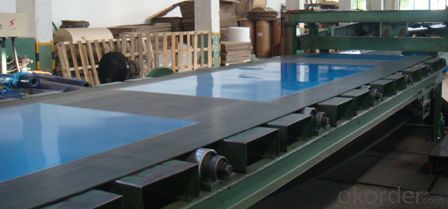

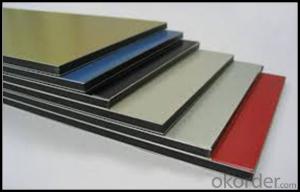

Aluminium Plain Sheet for Composite Pannel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Supplier Aluminium Sheet

1.Thickness:0.3-150mm

2.Width:500-1950mm

3.Temper: O,H12,H22,H14,H24,H16,H26

Supplier Aluminium Sheet

Henan Xindatong Aluminum Industry Co.,Ltd.

Company Tel:+86 0371 63965568 Mr. Bert Wang

Company Fax:+86 0371 60220063

Xindatong Aluminum specializes in manufacturing Aluminum sheets,aluminum coils

(1)we have the certiificate of ISO 9002; SGS cerificate.

(2) our quality is based on EN,ASTM,JIS.

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC |

4.0-150 | 1000-1900 | H112,H111 | DC | ||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC |

4.0-150 | 1000-1900 | H112,H111 | DC | ||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC |

4.0-150 | 1000-1900 | H112, H111 | DC | ||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC |

- Q: How is aluminum sheet made?

- Aluminum sheet is made through a process called rolling, which involves passing a preheated aluminum ingot through a series of rolling mills. The initial step is the heating of the ingot to a specific temperature to make it more malleable. Once heated, the ingot is then passed through a series of rolling mills, where it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it is compressed and elongated, resulting in a thinner and longer sheet. The process is repeated multiple times, with each pass reducing the thickness of the sheet further. To maintain the desired thickness and dimensions, the sheet is periodically annealed, which involves heating it to a specific temperature and then slowly cooling it. This annealing process helps relieve internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that can be used in a wide range of applications, from construction and automotive industries to packaging and electrical appliances.

- Q: Can aluminum sheets be easily formed or bent?

- Aluminum sheets possess the ability to be effortlessly formed or bent. The metal known as aluminum is remarkably pliable, signifying that it can be shaped into countless configurations without succumbing to fractures or breakages. This characteristic renders aluminum sheets exceedingly sought-after in sectors like automotive, aerospace, and construction, where the demand for intricate shapes and designs is paramount. Aluminum's pliability facilitates effortless manipulation via methods such as rolling, pressing, or bending, thereby empowering the fabrication of elaborate and tailor-made items. Furthermore, owing to aluminum's lightweight nature and remarkable strength-to-weight ratio, it stands as an ideal material for applications necessitating forming or bending, as it can be molded without adding excessive heft to the ultimate product.

- Q: Can the aluminum sheets be used for manufacturing architectural sunshades?

- Yes, aluminum sheets can be used for manufacturing architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in the construction industry for various purposes, including sunshades. It offers excellent resistance to corrosion and can withstand outdoor exposure, making it suitable for architectural applications. Additionally, aluminum sheets can be easily customized and fabricated into different shapes and sizes, allowing for flexibility in design.

- Q: Can aluminum sheets be used for interior design purposes?

- Certainly, aluminum sheets are a great option for interior design purposes. The versatility of aluminum as a material offers numerous advantages when it comes to interior design applications. Its lightweight nature, durability, and resistance to corrosion make it an excellent choice for various design elements like wall coverings, ceiling panels, backsplashes, and room dividers. Aluminum sheets can be easily tailored and shaped into different forms, sizes, and finishes, providing limitless design possibilities. Moreover, aluminum is an environmentally-friendly material as it can be highly recycled. Its sleek and contemporary appearance adds a modern touch to any interior design project. In summary, aluminum sheets have gained popularity among interior designers due to their practicality, visual appeal, and sustainable nature.

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- Take a look on this website. You will see some of the main uses of aluminium and will be able to determine what it is capabke of: www.bwcaluminium .uk

- Q: Can aluminum sheet be used for electrical conductivity applications?

- Yes, aluminum sheet can be used for electrical conductivity applications. Aluminum has good electrical conductivity properties, making it suitable for various electrical applications such as wiring, connectors, and conductive components.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are several different types of alloys used for powder-coated aluminum sheets, each with its own unique set of properties and characteristics. Some of the most commonly used alloys include: 1. 3003 Alloy: This alloy is one of the most widely used for powder-coated aluminum sheets. It offers good corrosion resistance, excellent formability, and high strength. It is often used in applications that require moderate strength and resistance to atmospheric corrosion, such as building facades, signage, and automotive parts. 2. 5052 Alloy: This alloy is known for its high strength and excellent corrosion resistance. It is often used in marine and architectural applications where durability and resistance to saltwater and harsh environments are essential. It is also commonly used in the manufacturing of electrical enclosures and transportation equipment. 3. 6061 Alloy: This alloy is highly versatile and offers excellent weldability, formability, and machinability. It is often used in a wide range of applications, including aerospace components, marine hardware, structural components, and automotive parts. It has good corrosion resistance and can be easily powder-coated to enhance its appearance and provide additional protection. 4. 7075 Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although it is less commonly used for powder-coated aluminum sheets due to its higher cost, it can still be found in certain specialized applications. These are just a few examples of the different types of alloys used for powder-coated aluminum sheets. The choice of alloy depends on the specific requirements of the application, including factors such as strength, corrosion resistance, formability, and cost.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q: why intact aluminum sheet stop quicker than pectinate one in the magnetic field?

- while swinging in the magnetic field, intact aluminum sheets will formulate inner eddy current,that is the annular induced current.eddy current will transform the mechanical energy into heat energy, which makes the aluminum sheet stop quickly.but pectinate aluminum sheet can't formulate intact eddy current, so intact aluminum sheet stop quicker than pectinate one.

- Q: What are the common thicknesses of aluminum sheets used in construction?

- The common thicknesses of aluminum sheets used in construction vary depending on the specific application and requirements. However, some commonly used thicknesses include 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are often used for architectural applications such as wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), are also used in heavier construction applications such as structural components, support beams, and decking. It is important to note that these thicknesses are just examples and can vary depending on the specific project requirements and engineering specifications.

Send your message to us

Aluminium Plain Sheet for Composite Pannel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords