Aluminum Baking Sheets Costco - Aluminium Sheet with Better Price and Stock Availability

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

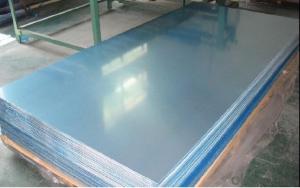

1.Structure of Product Description

aluminum sheet for hot rolled and alumnium coil for cold rolled is the best-selling grade in our chinese domestic market, which is also the ll widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,500mm*500mm, 2000mm*2000mm, etc.

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 100mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 13 tons/each size.

How many tons did you export in one year

USA, japan, UAE, Vietnam, Canada, etc.

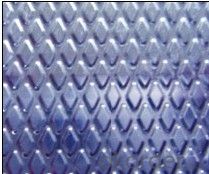

What is your basic products?

---Normally finish aluminium checkered plate/sheet/slab, aluminum casting coil,aluminum composite panel, aluminum sandwich panel, ACP, etc.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- If the thickness of the sheet is not enough, the effective thread stroke can be mounted with K nuts. Rivet nuts are required if accuracy is required.If it is a thick aluminum sheet, it can be directly drilled and tapped; also, the steel screw sleeve can be added.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Certainly! Nameplates or tags can be produced using 101 aluminum sheets. The durability, lightweight nature, and corrosion resistance of aluminum make it a popular material choice for such items. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability. This makes it suitable for various manufacturing processes like stamping, engraving, or etching. It can be easily cut, shaped, and customized to create nameplates or tags with clear and precise markings. Moreover, aluminum's ability to withstand harsh environments and its appealing appearance make it preferred across industries like automotive, aerospace, electronics, and signage. Hence, 101 aluminum sheets are a suitable material for producing nameplates or tags.

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: How do aluminum sheets perform in terms of magnetism or electromagnetic interference?

- Aluminum sheets have a very low magnetic permeability, which means they are not attracted to magnets and do not retain a magnetic field. This property makes aluminum sheets highly resistant to magnetism and reduces their susceptibility to electromagnetic interference (EMI). Aluminum is often used in applications where shielding against EMI is necessary, such as in electronic devices, aerospace structures, and electrical enclosures. Due to its non-magnetic nature, aluminum sheets do not interfere with magnetic fields or create any significant electromagnetic fields of their own. This makes them ideal for applications that require minimal magnetic distortion, such as in MRI machines or sensitive scientific instruments. In addition to their low magnetism, aluminum sheets also have good electrical conductivity. This property allows them to effectively dissipate any induced currents or static charges, further reducing the risk of electromagnetic interference. Overall, aluminum sheets perform excellently in terms of magnetism and electromagnetic interference. Their low magnetic permeability, non-magnetic nature, and good electrical conductivity make them a favorable choice for applications where EMI shielding and minimal magnetic distortion are essential.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are highly suitable for signage applications due to their durability, lightweight nature, and ability to withstand various weather conditions. They are also easy to customize, making them a popular choice for both indoor and outdoor signage.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

- Q: What are the different methods for cutting aluminum sheets?

- Aluminum sheets can be cut using various methods that are commonly employed. 1. Shearing: To make a straight cut through the aluminum sheet, a sharp blade is used in this method. Shearing is typically used for thinner sheets and results in clean and straight cuts. 2. Sawing: Another method for cutting aluminum sheets is sawing. It involves the use of a saw blade with small teeth to cut through the material. Sawing can be done manually or with the assistance of power tools like band saws or circular saws. 3. CNC Machining: For highly precise cutting of aluminum sheets, Computer Numerical Control (CNC) machining is employed. This method utilizes a computer-controlled machine that follows programmed instructions to achieve the desired shape. CNC machines are capable of creating complex cuts and shapes with great accuracy. 4. Laser Cutting: A non-contact method, laser cutting, employs a high-powered laser to cut through aluminum sheets. The laser beam melts or vaporizes the aluminum, resulting in a clean and precise cut. Laser cutting is commonly used for intricate designs and offers a high level of precision. 5. Waterjet Cutting: Waterjet cutting involves the use of a high-pressure jet of water mixed with an abrasive substance to cut through aluminum sheets. This method is versatile and can be used for various materials and thicknesses. It produces clean cuts without generating heat, making it suitable for heat-sensitive materials as well. 6. Plasma Cutting: Plasma cutting utilizes a high-temperature plasma arc to cut through aluminum sheets. The plasma arc melts the metal and blows away the molten material, creating the desired cut. This method is commonly used for thicker aluminum sheets and can be done manually or with the assistance of CNC machines. These different cutting methods offer varied precision levels, speeds, and suitability for different sheet thicknesses and designs. The choice of cutting method depends on factors such as the desired cut quality, aluminum sheet thickness, and specific project requirements.

Send your message to us

Aluminum Baking Sheets Costco - Aluminium Sheet with Better Price and Stock Availability

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords