Aluminum Sheets Miami - Aluminum Gratings/Grates/Grate Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

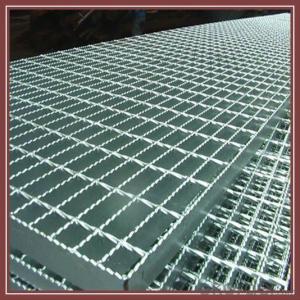

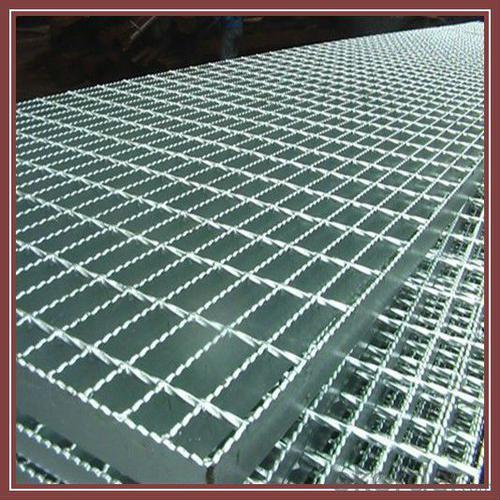

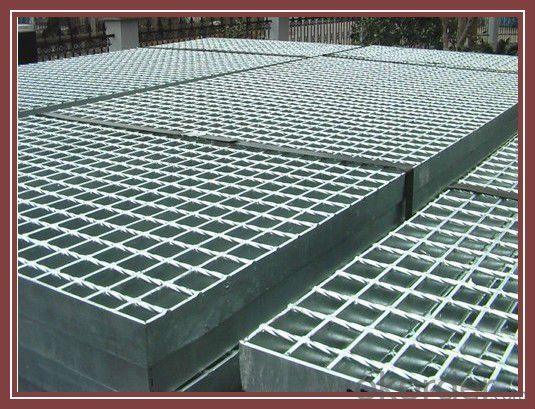

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

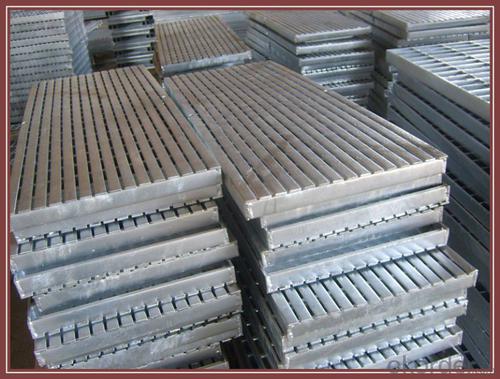

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for automotive wheels?

- Yes, aluminum sheets are suitable for automotive wheels. Aluminum offers several advantages such as being lightweight, corrosion-resistant, and providing better heat dissipation. These qualities make aluminum sheets a popular choice for manufacturing automotive wheels as they contribute to improved fuel efficiency and overall performance of the vehicle.

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q: Can aluminum sheets be used for electrical applications?

- Indeed, aluminum sheets find utility in electrical applications. Renowned for its exceptional conductivity, aluminum boasts nearly 60% of copper's electrical conductivity. This renders it suitable for diverse electrical applications, ranging from wiring and bus bars to transformers and electrical panels. Owing to their lightweight and resistance to corrosion, aluminum sheets are frequently employed in the fabrication of electrical enclosures and housings. Furthermore, aluminum emerges as a cost-effective alternative to other metals, such as copper, thereby solidifying its reputation as a favored selection in numerous electrical applications.

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: What industries use aluminum sheets?

- Aluminum sheets find extensive use across various industries due to their numerous advantageous properties. The automotive industry, in particular, heavily relies on aluminum sheets. With its lightweight yet strong composition, aluminum proves to be an ideal material for manufacturing car bodies and parts. This, in turn, helps reduce vehicle weight, improving fuel efficiency and curbing emissions. Similarly, the aerospace industry also heavily depends on aluminum sheets owing to their high strength-to-weight ratio. Aluminum's suitability for aircraft construction is evident in its usage for airplane frames, wings, and fuselages. The lightweight nature of aluminum contributes to increased fuel efficiency and enables larger payloads. The construction industry is another major consumer of aluminum sheets. Thanks to its corrosion resistance and durability, aluminum serves as an excellent choice for building materials. It finds common application in roofing, siding, windows, doors, and structural components for both residential and commercial construction projects. In the packaging industry, aluminum sheets are extensively utilized for manufacturing beverage cans. Aluminum cans provide a lightweight and portable packaging solution while ensuring product freshness and protection against light and air. Additionally, the electrical industry benefits from the use of aluminum sheets. Aluminum's excellent conductivity makes it well-suited for electrical transmission lines, cables, and wiring. It also finds application in the production of heat sinks and electrical enclosures. Marine industry applications involve aluminum sheets for boat building and ship construction due to their resistance to corrosion in saltwater environments. Furthermore, aluminum sheets play a significant role in the manufacturing of household appliances, such as refrigerators, ovens, and washing machines, owing to their durability, lightweight nature, and heat conductivity properties. In conclusion, the versatility, strength, lightweight nature, and corrosion resistance of aluminum sheets make them indispensable across a wide range of industries, including automotive, aerospace, construction, packaging, electrical, marine, and household appliances.

- Q: I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- OK - first you need the ENTIRE mass of the aluminum nitrate (gram formula mass). You need the correct formula for aluminum nitrate, then add up the atomic masses from the periodic chart. Then, you need to convert 3.99 g of aluminum nitrate to moles of aluminum nitrate. (grams/formula mass = moles) Then, you need to take into account how many moles of nitrate ions are in a mole (look at the correct formula for aluminum nitrate). Then multiply by the number of moles you calculated (moles of ions per molecule x #moles). This would be moles of ions. You need individual ions you would the multiply by 6.02 x 10^23 ions/mole. SO: grams of sample divided by formula mass x #nitrate ions per molecule x (6.023 x 10^23 ions per mole) = # ions

- Q: Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is a highly efficient conductor of heat, making it an ideal material for heat exchangers. Its high thermal conductivity allows for excellent heat transfer between fluids, resulting in efficient heat exchange. Additionally, aluminum sheets are lightweight, corrosion-resistant, and have good mechanical properties, further contributing to their suitability for heat exchanger applications.

- Q: Are aluminum sheets suitable for chemical filtration applications?

- Yes, aluminum sheets are suitable for chemical filtration applications. Aluminum is resistant to corrosion, making it an ideal material for filtering chemicals. It is also lightweight and has high thermal conductivity, allowing for efficient heat transfer during filtration processes.

- Q: Are the aluminum sheets recyclable?

- Yes, aluminum sheets are highly recyclable. Aluminum is one of the most recyclable materials on the planet, and it can be recycled indefinitely without losing its quality. Recycling aluminum sheets requires less energy compared to producing new aluminum from raw materials, which has significant environmental benefits. The recycling process involves melting down the aluminum sheets to extract the metal, which can then be used to produce new aluminum products. Recycling aluminum sheets not only conserves valuable resources but also helps reduce greenhouse gas emissions and landfill waste. Therefore, it is highly recommended to recycle aluminum sheets whenever possible.

Send your message to us

Aluminum Sheets Miami - Aluminum Gratings/Grates/Grate Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords