- Yes, aluminum profiles can be used for staircases and handrails. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for these applications. Additionally, aluminum profiles offer versatility in terms of design options and can be easily customized to suit specific requirements.

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

- Q: How many tons of aluminum can be produced by a ton of aluminium ingots?

- There are many factors to consider in this problem, and in the case of insufficient conditions, we can only compare them by using the hypothesis method. But personally think that a meal of aluminum ingots can definitely make a full or more than a ton of aluminum. The product is Aluminum Alloy, pure aluminum processed into Aluminum Alloy, so the process is sure to add other metal components (such as silicon, iron, copper, manganese, magnesium, zinc, chromium, titanium), assuming that the pure aluminum ingots is one hundred percent, so in the process of loss amount the amount of aluminum must be smaller than the metal, so the results will come out

- Q: Can aluminum profiles be used in load-bearing structures?

- Yes, aluminum profiles can be used in load-bearing structures. Aluminum is a lightweight and highly durable material that possesses excellent strength-to-weight ratio, making it suitable for various load-bearing applications. The profiles can be designed and manufactured to handle substantial loads, making them ideal for use in structures such as bridges, buildings, and industrial frameworks. Moreover, aluminum profiles have corrosion-resistant properties, which further enhances their suitability for load-bearing structures in various environments. However, it is essential to consider the specific design requirements, load conditions, and proper engineering calculations to ensure the aluminum profiles are appropriately sized and reinforced for the intended load-bearing purposes.

Send your message to us

Custom Cina Extruded Aluminum Profiles - Aluminum Profile 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords