Costco Aluminum Foil Sheets - Aluminium Slab with Best Discount Price in Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

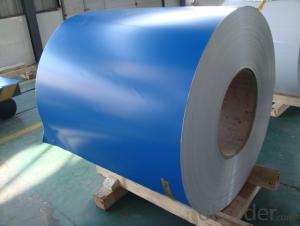

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1500*4000, 1500*3000,1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from fiji, uae, saudi arabia,England, SINGAPORE, ETC.

What is your mainly products?

---Normally they are cold rolled sheet, hot rolled sheet,checkered sheet with big-5-bar pattern, aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- I believe the fence techs are mistaken. On an electric fence, the wire is basically bare, and the periodic 10 kV shocks are very low current. Aluminum is cheap, and once it develops surface oxidation, will last. Copper would last, too - it would just cost more. For photovoltaic panels, copper is almost always the wire of choice. At #8 or larger, use stranded, of course. Copper has less resistance, which will be important in low-voltage PV. Also, aluminum wire cannot be simply put into fittings designed for copper; it must use special fittings designed for aluminum, or connected to copper with a wire nut and antioxidant.

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Alright - first, find the number of moles of aluminium in that sample, by dividing the mass (0.47g) by the molecular weight of aluminium (26.98). Then, having obtained the number of moles, multiply it by the avogadro's constant (6.023x1023) and you will obtain the number of atoms, and by dividing the mass by the number of atoms, you get the mass of an individual atom.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are suitable for aircraft manufacturing. Aluminum is widely used in the aerospace industry due to its unique combination of properties such as lightweight, high strength, corrosion resistance, and excellent formability. These characteristics make aluminum an ideal material for constructing various aircraft components, including fuselages, wings, and structural parts. Additionally, aluminum alloys can be easily joined, allowing for efficient manufacturing processes. Overall, aluminum sheets play a crucial role in aircraft manufacturing, contributing to the overall performance, durability, and safety of the aircraft.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Can aluminum sheets be used together with other materials, specifically insulation materials?

- <p>Yes, aluminum sheets can be used in combination with other materials, including insulation materials. Aluminum is often used as a cladding material due to its durability and resistance to corrosion. When combined with insulation materials, it can enhance the thermal performance of a structure by reducing heat transfer. This combination is common in construction and roofing applications, where aluminum sheets can provide a protective outer layer while the insulation material manages thermal control. The use of aluminum with insulation materials can lead to energy-efficient buildings and improved indoor comfort.</p>

- Q: What is the maximum temperature aluminum sheets can withstand?

- The ability of aluminum sheets to tolerate high temperatures is influenced by various factors, such as the composition and thickness of the alloy, as well as the specific application and environment. Pure aluminum, in general, has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), but its strength and rigidity decrease at lower temperatures. Commercial aluminum alloys, on the other hand, have higher melting points and can endure greater temperatures. For instance, the melting point of 6061 aluminum alloy is roughly 580 degrees Celsius (1076 degrees Fahrenheit), while the melting point of 7075 aluminum alloy is slightly higher at around 640 degrees Celsius (1184 degrees Fahrenheit). Nevertheless, it is important to highlight that the maximum temperature that aluminum sheets can handle without significant distortion or structural harm may be lower than their melting point. This is due to the fact that aluminum's mechanical properties and strength deteriorate at elevated temperatures. When using aluminum sheets in applications involving high temperatures, it is crucial to consider the specific alloy and its thermal characteristics, as well as any potential alterations in strength, hardness, or other pertinent properties that may occur at elevated temperatures. Consulting material specifications, engineering guidelines, or seeking advice from metallurgical experts can provide more accurate and specific information regarding the maximum temperature capabilities of aluminum sheets for a particular application.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

- Q: why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

Send your message to us

Costco Aluminum Foil Sheets - Aluminium Slab with Best Discount Price in Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords