Heavy Aluminum Baking Sheets - Aluminum Mirror Sheet with Better Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

hot rolled and cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 3105, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,O, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

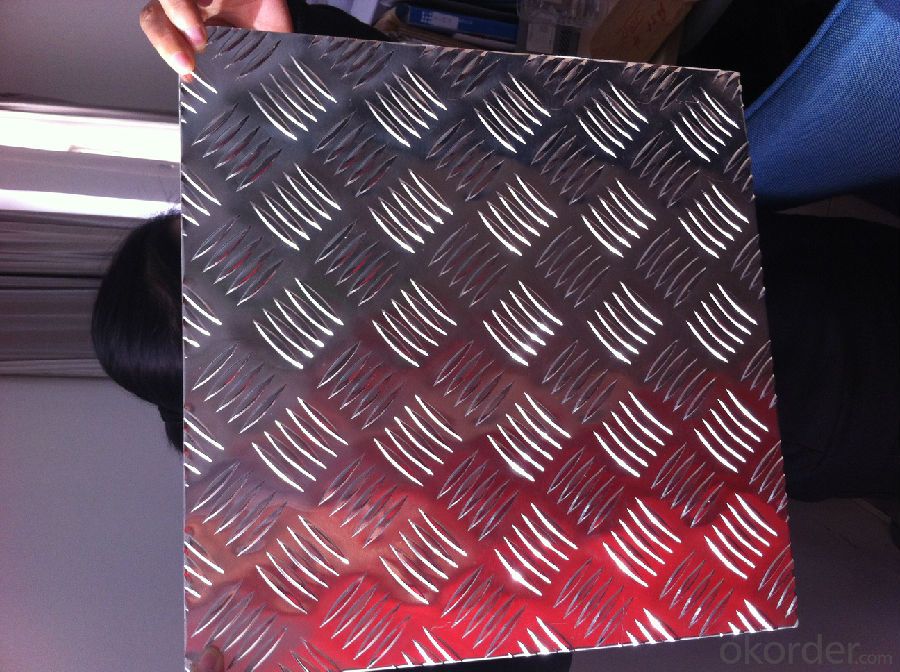

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 20mm to 2500mm, etc.

What is the length range:

---It is from 800mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 4 tons/each size.

How many tons did yoport in one year?

---Normally it is around 6000 tons totally.

Where is your client from?

---Normally it is from products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkere sheetcasting coil, etc.

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- The problem is that in an oxygen rich environment, like the air, then aluminum will instantly form a protective coating of aluminum oxide on any freshly prepared surface. So, mechanical sanding or abrasion will be of little help. You could abrade the surface inside of a container where there is no oxygen. That would require the construction of an airtight glovebox, then fill it with N2 or an inert gas. The aluminum oxide coating will dissolve in very basic solutions. Aluminum metal is also very reactive with water. 2Al + 6H2O -- 2Al(OH)3(s) + 3H2(g) In Drano, the basic solution dissolves the Al2O3 coating, which allows the Al metal to react with water producing H2 gas and the agitation needed to help dissolve the clog.

- Q: What are the environmental benefits of using aluminum sheets?

- The usage of aluminum sheets is associated with numerous environmental advantages. To begin with, aluminum is a highly recyclable substance, meaning it can be recycled repeatedly without losing its quality or properties. This diminishes the need for mining and extracting new aluminum ore, which can lead to deforestation, destruction of habitats, and pollution of water and air. The recycling of aluminum sheets also demands much less energy compared to the production of new ones, resulting in reduced emissions of greenhouse gases and a smaller carbon footprint. Moreover, aluminum sheets are lightweight, making them a more sustainable option in comparison to materials like steel or plastic. Their utilization in various industries like automotive and aerospace can aid in reducing the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This becomes particularly crucial in the context of climate change and the necessity to decrease our reliance on fossil fuels. Additionally, aluminum is resistant to corrosion, durable, and long-lasting, making it a sustainable choice for various applications. Its durability lessens the need for frequent replacements, thereby reducing waste generation. Furthermore, aluminum sheets can be employed in construction to enhance insulation, resulting in energy savings and diminished emissions of greenhouse gases. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This renders it a safe material option for various applications, including food packaging and medical equipment. To summarize, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By selecting aluminum sheets over other materials, we can contribute to the reduction of resource extraction, energy consumption, emissions of greenhouse gases, and generation of waste, while promoting a more sustainable and eco-friendly future.

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent due to their malleability and low density.

- Q: How do aluminum sheets compare to other metals?

- Aluminum sheets have several advantages when compared to other metals. Firstly, aluminum is very light in weight, making it an ideal choice for applications where weight is a concern, such as in the aerospace industry. Additionally, aluminum is highly resistant to corrosion, which means it can withstand exposure to moisture and chemicals without deteriorating. This makes aluminum sheets suitable for outdoor use and in environments with high humidity or corrosive substances. Moreover, aluminum has excellent conductivity, both thermal and electrical. This makes it a popular choice for heat sinks, electrical enclosures, and other applications that require efficient heat dissipation or electrical conduction. Furthermore, aluminum sheets can be easily shaped and formed, giving them versatility in various manufacturing processes. They can be bent, cut, welded, and machined with relative ease, making them highly adaptable to different design specifications. In terms of cost, aluminum is generally more affordable compared to other metals like steel or copper. This makes it a cost-effective option for many industries, especially for large-scale production or projects with budget constraints. However, it is important to note that aluminum sheets may not be suitable for applications that require high strength or extreme temperatures, as aluminum has lower strength and melting point compared to certain other metals. In such cases, metals like steel or titanium may be more appropriate. In summary, aluminum sheets offer a combination of lightweight, corrosion resistance, good conductivity, versatility, and affordability that makes them a preferred choice in many industries. However, the specific requirements of a project or application should be considered to determine if aluminum sheets are the best fit or if another metal would be more suitable.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- The difference is as follows: 1, different layers: single aluminum plate is divided into two layers, the surface layer is aluminum skin, second layers of plastic, aluminum plate is divided into three layers: the surface layer and the third layer is an aluminum sheet, the middle is plastic, or aluminum plate than single aluminum plate a layer of aluminum skin; 2, the quality of different because: aluminum sheet aluminum plastic board less than a layer of aluminum skin, so the single aluminum plate than the aluminum plate quality will certainly be worse; 3, the price is different: single aluminum plate is cheaper than aluminum plate, aluminum plate positioning for low-grade, aluminum-plastic plate according to the quality and thickness of plastic and aluminum skin into the middle different grades, but certainly more than the single aluminum plate and expensive; 4, the construction effect is certainly not the same: a plastic plate can be slotted, bending turning construction construction, suitable for a variety of occasions, but not the single aluminum plate slot, bending, and because the bottom is plastic, such as plastic bonding effect Board.

- Q: after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: Are aluminum sheets suitable for mold making?

- No, aluminum sheets are not suitable for mold making as they lack the flexibility and malleability required for creating intricate shapes and designs. Mold making typically requires materials like silicone or rubber that can capture fine details and easily release the molded object.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Aluminum sheets, indeed, prove to be a suitable choice for artistic sculptures. Boasting versatility, aluminum offers numerous benefits for sculpting endeavors. First and foremost, its lightweight nature makes it easier for artists to handle and manipulate. This quality grants them the ability to fashion intricate and detailed sculptures without compromising on structural integrity. Moreover, aluminum possesses high malleability, allowing it to be molded into diverse forms and contours. This grants artists the freedom to experiment with various designs and achieve their desired artistic expression. Additionally, aluminum's resistance to corrosion and weathering makes it an ideal material for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and maintain its aesthetic appeal over time. Furthermore, aluminum sheets can be effortlessly welded or joined together, enabling artists to create larger and more intricate sculptures. All in all, aluminum sheets furnish artists with a flexible and long-lasting material that nurtures creativity and guarantees longevity in their sculptural masterpieces.

- Q: How is the thickness of aluminum sheets measured?

- The thickness of aluminum sheets is typically measured using a device called a micrometer or caliper. These instruments accurately measure the distance between two opposite sides of the sheet, providing an accurate measurement of its thickness.

Send your message to us

Heavy Aluminum Baking Sheets - Aluminum Mirror Sheet with Better Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords