500 Sheets of Aluminum Foil 9 In - Anti-Corrosion and High Strength Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

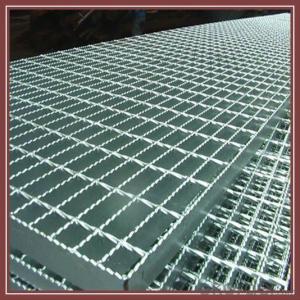

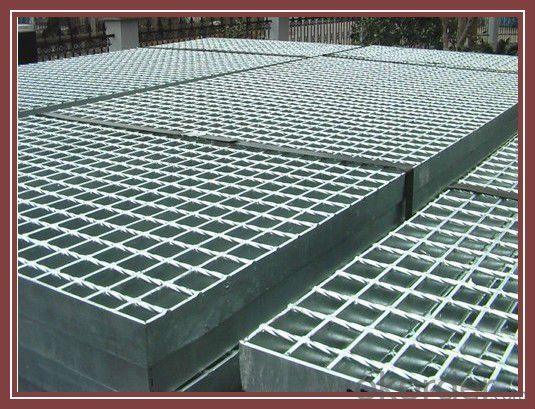

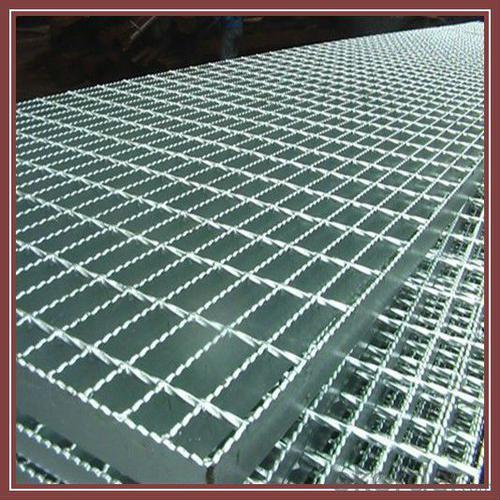

3.Drainage trench coverImages:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets are widely recognized for their remarkable flexural strength properties. Their inherent structural integrity and high strength-to-weight ratio allow them to endure bending forces without experiencing significant deformation or failure. The flexural strength of aluminum sheets is subject to variation based on factors like the chosen alloy, temper, and sheet thickness. Nevertheless, aluminum sheets are generally acknowledged for their impressive resistance to bending and ability to withstand applied loads without buckling or breaking. Consequently, aluminum sheets find extensive application in industries such as construction, automotive, aerospace, and marine, where components must endure flexural stresses. Furthermore, the flexural strength of aluminum sheets can be further enhanced through the utilization of diverse fabrication techniques and alloying elements, thereby optimizing their suitability for specific applications.

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- more mass is 10kg of aluminum, grams is the unit for mass, more mass more grams, density depends on its volume and mass, which you havent provided its volume

- Q: which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- aluminum okorder / so what you are finding is that aluminum will melt before the copper or brass...

- Q: What is the fatigue limit of aluminum sheets?

- The fatigue limit of aluminum sheets refers to the maximum stress level at which the material can endure an infinite number of cyclic loadings without experiencing fatigue failure. Aluminum has a relatively high fatigue limit compared to other materials, which means it can withstand a significant number of load cycles before fatigue failure occurs. However, it is important to note that the fatigue limit of aluminum sheets can vary depending on factors such as the alloy composition, heat treatment, and surface conditions. Therefore, it is crucial to consider these factors and conduct proper testing to determine the specific fatigue limit of a particular aluminum sheet.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q: Characteristics of anodized aluminium plate

- (5) strong pollution resistance: no fingerprints, but also traces of dirt, easy to clean, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall, aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc..

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Yes, aluminum sheets are suitable for manufacturing kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to rust and corrosion, making it ideal for use in kitchen environments. Additionally, aluminum sheets can be easily cut and shaped to fit various design preferences, providing a sleek and modern look to any kitchen backsplash.

Send your message to us

500 Sheets of Aluminum Foil 9 In - Anti-Corrosion and High Strength Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords