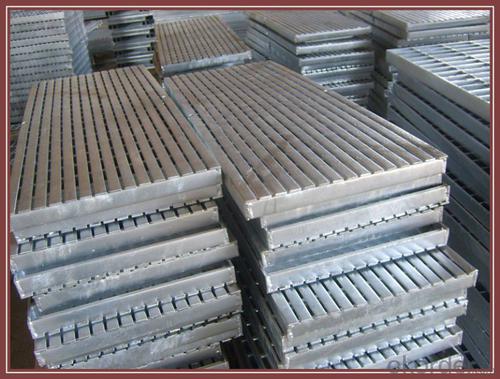

Brushed Aluminum Sheets Houston Aluminum Alloy Grating Staircase/Stair Tread/Stair Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

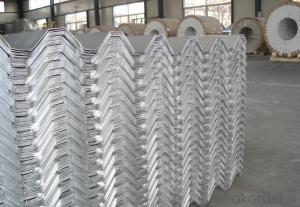

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

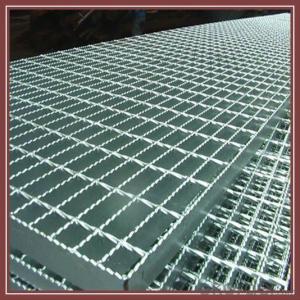

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- while I've never done it, my brother in law painted their aluminum siding. He used paint he bought at sears- go to a paint store, one that only sells paint and pick their brains. He power washed the house, primed it and used a sprayer to apply both the paint and the primer....the house looks like they replaced the siding.

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: How do aluminum plates paint?

- Pretreatment is usually required. Acid and alkali cleaning can be done either by oil or by xylene,The paintings do not know, but most of them are painted or printed on the aluminum plate, usually by heat transfer, silk screen, or decorative board, which is sprayed directly and then painted.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Can aluminum sheets be easily formed into different shapes?

- Aluminum sheets possess the capability to assume diverse forms with ease. Being an exceedingly flexible metal, aluminum can be effortlessly curved, stretched, and shaped without experiencing any cracks or fractures. This property renders aluminum a favored choice across numerous industries, ranging from automotive and aerospace to construction and manufacturing. Utilizing a variety of techniques such as bending, rolling, stamping, and deep drawing, aluminum sheets can be transformed into intricate and intricate designs. Moreover, owing to its lightweight nature, aluminum proves even more manageable during the formation process, requiring less force and energy. Consequently, aluminum sheets exhibit tremendous versatility and adaptability, rendering them exceptionally suitable for the creation of various shapes and structures.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The price of 101 aluminum sheets is typically lower compared to other aluminum alloys.

- Q: What kind of aluminum sheet is most suitable for constructing the exterior walls of a building?

- <p>The best type of aluminum sheet for building exterior walls is typically aluminum composite material (ACM) or aluminum coil coated with a protective layer. ACM is lightweight, durable, and offers excellent resistance to weather and corrosion. It also provides good thermal insulation and is easy to install. Coated aluminum coils are often used for cladding due to their strength, low maintenance, and longevity. The choice may also depend on specific project requirements, such as aesthetic considerations, budget, and local climate conditions.</p>

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications. 101 aluminum is a commercially pure aluminum alloy that has low electrical conductivity. It is not able to efficiently conduct heat, making it unsuitable for applications where heat transfer is desired. For conductive heat transfer applications, it is better to use alloys that have higher thermal conductivity, such as 6061 or 7075 aluminum. These alloys have better heat transfer properties and are commonly used in heat sinks, heat exchangers, and other applications where efficient heat transfer is required.

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

Send your message to us

Brushed Aluminum Sheets Houston Aluminum Alloy Grating Staircase/Stair Tread/Stair Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords