Custom CNC Processed Aluminum Channel Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Profile of Custom CNC Processing Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile of Custom CNC Processing:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

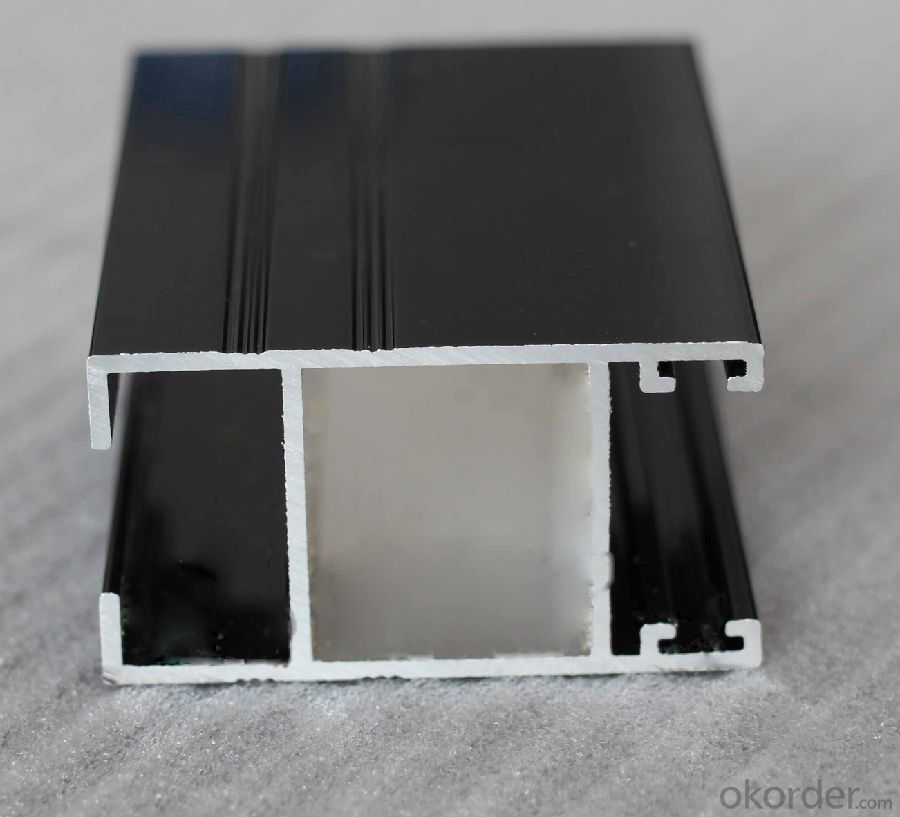

3.Aluminum Profile of Custom CNC Processing Images:

4.Aluminum Profile of Custom CNC Processing Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the impact resistance properties of aluminum profiles?

- Aluminum profiles have excellent impact resistance properties due to their inherent strength and durability. They can withstand high impact forces without deforming or breaking, making them suitable for various applications where impact resistance is crucial, such as automotive, construction, and aerospace industries. Additionally, aluminum profiles can absorb and distribute impact energy effectively, minimizing the risk of damage or injury.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the construction or design of staircases.

- <p>Aluminum profiles for staircases are diverse and serve different functions. Common types include: 1. Handrail profiles, which provide support and safety. 2. Stringer profiles, forming the backbone of the staircase. 3. Tread profiles, which are the horizontal surfaces on which one steps. 4. Riser profiles, covering the vertical space between steps. 5. Baluster profiles, used as vertical supports between handrails and treads. 6. Connector profiles, for joining different parts of the staircase. Each type is designed to withstand specific loads and is chosen based on the staircase's design, weight capacity, and aesthetic requirements.</p>

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can be used for modular storage systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including storage and shelving systems. Its versatility allows for easy customization and the ability to create modular units that can be easily assembled, disassembled, and reconfigured as needed. Additionally, aluminum profiles provide a sleek and modern aesthetic to storage systems.

- Q: What is the thickness of the aluminum alloy window frame?

- The national standard "Aluminum Alloy window" has been specified, aluminum wall thickness not less than 1.2 mm. In other words, the main wall thickness of ordinary aluminum alloy window structure should not be less than 1.2 mm, the main wall thickness of the door structure profiles should not be less than 2 mm.

- Q: Calculation of heat dissipation of aluminium profile radiator

- I do not understand this, I am a hardware maintenance, you know that copper is better than aluminum heat conductivity, so most of the notebook is made of copper heat sink, desktop more aluminum

- Q: Can aluminum profiles be used in display shelving and racking systems?

- Yes, aluminum profiles can be used in display shelving and racking systems. Aluminum profiles offer various benefits such as lightweight, durability, and versatility, making them suitable for these applications. They can be easily customized, assembled, and adjusted to meet specific shelving and racking requirements. Additionally, aluminum profiles provide an aesthetically pleasing and modern look to the display shelving and racking systems.

- Q: How do you prevent galvanic corrosion in marine environments with aluminum profiles?

- One way to prevent galvanic corrosion in marine environments with aluminum profiles is by using sacrificial anodes made of a different, more active metal. These anodes, typically made of zinc or magnesium, are connected to the aluminum profiles and act as a sacrificial material that corrodes instead of the aluminum. This helps in protecting the aluminum profiles from galvanic corrosion. Additionally, proper insulation and coating of the aluminum profiles can also be effective in preventing direct contact with other metals and reducing the risk of galvanic corrosion.

- Q: What are the limitations of using aluminum profiles?

- When using aluminum profiles in various applications, it is important to take into account several limitations. First and foremost, heavy-duty or high-stress applications may not be suitable for aluminum profiles. Despite being a lightweight material, aluminum may not possess the same level of strength and rigidity as metals like steel, making it unable to withstand heavy loads or extreme forces. In addition, aluminum profiles are vulnerable to corrosion. While aluminum does have natural corrosion resistance due to the formation of a protective oxide layer, certain environments, especially those with high levels of moisture or chemicals, can still cause deterioration over time, compromising the profiles' structural integrity. Furthermore, aluminum has a relatively low melting point, which makes it more susceptible to heat damage compared to other metals. In applications involving high temperatures, such as certain industrial processes, aluminum profiles may not be the most suitable choice. Moreover, aluminum profiles may have limited design flexibility compared to other materials. While aluminum can be extruded into various shapes and sizes, it may not offer the same level of customization as materials like steel. This can be a constraint when attempting to achieve complex or intricate designs. Lastly, cost can also be a limiting factor when considering aluminum profiles. While aluminum is a widely available and cost-effective material, it may not be the most economical choice for certain applications. In cases where higher strength or specialized properties are required, alternative materials may prove to be more cost-efficient. In conclusion, while aluminum profiles offer numerous advantages such as being lightweight, corrosion-resistant, and affordable, it is crucial to consider these limitations before selecting them for specific applications. Evaluating the load requirements, environmental conditions, design constraints, and budgetary considerations will help determine if aluminum profiles are the most suitable option.

- Q: Can aluminum profiles be used for signage?

- Yes, aluminum profiles can be used for signage. Aluminum is a versatile and durable material that is commonly used for various signage applications. It offers several advantages such as being lightweight, corrosion-resistant, and easy to work with. Aluminum profiles can be easily formed into different shapes and sizes, making them suitable for a wide range of signage requirements. Additionally, aluminum profiles can be powder coated or painted to achieve the desired color and finish, enhancing the overall appearance of the signage. Moreover, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for signage projects. Overall, aluminum profiles are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: What are the different surface embossing options for aluminum profiles?

- Aluminum profiles offer a variety of surface embossing options, each with its own unique textures and patterns. Some commonly used options include: 1. Diamond pattern: This option creates a diamond-shaped pattern on the profile's surface, providing both visual appeal and improved grip. It is ideal for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. It is often used in applications where aesthetics play a crucial role, such as architectural facades or interior design elements. 3. Hammer tone pattern: This option gives the aluminum profile a hammered texture, providing a distinctive and rustic appearance. It is popular in decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and look of natural wood. It is commonly chosen for applications like window frames or doors when a traditional or natural appearance is desired. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the profile's surface. It is frequently used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's worth noting that these embossing options can be customized or combined to meet specific design requirements. Manufacturers may offer additional options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

Send your message to us

Custom CNC Processed Aluminum Channel Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords