Painted Aluminum Sheets Houston - Many Kinds of Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

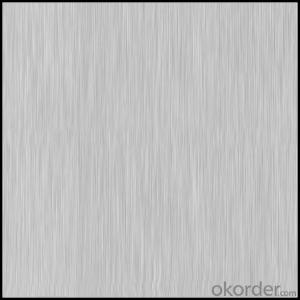

SURFACE QUALITY: GOOD APPEARANCE WITH NO-CRACK AND WELL-DISTRIBUTE GRAIN.

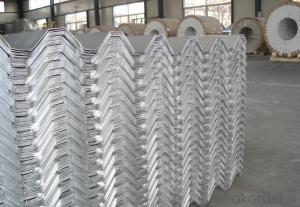

BUILD UP: TIGHT SLIT EDGES FREE FROM CRACKS, LAYER TO LAYER SHIFT NOT MORE THAN 2MM.

PROFILE: -0/+1%

FLATNESS: MILL FLATNESS COIL HAVING EDGE WAVINESS RATHER THAN CENTER BUCKLES SHALL BE ACCEPTABLE.

ROLLING PERFORMANCE: RE-ROLLABLE TO THE FINAL DESIRES GAUGES

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: What are the different machining options for aluminum sheets?

- Some of the different machining options for aluminum sheets include cutting, drilling, milling, turning, and bending. These processes can be performed using various tools such as saws, drills, milling machines, lathes, and press brakes. Additionally, laser cutting and waterjet cutting are also common methods used for machining aluminum sheets.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets are commonly used in aerospace industries. Aluminum is a lightweight and corrosion-resistant material that possesses excellent strength-to-weight ratio, making it ideal for various aerospace applications. It is used in the construction of aircraft structures, such as wings, fuselage, and landing gear, due to its ability to withstand high stress and pressure. Additionally, aluminum sheets are easily formable and can be fabricated into complex shapes, contributing to the design flexibility required in the aerospace industry. However, it is important to note that aluminum alloys are typically used in aerospace applications rather than pure aluminum, as they offer enhanced mechanical properties and improved performance.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

Send your message to us

Painted Aluminum Sheets Houston - Many Kinds of Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords