Aluminum Sheets for Ceilings - Aluminum Gratings/Grid Platform for Work Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

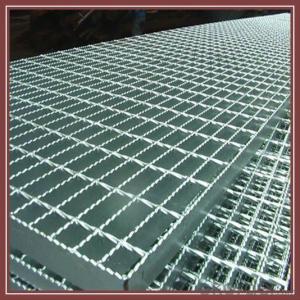

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different surface finishes available for aluminum sheet?

- There are several different surface finishes available for aluminum sheet, each offering unique aesthetic and functional properties. Some of the common surface finishes for aluminum sheet include: 1. Mill Finish: This is the most basic and widely used surface finish for aluminum sheet. It has a smooth, raw appearance with visible grain lines from the manufacturing process. 2. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a pattern of fine lines. It provides a satin-like appearance and is often used for decorative purposes. 3. Anodized Finish: This finish is created through an electrochemical process called anodizing, which forms a durable oxide layer on the surface of the aluminum sheet. Anodized finishes are available in various colors and offer enhanced corrosion resistance. 4. Polished Finish: This finish involves polishing the aluminum sheet to a high gloss or mirror-like surface. It provides a reflective and elegant appearance, making it suitable for decorative applications. 5. Embossed Finish: This finish involves embossing patterns or textures onto the surface of the aluminum sheet. It adds texture and visual interest to the sheet, making it ideal for architectural and decorative purposes. 6. Powder Coated Finish: In this finish, a dry powder is applied to the surface of the aluminum sheet and then heated to form a protective and decorative coating. Powder coated finishes are available in a wide range of colors and offer excellent durability and resistance to weathering. These are just a few of the many surface finishes available for aluminum sheet. The choice of finish depends on the intended application, desired appearance, and specific performance requirements.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- put pans in sink boil some water with cream of tartar and pour on pans allow to soak as water cools scrub pans should take care of issues

- Q: or aluminum ? and what other gases are released?

- Aluminium does not normally react with water because of a surface coating of the highly unreactive Al2O3 that forms on exposure to atmospheric oxygen. In the presence of strong base, however, this compound dissolves due to complexation by hydroxide, similarly to how silver chloride dissolves in ammonia. Al2O3(s) + 2OH-(aq) + 3H2O(l) ----- 2[Al(OH)4]-(aq) Once this has occured, aluminium metal, a very strong reducing agent, is exposed to water. 2Al(s) + 6H+(aq) ----- 2Al3+(aq) + 3H2(g) Even though the solution is alkaline, there is still a low concentration of H+ formed by the autoprotolytic dissociation of water. The Al3+ formed then reacts with hydroxide to produce more [Al(OH)4]-. Yes, the hydrogen gas is from the water.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a versatile material that offers several benefits for sporting equipment. It is lightweight, which is crucial for many sports equipment like bicycles, tennis rackets, and baseball bats, as it allows for easier handling and maneuverability. Additionally, aluminum is corrosion-resistant, ensuring the longevity of the sporting goods even when exposed to various weather conditions. It also provides excellent strength-to-weight ratio, making it suitable for high-performance equipment that requires durability without adding unnecessary weight. Therefore, 101 aluminum sheets can be a viable choice for manufacturing various sporting goods, providing the desired properties needed for performance, longevity, and user experience.

- Q: What are the safety standards for using aluminum sheets in construction?

- <p>Yes, there are safety standards related to using aluminum sheets in construction projects. These standards ensure the material's structural integrity, durability, and safety. They include specifications for thickness, strength, and quality of aluminum sheets, as well as guidelines for their installation to prevent issues like corrosion, fire hazards, and structural failure. Compliance with these standards is crucial for the safety of the construction workers and the longevity of the building.</p>

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- If this is your first bow, I'd say go aluminum. Get the Platinum Plus from Easton, much cheaper and a hell of a lot better build than carbon arrows twice its price. The key with aluminum is to choose shafts with thick walls. When you look at the shaft sizes, you have a 4 digit number. The first 2 digits represents the outer diameter of the shaft, while the second 2 digits represents the wall thickness. With Plats, you want to get something with a 16 wall thickness. That's 16/1000, so 1516 or 1716 etc. The size/stiffness of these shafts will depend on 2 major factors, and 1 not so major one. The major factors are drawlength and draw weight at that drawlength. The one other factor is the bow design and material. Certain newer top end limbs will be so fast that they need stiffer arrows compared to older bows of the same drawweight. Now, carbon shafts, carbon shafts break yes, but it's your responsibility to make sure before you shoot to check for micro cracks. To do that, you bend the arrow and turn the shaft while listening for cracking noises. Well built carbon shafts will last a very long time, but well built carbon arrows are also at least 3 times more expensive than the Plats. Some durable arrows include the Gold Tip, and the Carbon Express. Not all carbon arrows are built to be durable mind you. Some are built for speed sacrificing durability. So, my vote is get yourself a set of Platinums, these shafts, while cheap had been the world record holder for a rather long time at 18m and 25m.

Send your message to us

Aluminum Sheets for Ceilings - Aluminum Gratings/Grid Platform for Work Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords